Connecting structure for vehicular generator for eliminating coupling of mechanical vibration noise

A noise coupling and connection structure technology, applied in the direction of power devices, vehicle parts, electric power devices, etc., can solve problems such as resonance and noise, and achieve the effects of eliminating noise, avoiding resonance, and improving vibration characteristics and noise characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

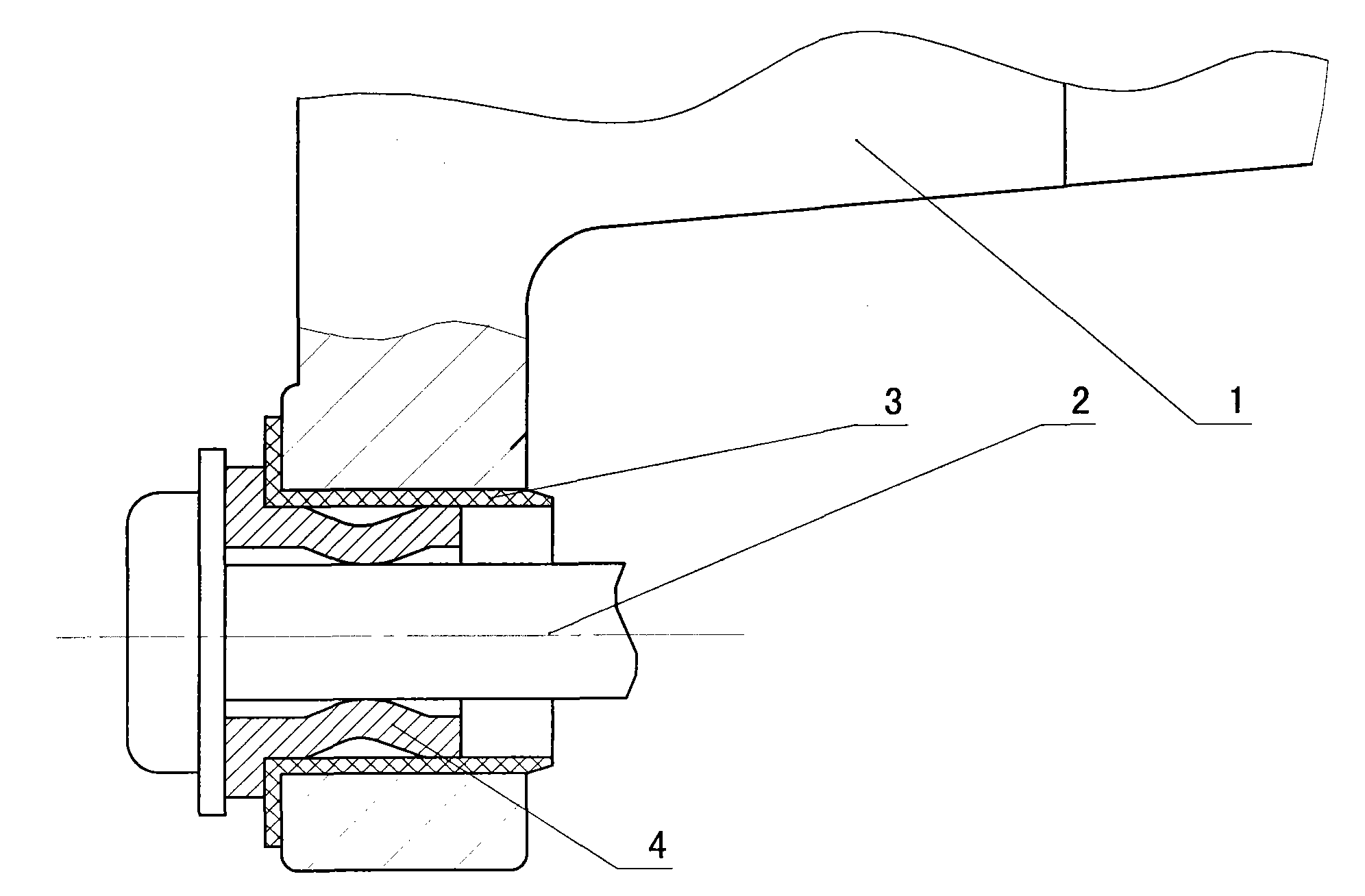

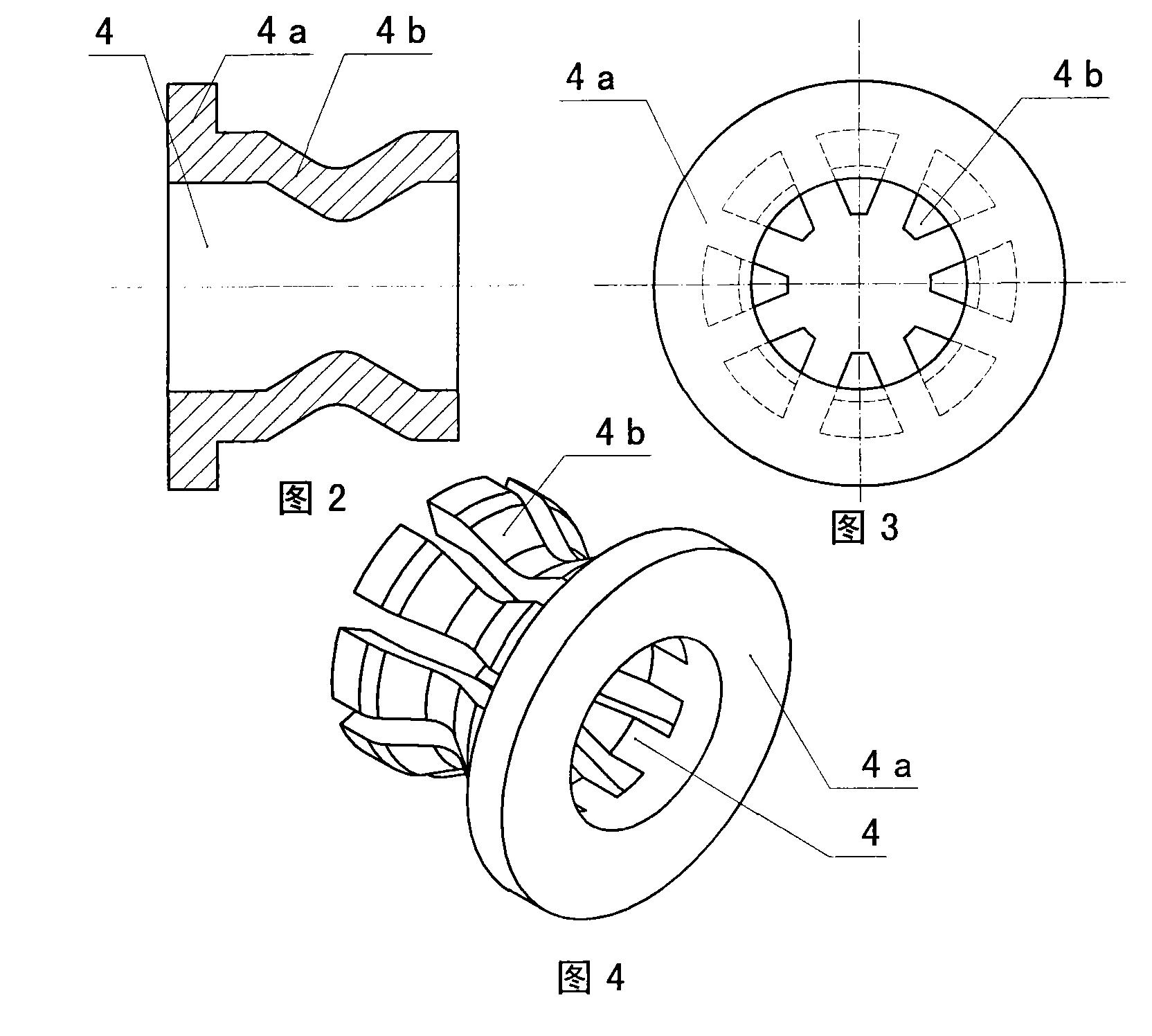

[0013] As shown in the accompanying drawings, the present invention has a hanging foot 1 of a generator installation bracket, and a compensation sleeve 3 is installed in the hanging foot hole of the hanging foot 1, and a through bolt 2 is installed in the compensation sleeve 3; the compensation sleeve 3 adopts PC engineering Made of plastic, an elastic element 4 is installed between the compensation sleeve 3 and the through bolt 2 to reduce the vibration of the engine during operation and avoid the resonance between the generator and the engine; the elastic element 4 has a circular base 4a, and the The base 4a is provided with 6 curved elastic supporting pieces 4b, and the number of elastic supporting pieces 4b is not limited to 6, which can be increased or decreased according to actual needs; the elastic supporting pieces 4b on the elastic element 4 are tightly wrapped on the through bolt 2 , so that the through bolt 2 is well assembled in the hanging foot hole of the hanging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com