Large-sized biogas fermentation device integrating fermentation and gas storage

A biogas fermentation and gas storage technology, applied in biochemical cleaning devices, enzymology/microbiology devices, gas production bioreactors, etc., can solve the problems of low construction efficiency, many pipeline accessories, unstable biogas pressure, etc. The effect of convenient management and maintenance, prevention of biogas leakage, and easy promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

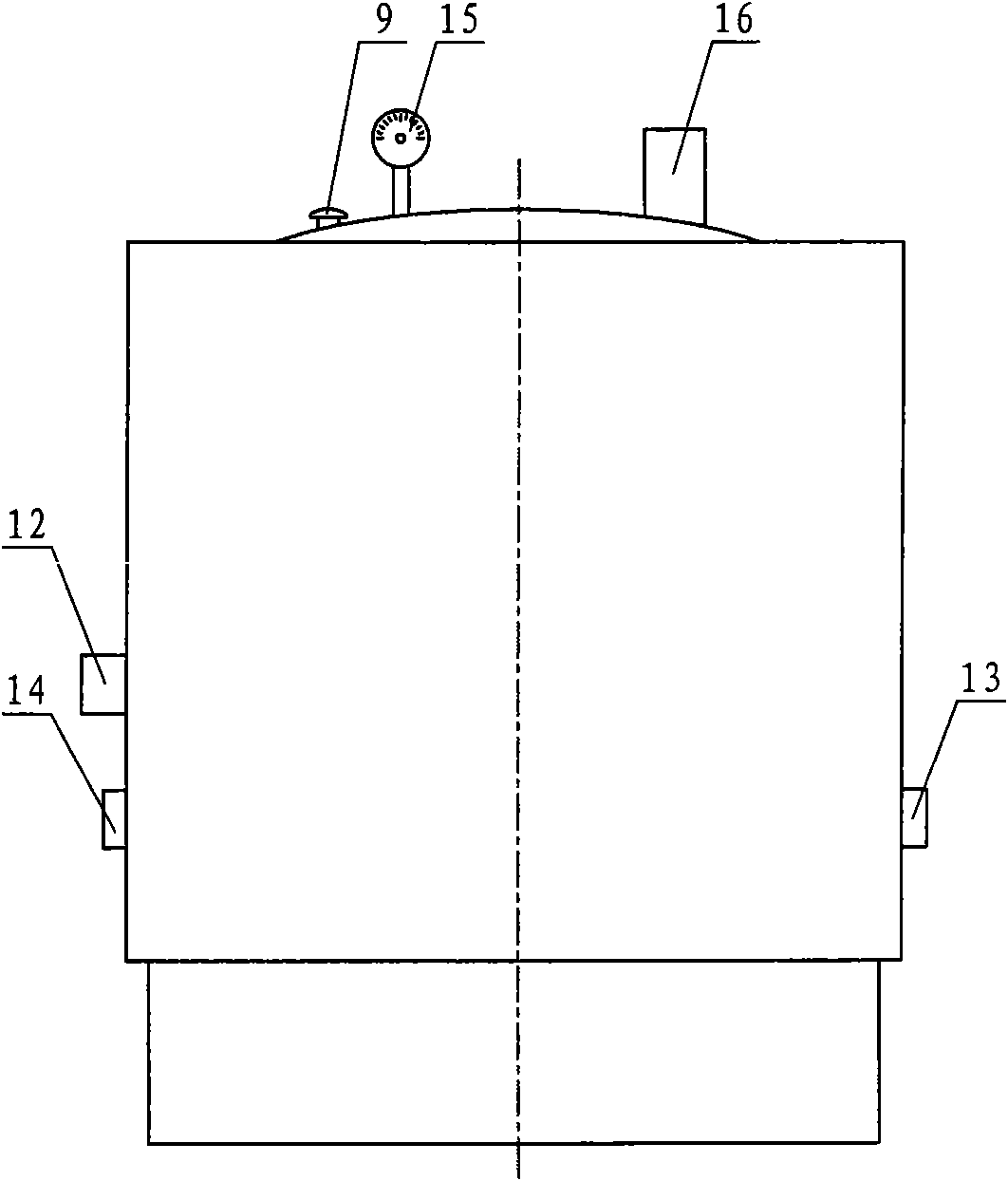

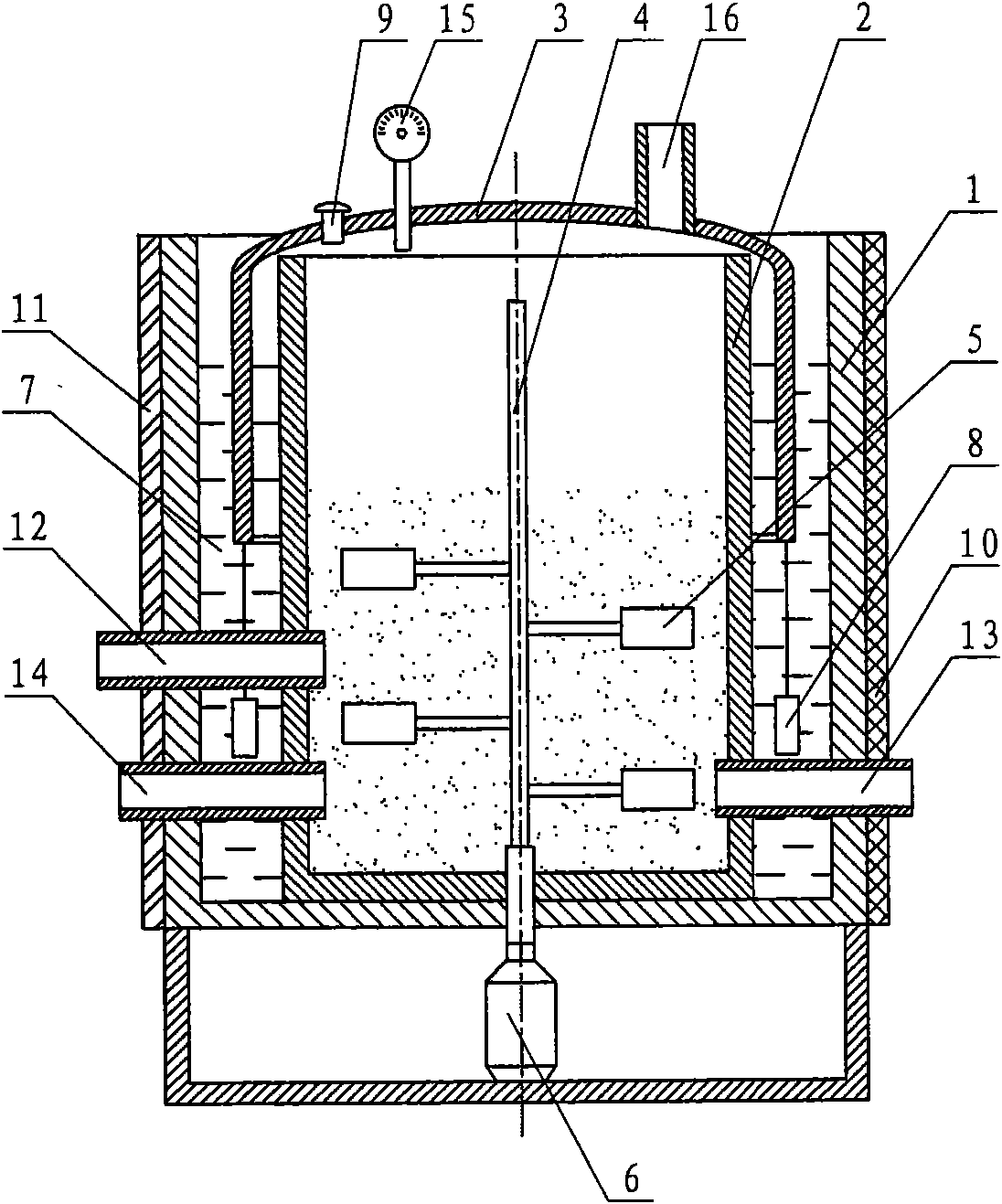

[0017] As shown in the figure: a large-scale biogas fermentation device integrating fermentation and gas storage, consisting of a casing 1, a gas production chamber 2 installed in the casing, and a gas storage floating cover 3 set outside the gas production chamber. In order to fully ferment the raw materials and increase the gas production, the gas production chamber is equipped with a biogas stirring device consisting of a main shaft 4, a stirring blade 5 installed on the main shaft and a motor 6 connected to the main shaft. In order to prevent the biogas in the gas-producing chamber from leaking, water 7 is installed between the shell and the gas-producing chamber. In order to prevent too much biogas and excessive pressure in the air storage floating cover, a counterweight 8 and an air release valve 9 are installed on the upper bottom of the air storage floating cover. In order to ensure the gas production in winter, an insulating layer 10 and a heat absorbing layer 11 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com