Parabolic pad guide bearing for main shaft of vertical water turbine

A water turbine and parabolic technology, applied in mechanical equipment, hydroelectric power generation, engine components, etc., can solve the problems of inconvenient cleaning and replacement of cooling pipes, large friction loss, and temperature rise of coolers, and achieve superior dynamic hydraulic performance of bearings. Large, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

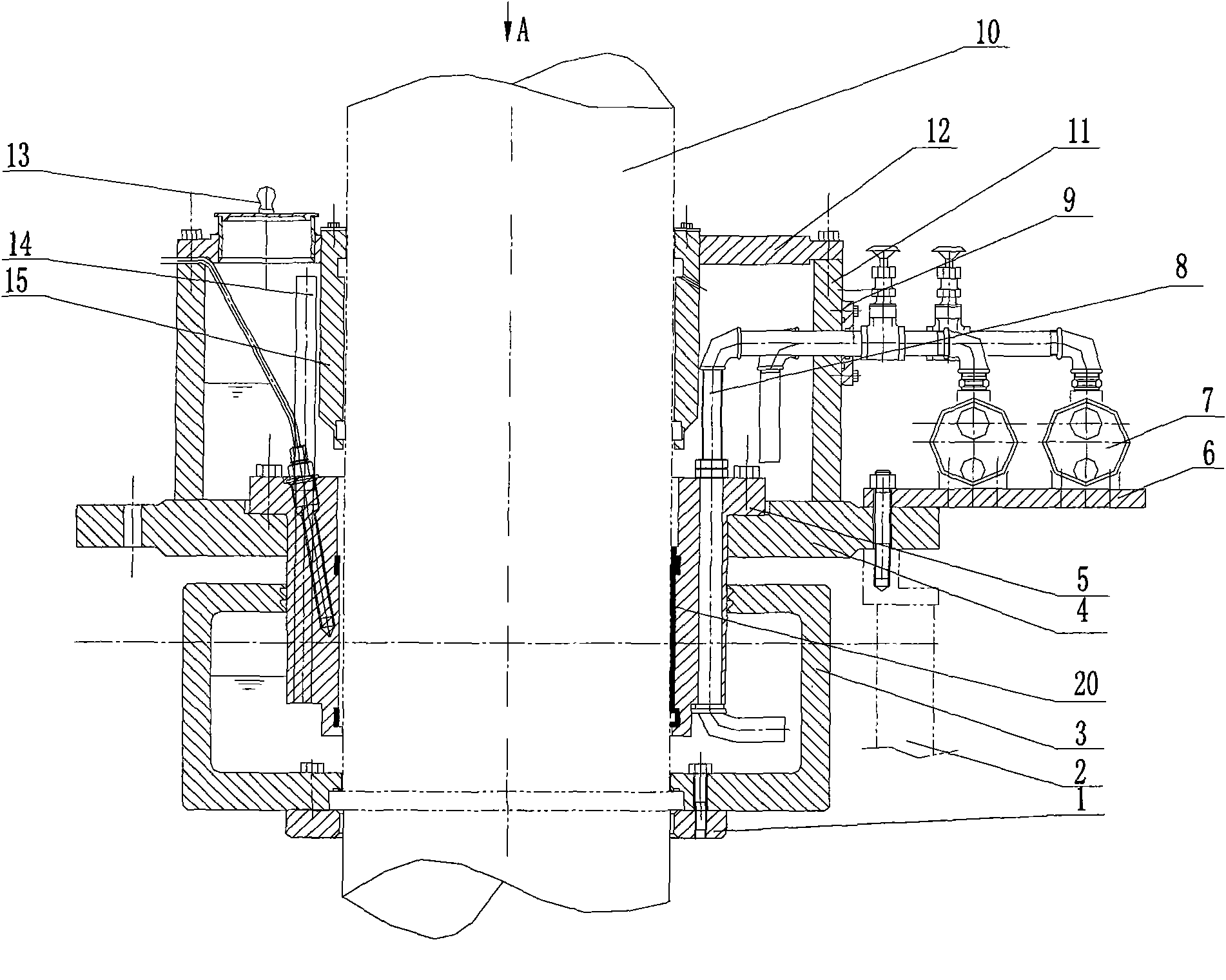

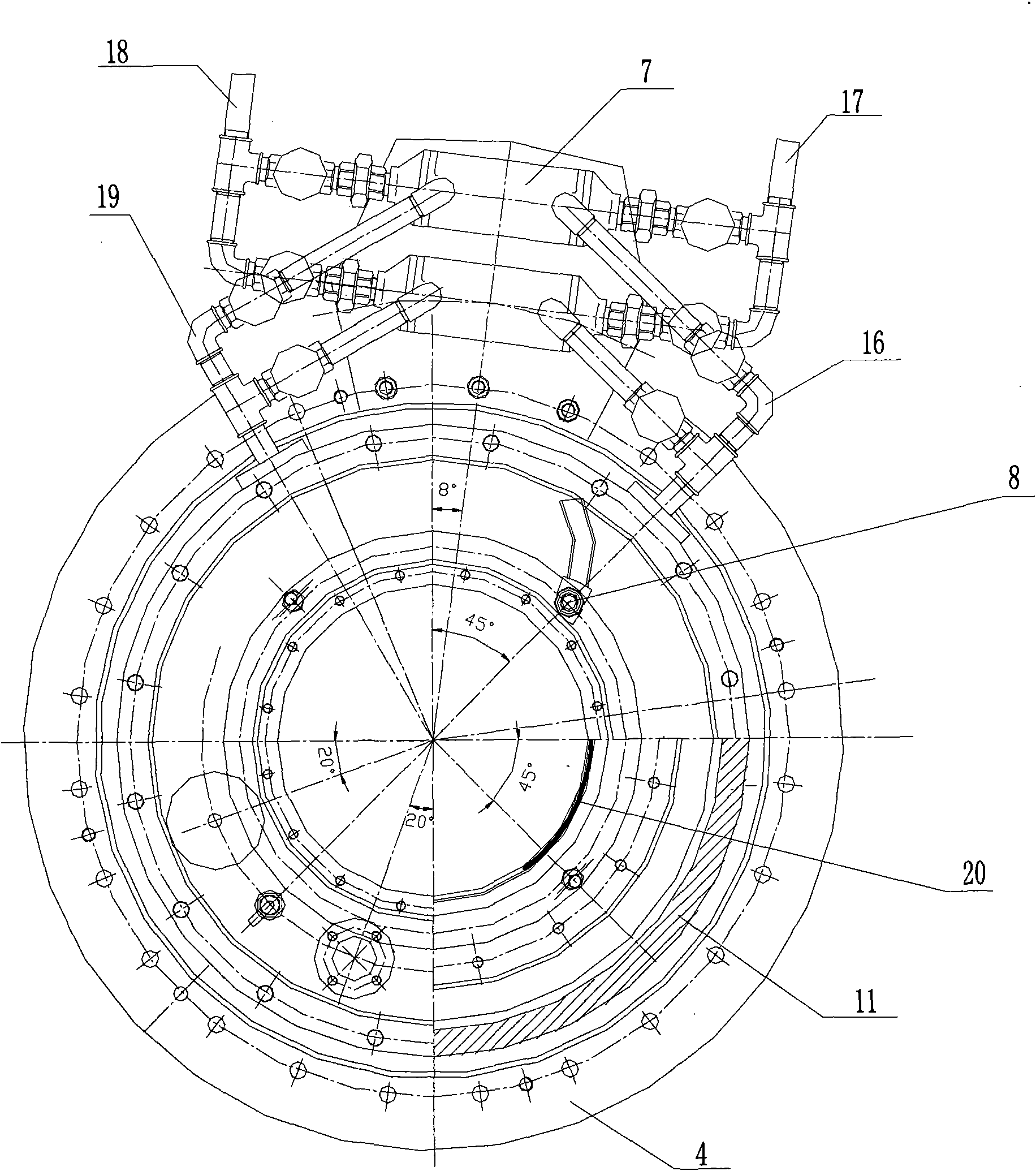

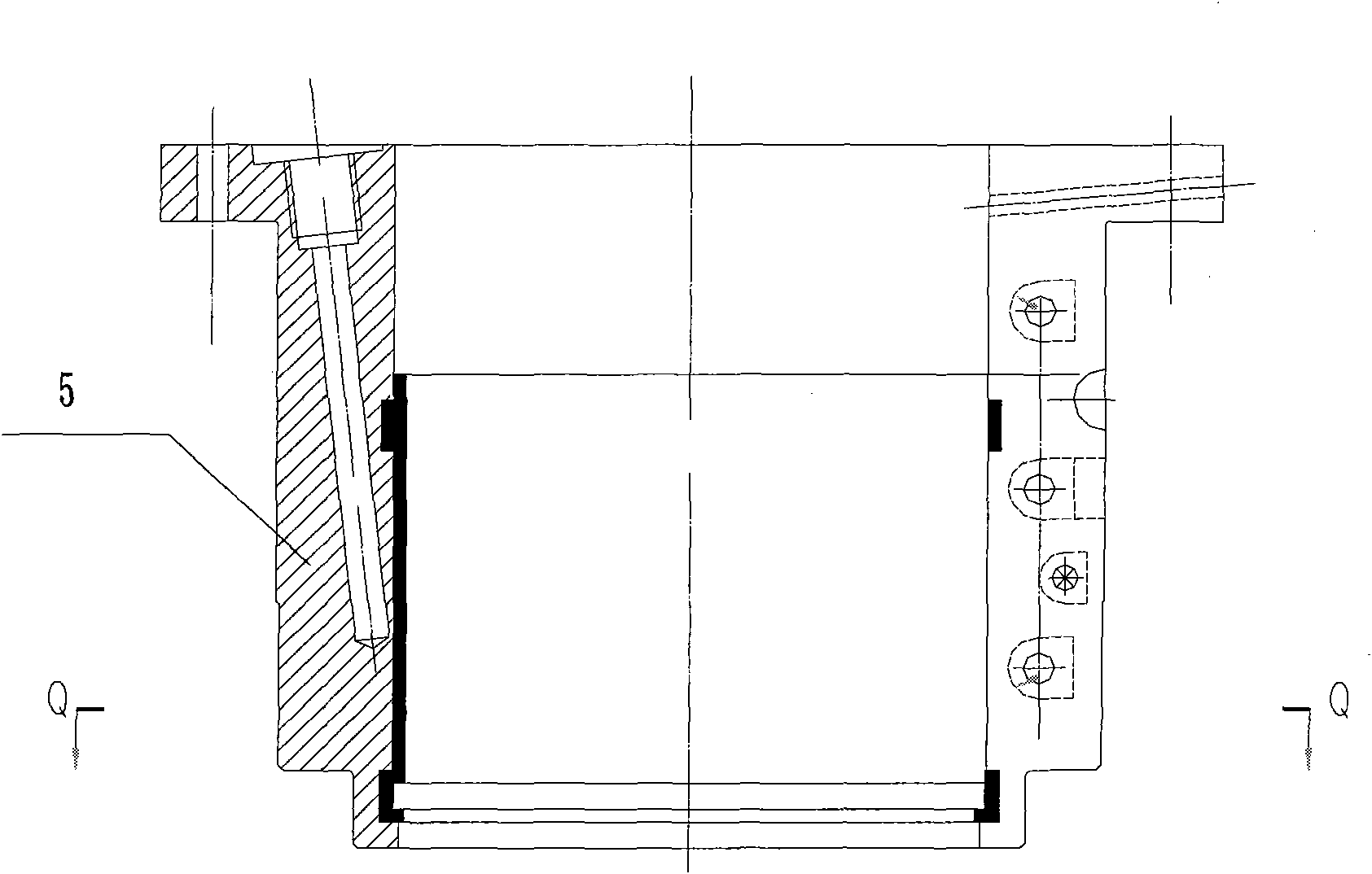

[0018] see Figure 1 to Figure 6 , an annular bearing seat 4 is installed on the top cover 2 of the water turbine, and an annular bearing body 5 is fixed on the bearing seat. . The bearing shell 20 of the main shaft 10 is inlaid inside the bearing body. The bearing shell is uniformly distributed in four petals in the circumferential direction and is made of Babbitt alloy. Its surface is a parabolic curved surface, and its thickness gradually becomes thinner along the curve direction. A rotating oil basin 3 located at the lower end of the bearing body is installed on the main shaft through a snap ring 1. An upper oil tank 11 and an oil tank cover 12 for closing the upper oil tank are welded on the upper end of the bearing seat. A bearing cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com