Floating washing apparatus

A scrubber and floating body technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agent, etc., can solve the problem of high power consumption, increased energy loss of adjustable-diameter Venturi scrubbers, and weakened pressure drop recovery function and other problems, to achieve the effect of small energy loss, good recovery function, and stable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

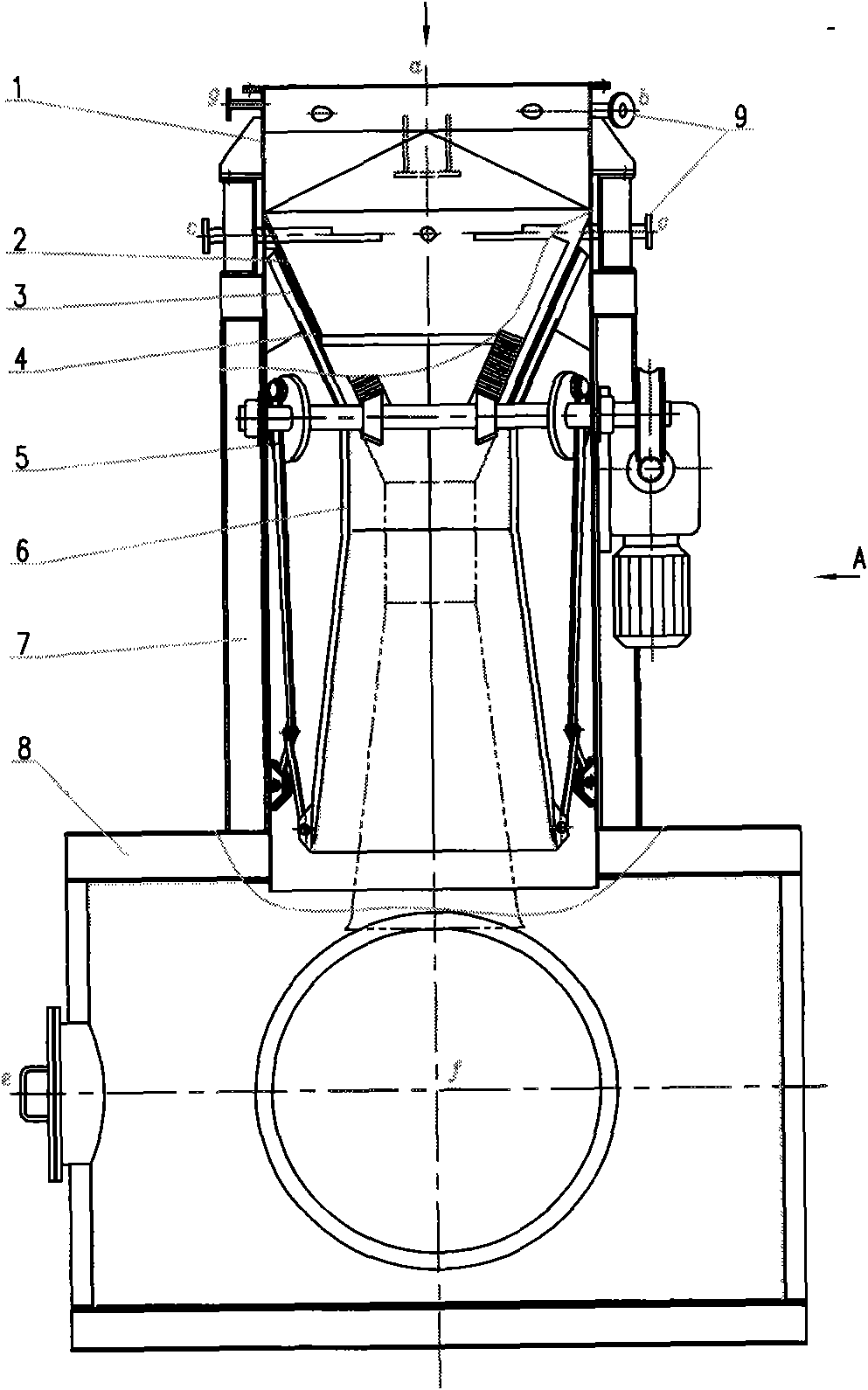

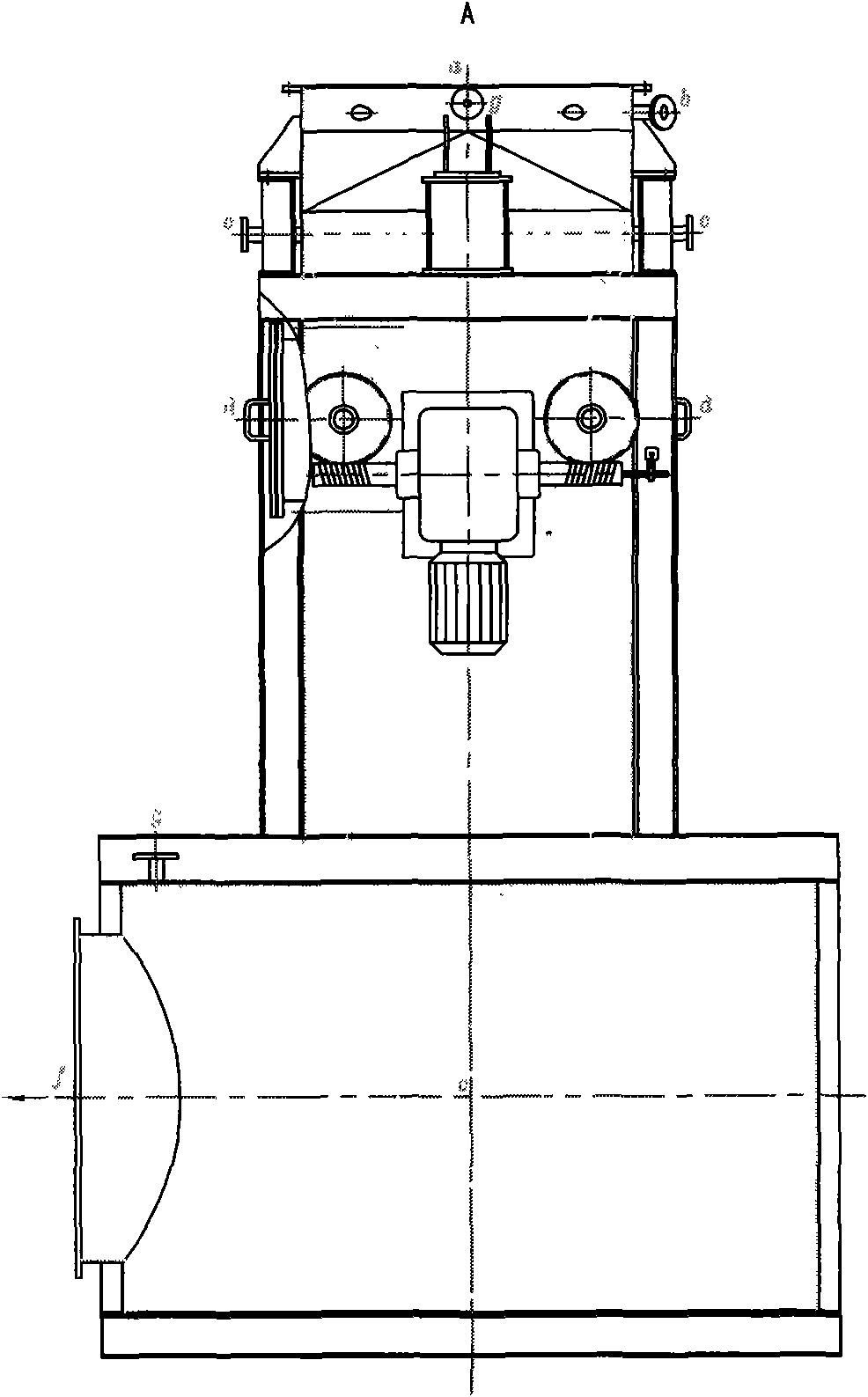

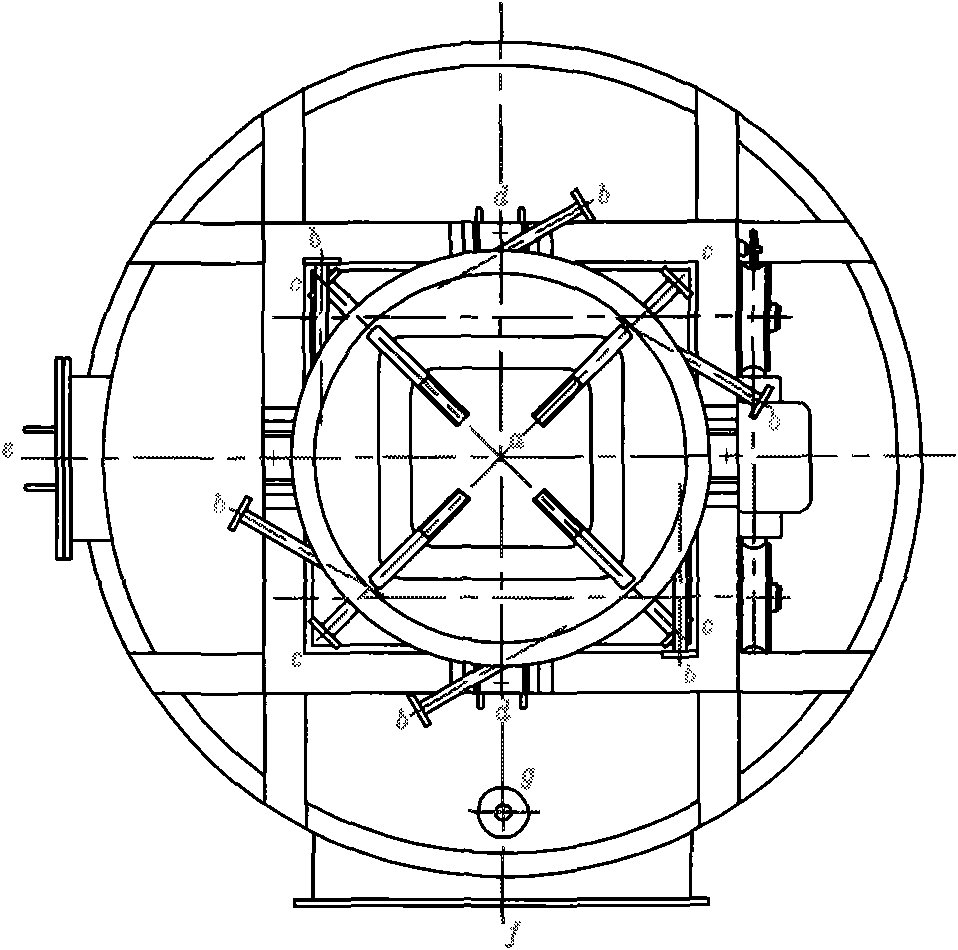

[0027] Attached figure 1 , Attached figure 2 , Attached image 3 It is a structural view of an embodiment of the present invention. The floating scrubber of the embodiment of the present invention is composed of a floating body (6), a floating body guide rail (3), an actuator (5), a rhombus-shaped contraction port (2), a sealing device (4), a frame (7), and an upper box. (1), the lower box (8), the water inlet (9) and other components. In the figure, the top a of the upper box body is the flue gas inlet, and f is the outlet after the flue gas is washed.

[0028] The floating body is composed of four movable petals. The petals can move laterally, but the gap between the petals is sealed with a sealing tape to form a square venturi. On the upper part of the venturi tube, there is a fixed rhombic constriction opening, which is a part of the guide rail, and the floating body moves along the generatrix direction of the rhombic constriction opening. Driven by the actuator, the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com