Flow sensor of ultrasonic water meter and heat meter

A flow sensor and ultrasonic technology, applied in the field of heat meter flow sensor, ultrasonic water meter, can solve the problems of difficult meter calibration, difficult to achieve accuracy, difficult data correction, etc., to achieve accurate measurement, simple structure, and small pressure loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

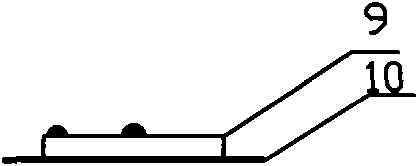

[0020] Accompanying drawing is a kind of concrete embodiment of the present invention, present embodiment ultrasonic water meter, heat meter flow sensor: comprise sensor housing, ultrasonic transducer 2, ultrasonic reflector 4 and the rectifier tube between ultrasonic transducer 2 , it is characterized in that: the ultrasonic reflector 4 is fixed on the bottom of the sensor housing with screws, the rectifying straight pipe has rectifying corrugations 5, and the inner wall of the rectifying straight pipe can be processed into an inner wall according to the function of the machining equipment. Thread-like or other rough internal surface shape, in this example we machined it into a double thread internal thread. The rectification corrugation 5 includes a variety of processing and forming methods: first, the inner surface of the rectification tube is continuous grooves; second, internal threads are processed on the inner surface of the rectification tube; third, protrusions are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com