Dissipating device

A technology of heat dissipation device and heat dissipation fins, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of increasing the combined noise of heat dissipation devices, increasing fan noise or abnormal sound, etc. Efficiency, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

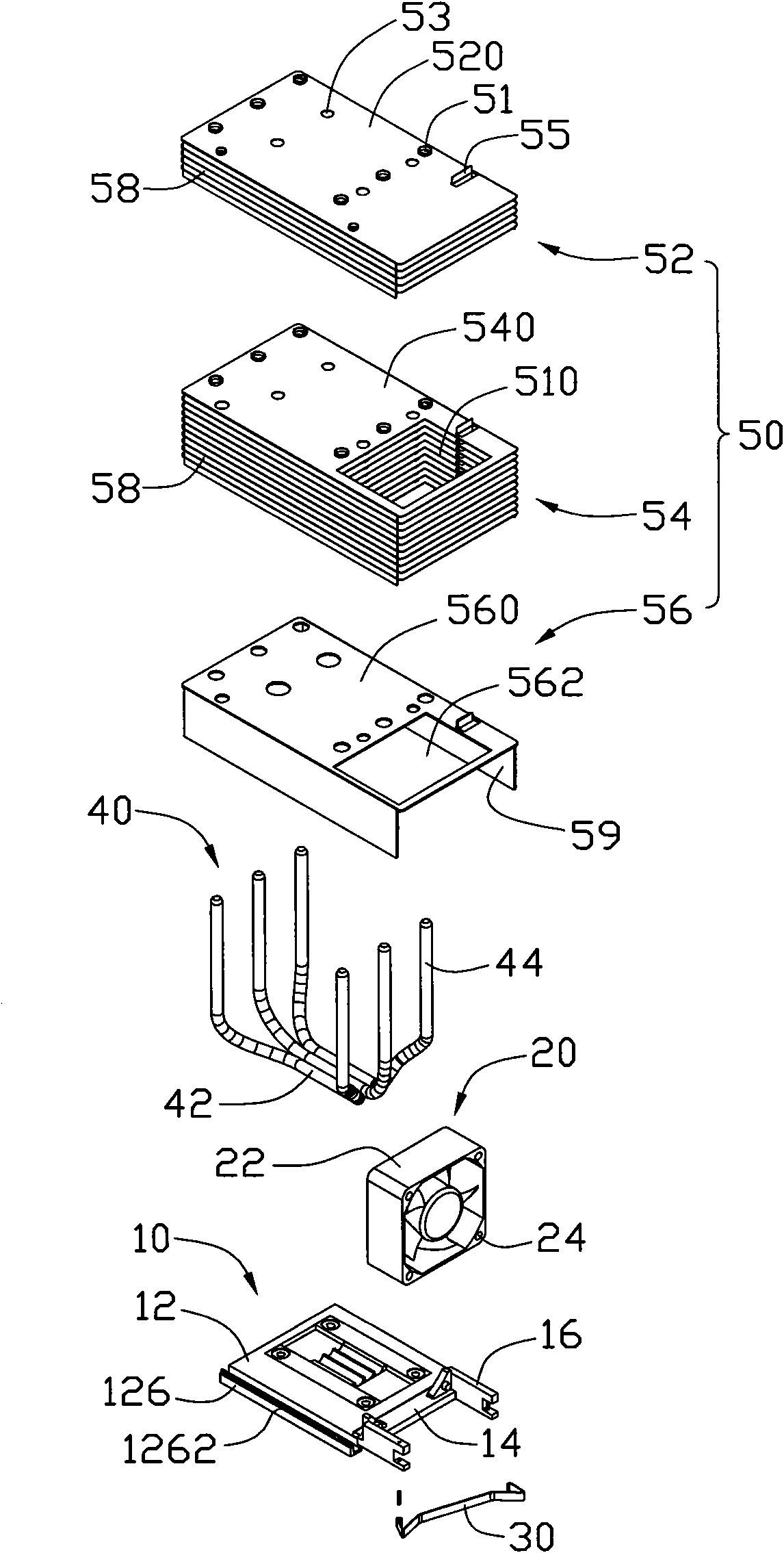

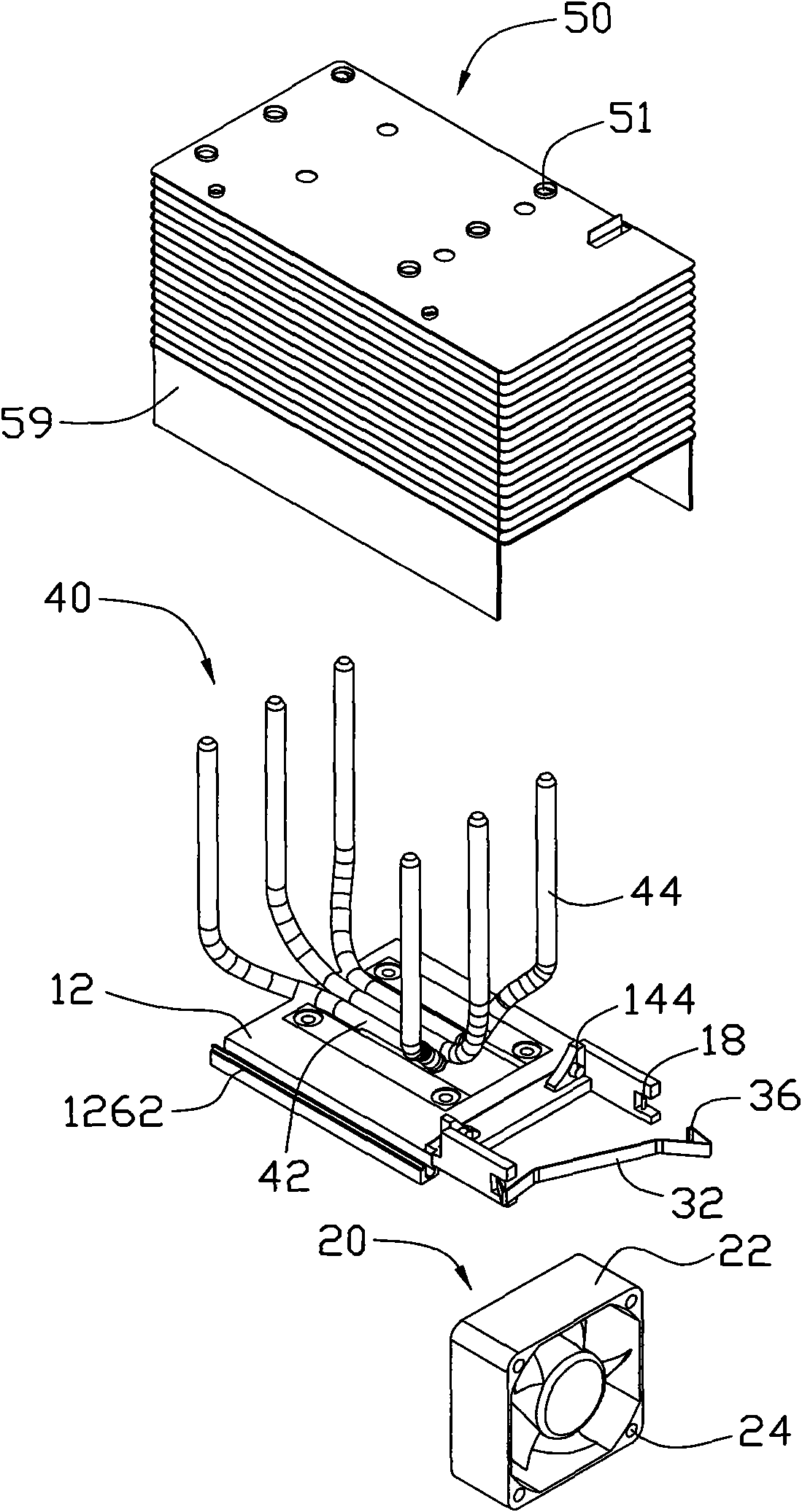

[0014] see figure 1 , the heat dissipation device of the present invention is used to dissipate heat to an electronic component (not shown), which includes a base 10 in contact with the electronic component, a fan 20 placed on the base 10, and a buckle for fixing the fan 20 to the base 10 Tool 30 , several heat pipes 40 installed on the base 10 and a cooling fin set 50 placed on the base 10 and through which the heat pipes 40 pass.

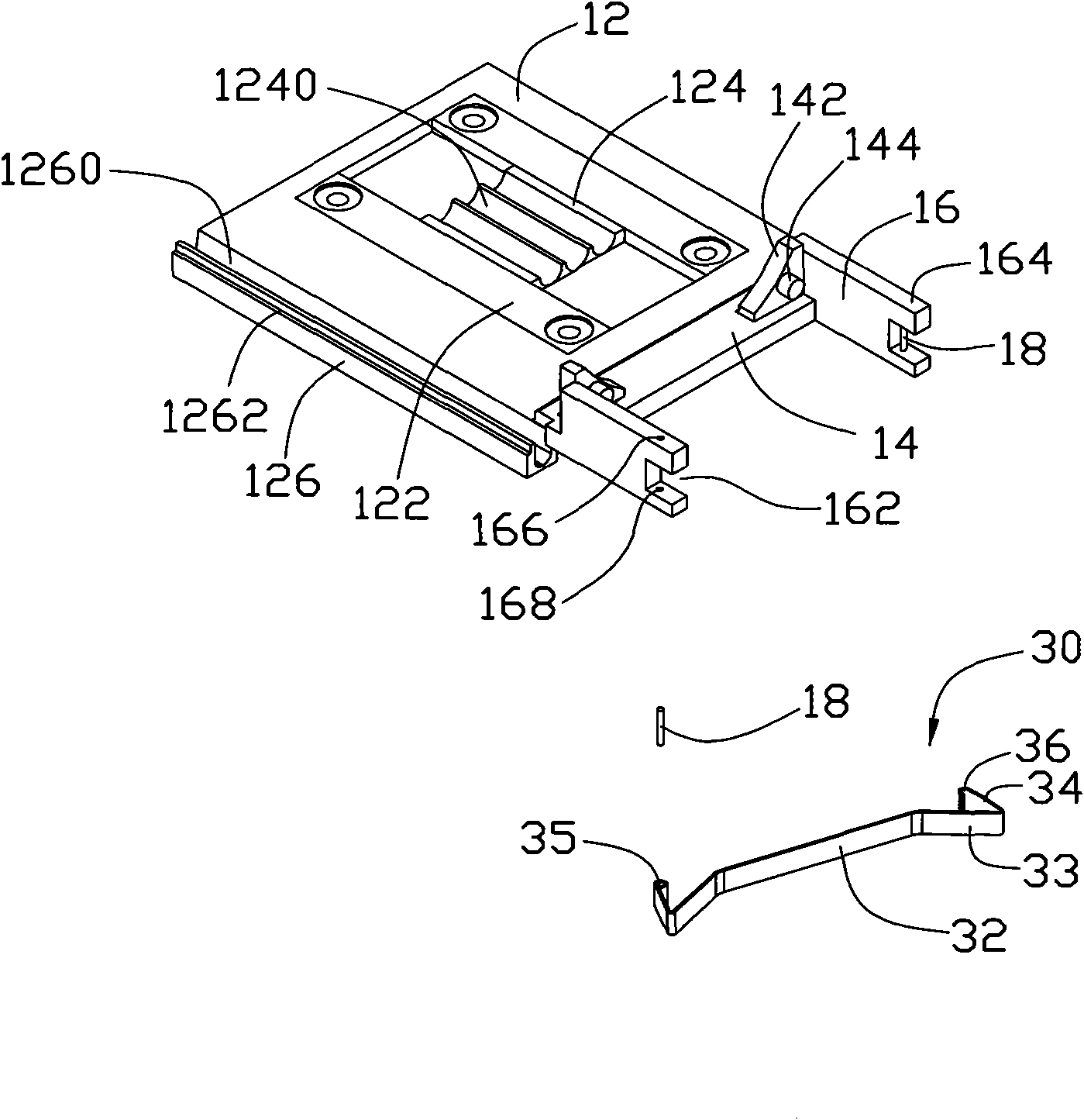

[0015] The above-mentioned base 10 includes a substantially square body 12, a connecting plate 14 extending horizontally outward from one end of the body 12, and two mounting plates extending outward horizontally from opposite ends of the connecting plate 14 perpendicular to the connecting plate 14. plate 16.

[0016] Please also see figure 2 A rectangular opening (not shown) is defined on the body 12 of the base 10 for receiving a substrate 122 . The base plate 122 is close to one side of the body 12 of the base 10 and away from the other opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com