Imitation electroplating coating

An imitation electroplating and coating technology, applied in the field of imitation electroplating coatings, can solve problems such as skin allergies, carcinogenicity, air and water pollution, and achieve the effects of good environmental protection, strong adhesion and good brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

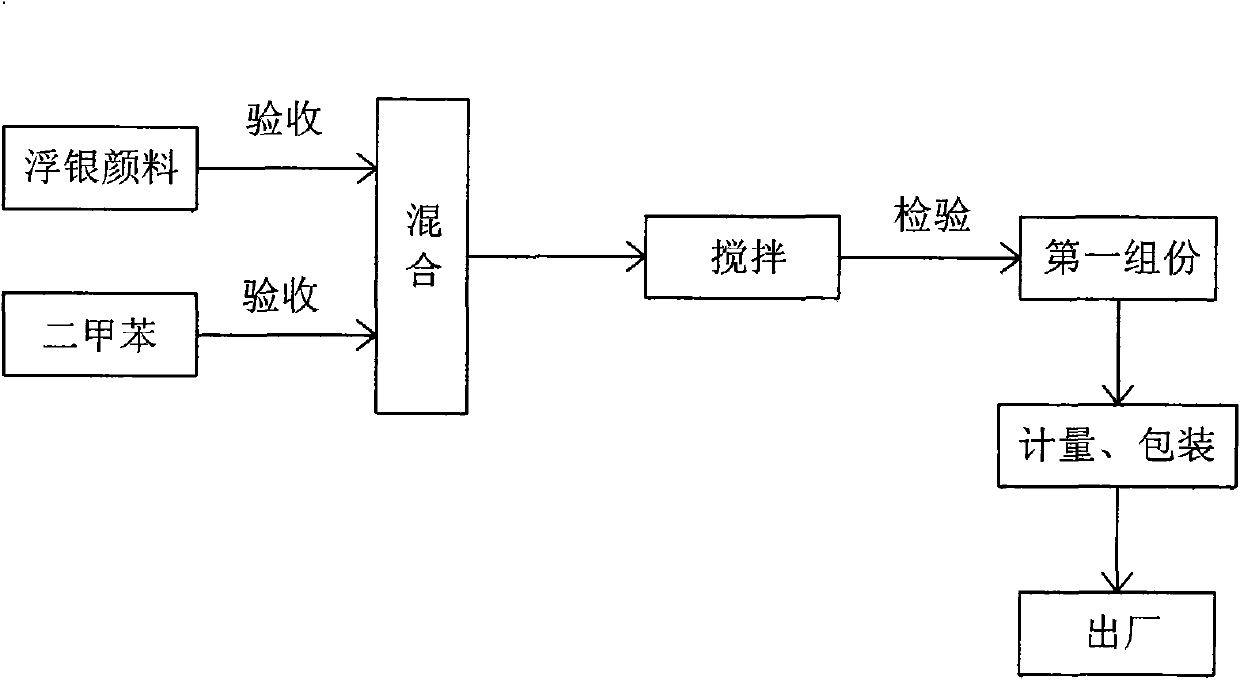

Image

Examples

Embodiment 1

[0106] The present embodiment is optimal formula, and its first component parts by weight are formed as follows:

[0107] 3 parts of floating silver paint

[0108] 27 parts of xylene;

[0109] The second component parts by weight are composed as follows:

[0110] Amino resin 5 parts

[0111] Low acid value acrylic resin 23 parts

[0112] Butyl acetate 0.6 parts

[0113] Xylene 0.6 parts

[0114] Low acid value adhesion promoter 0.2 parts

[0115] Low acid value conductive agent 0.15 parts.

[0116] The production process, inspection requirements, usage methods and other relevant contents are as mentioned above.

Embodiment 2

[0118] The first component parts by weight of the present embodiment are composed as follows:

[0119] 3 parts of floating silver paint

[0120] 27 parts of xylene;

[0121] The second component parts by weight are composed as follows:

[0122] 4 parts amino resin

[0123] Low acid value acrylic resin 24 parts

[0124] Butyl acetate 0.6 parts

[0125] Xylene 0.6 parts

[0126] Low acid value adhesion promoter 0.2 parts

[0127] Low acid value conductive agent 0.15 parts.

[0128] The production process, inspection requirements, usage methods and other relevant contents are as mentioned above.

Embodiment 3

[0130] The first component parts by weight of the present embodiment are composed as follows:

[0131] 3 parts of floating silver paint

[0132] 27 parts of xylene;

[0133] The second component parts by weight are composed as follows:

[0134] Amino resin 6 parts

[0135] Low acid value acrylic resin 22 parts

[0136] Butyl acetate 0.6 parts

[0137] Xylene 0.6 parts

[0138] Low acid value adhesion promoter 0.2 parts

[0139] Low acid value conductive agent 0.15 parts.

[0140] The production process, inspection requirements, usage methods and other relevant contents are as mentioned above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com