Thin film transistor

A thin film transistor and carbon nanotube thin film technology, applied in the field of thin film transistors based on carbon nanotubes, can solve the problems of poor transmission performance, poor flexibility of thin film transistors, unfavorable thin film transistors, etc., and achieve excellent mechanical properties, good toughness and mechanical strength. , the effect of improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

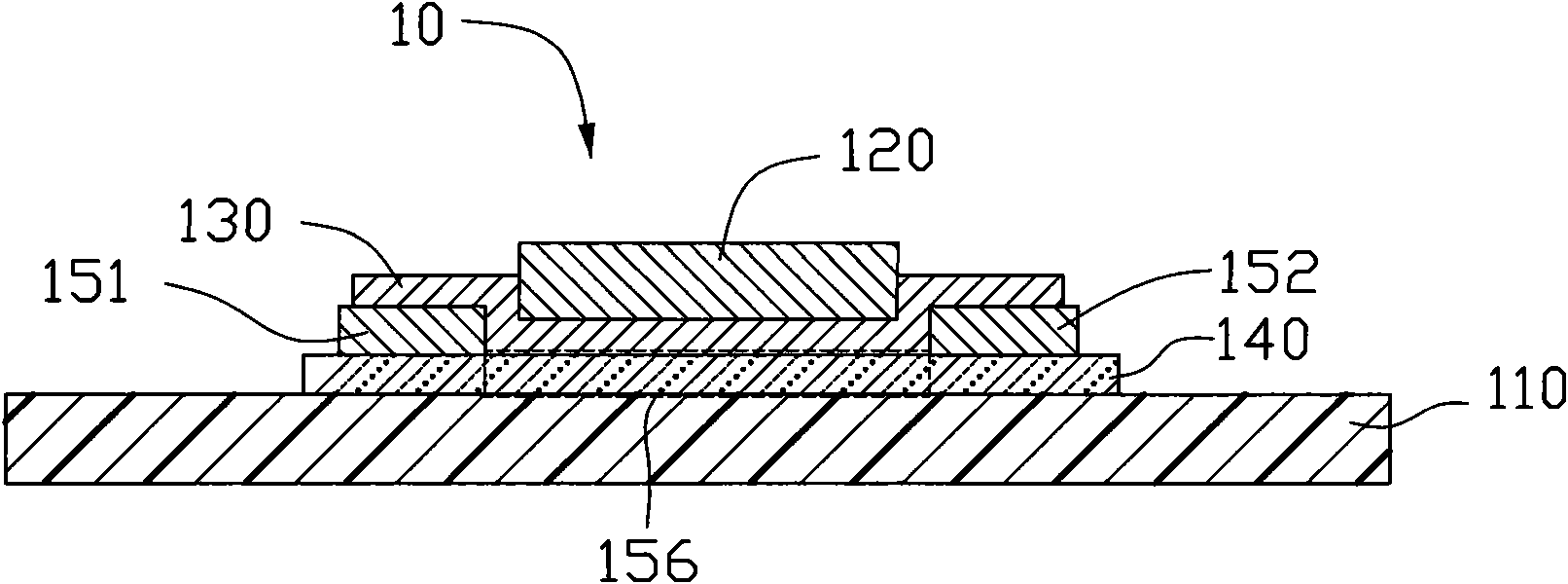

[0012] The thin film transistor provided by the embodiment of the technical solution will be described in detail below with reference to the accompanying drawings.

[0013] see figure 1 , the first embodiment of the technical solution provides a thin film transistor 10, the thin film transistor 10 is a top gate type, which includes a semiconductor layer 140, a source 151, a drain 152, an insulating layer 130 and a gate 120 . The TFT 10 is formed on a surface of an insulating substrate 110 .

[0014] The semiconductor layer 140 is disposed on the surface of the insulating substrate 110 . The source 151 and the drain 152 are spaced apart on the surface of the semiconductor layer 140 . The insulating layer 130 is disposed on the surface of the semiconductor layer 140 . The gate 120 is disposed on the surface of the insulating layer 130 and is insulated from the semiconductor layer 140 and the source 151 and the drain 152 through the insulating layer 130 . A region of the sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com