Liquid phase-change brake

A brake, liquid phase technology, applied in the direction of brake type, mechanical equipment, etc., can solve the problems of complex device structure, troublesome replacement of friction elements, and high cost, and achieve the effects of simple manufacturing process, excellent braking performance, and good heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

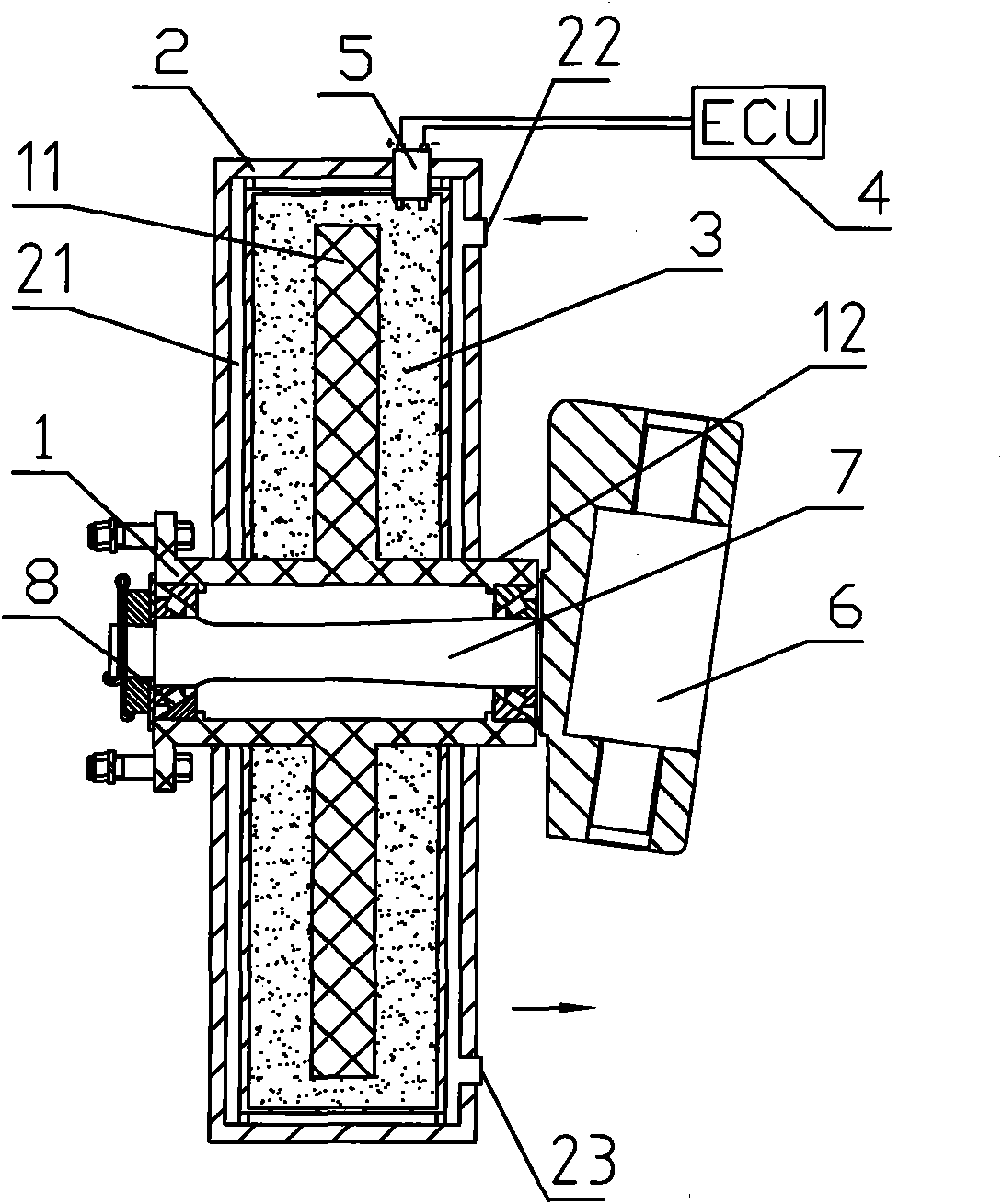

[0019] Embodiment one, such as figure 1 As shown, the liquid phase change brake includes a brake frame and a brake disc 1, the brake frame is a sealed box 2, the friction part 11 of the brake disc 1 passes through the inner space of the sealed box 2, The sealing box is a disc structure, and the middle part of the sealing box 2 extends to the shaft ring wall 12 of the brake disc, so that the friction part 1 is all in the sealing box 2, and the shaft of the sealing box and the brake disc The body ring wall junction is movable and sealed. The inner space of the sealed box 2 is filled with a reversible phase change liquid. Electrical signal socket 5 for electrical connection. A cooling channel 21 and a medium inlet 22 and a medium outlet 23 for communicating with an external cooling medium are also provided in the wall of the sealed box 2 . The medium inlet and medium outlet are respectively arranged on both sides of the sealed box. Among the figure, 6 is a steering knuckle, 7 ...

Embodiment 2

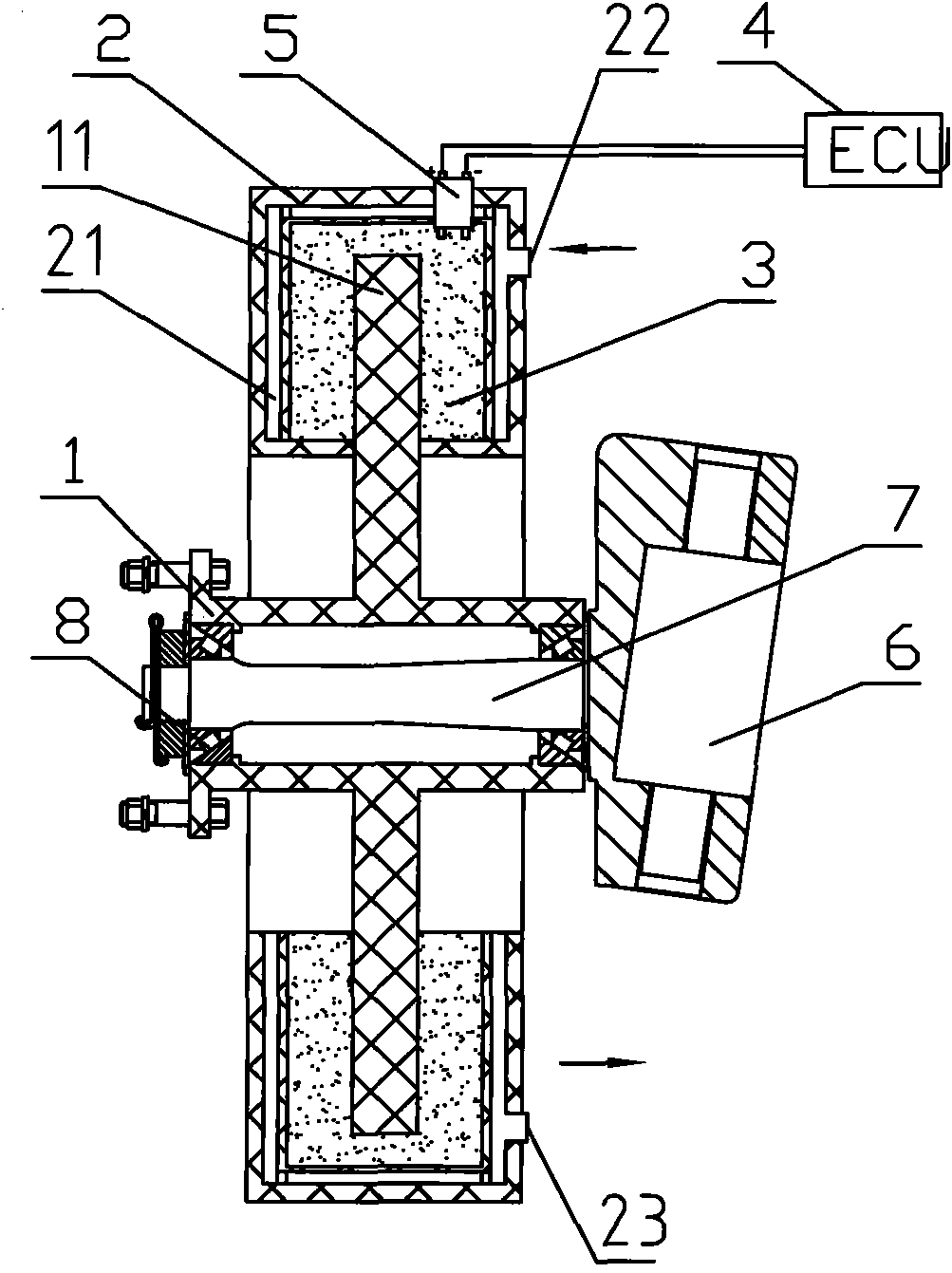

[0020] Embodiment two, such as figure 2 As shown, the liquid phase change brake includes a brake frame and a brake disc 1, the brake frame is a sealed box 2, the friction part 11 of the brake disc 1 passes through the inner space of the sealed box 2, The sealed box body is a disc structure, and the ring surface of the friction part 1 penetrates into the sealed box body 2 . The middle part of the sealing box 2 does not extend to the shaft ring wall of the brake disc, and the joint between the sealing box 2 and the friction part 1 of the brake disc is movable and sealed, and the inner space of the sealing box is filled with a reversible phase change liquid , in this embodiment, the reversible phase change fluid is electrorheological fluid 3 , and an electrical signal socket 5 electrically connected to an external control system 4 is also provided in the sealed box. A cooling channel 21 and a medium inlet 22 and a medium outlet 23 for communicating with an external cooling medi...

Embodiment 3

[0027] Embodiment 3. The difference between this embodiment and Embodiments 1 and 2 is that the reversible phase change liquid and its corresponding trigger device are different. In this embodiment, the reversible phase change liquid is a magneto-rheological liquid, and the trigger device is a magnetic Magnetic pole plate assembly on both sides of the rheological fluid. Such as image 3 As shown, the liquid phase change brake includes a brake frame and a brake disc 1, the brake frame is a sealed box 2, the friction part 11 of the brake disc 1 passes through the inner space of the sealed box 2, The sealing box is a disc structure, and the middle part of the sealing box 2 extends to the shaft ring wall 12 of the brake disc, so that the friction part 1 is all in the sealing box 2, and the shaft of the sealing box and the brake disc The body ring wall joint is movable and sealed, and the inner space of the sealed box 2 is filled with magnetorheological fluid 91, and there are als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com