Level crossing railway converter

A plane crossing and converter technology, applied in the direction of track, switch, road, etc., can solve problems such as rollover accidents and vehicle shaking, and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

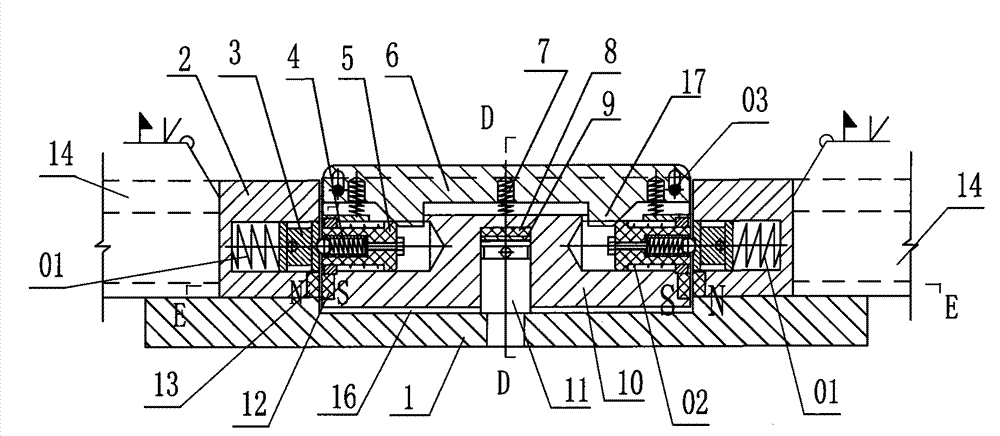

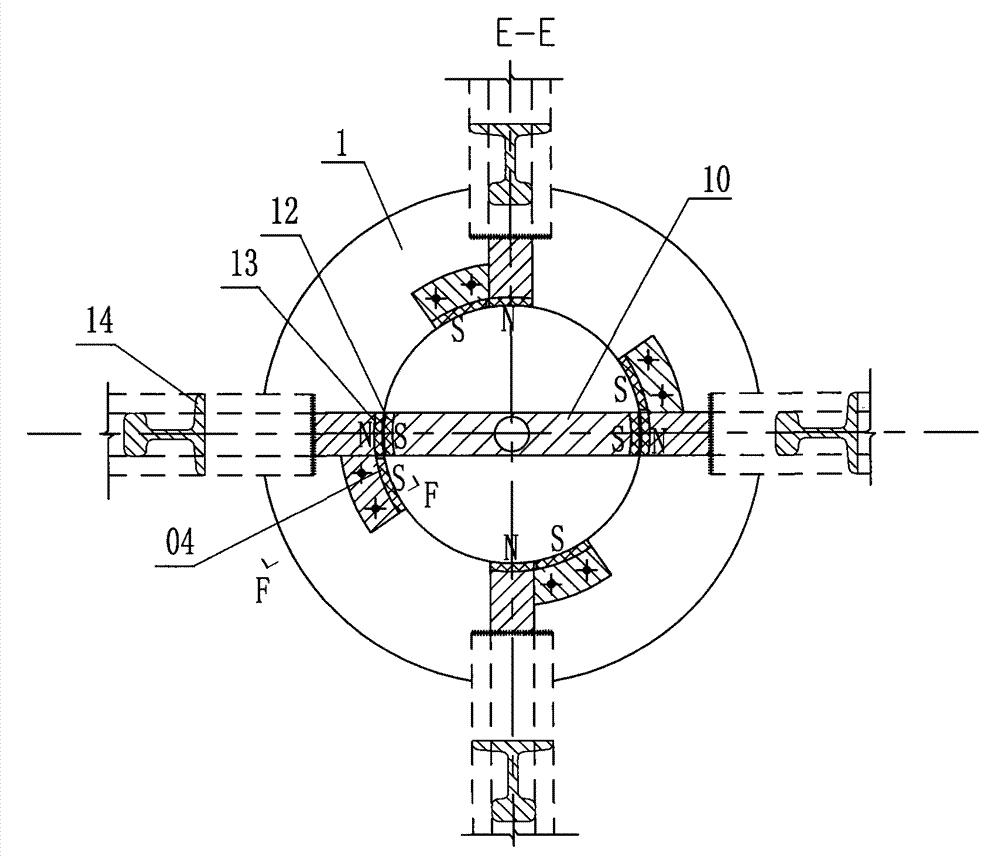

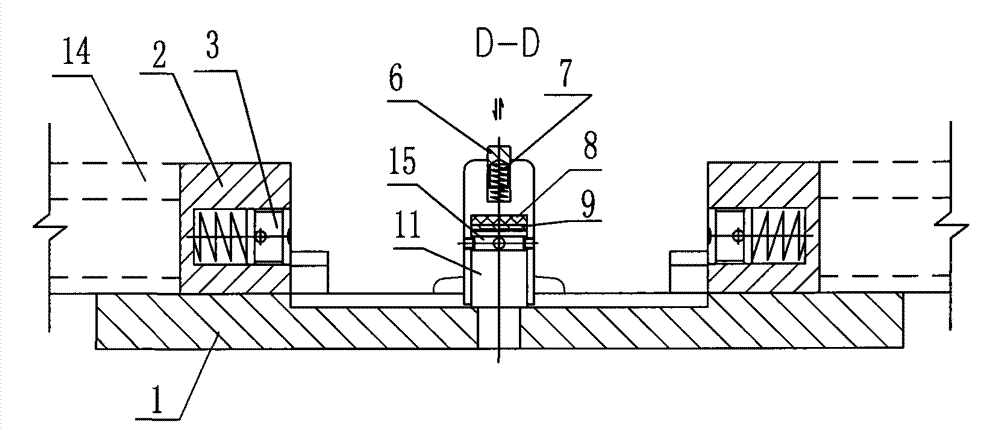

[0022] Figure 1-3 The shown planar cross-track converter includes a base 1 and an in-line rail rotating body 10 horizontally rotatably mounted on the base. The base is provided with a pivot 11, and the center axis of the rail rotating body 10 passes through it. The hole is rotatably assembled on the pivot 11. The central axis hole is a blind hole. Between the bottom of the central axis hole and the shaft end of the pivot, there are elastic body 8 and friction reducing member 9. The pivot 11 and elastic body 8 support The rail rotating body 10 makes an appropriate amount of gap 16 between the bottom surface of the rail rotating body and the base 1 without force, and the gap is eliminated when the pressing body 8 is subjected to pressure from the rail rotating body 10, reducing The friction piece 9 and the gap 16 ensure that the track rotating body 10 can rotate around the pivot 11 flexibly when it is not under pressure. The spring pressing body 8 adopts an elastic rubber pad,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com