Portable water mist fire extinguisher

A fire extinguisher and fine water mist technology, applied in fire rescue and other fields, can solve problems such as poor reliability, inconvenient use, complex control system, etc., and achieve the effects of reduced energy consumption, simplified structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

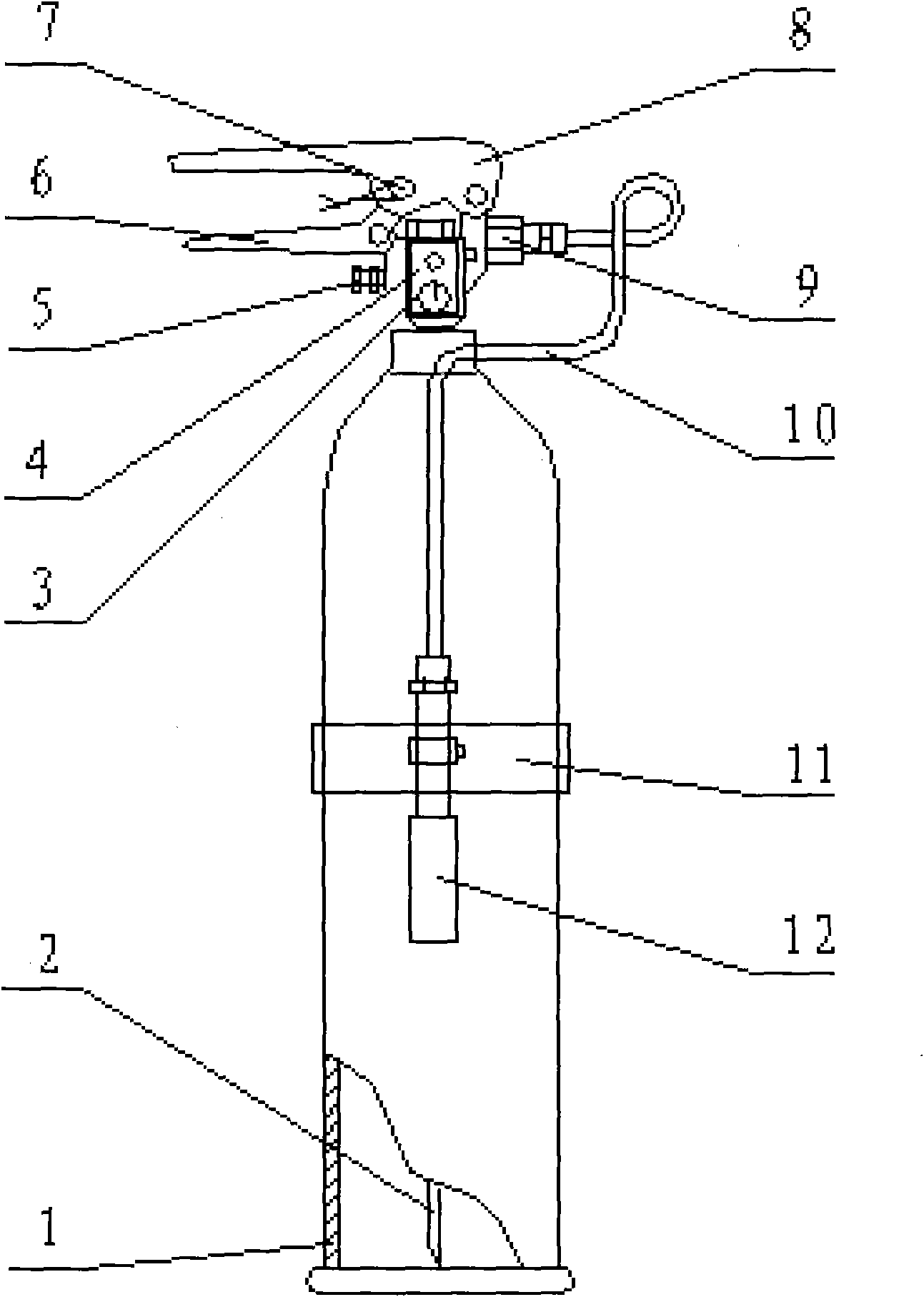

[0036] The fire extinguisher designed in this embodiment includes a pressure storage cylinder 1 and a siphon tube 2 provided therein. The mouth of the pressure storage cylinder 1 is connected to the start valve 4 with a tapered thread, and the start valve 4 communicates with the siphon tube 2. Handle 8, press the handle 8 down to open the starting valve 4, set the safety plug 7 on the starting valve 4, set the pressure gauge 3 in the middle of the starting valve 4, set the safety plug 5 and the handle 6 on one side of the starting valve 4, and set the safety plug 5 and the handle 6 on the other side of the starting valve 4 A hose interface 9 is arranged on the side, and a pressure-resistant hose 10 is connected between the hose interface 9 and the spray head 12. The spray head 12 is placed on the entrainment belt 11, and the entrainment belt 11 is installed on the bottle body of the pressure storage cylinder 1 (see figure 1 ).

[0037] The spool diameter of the starting valve ...

Embodiment 2

[0041] The structure of the fire extinguisher designed in this embodiment is basically the same as in Embodiment 1. The distinguishing feature is that the structure of the spray head 12 is different. The central through hole between the nozzle 13 and the mixing chamber 16 of the spray head 12 of this embodiment does not have the swirl plate 14 and the flow splitter 15 which are inlaid and installed in sequence, but replace the front sealing gasket 25, and the rest of the structure is the same as Embodiment 1 (see Figure 9 ). The sealing gasket 25 is made of rubber, with a diameter of 10 mm and a thickness of 2 mm. The fire extinguishing agent used in the fire extinguisher of this embodiment is water and carbon dioxide gas. The steel cylinder 1 is made of ordinary pressure-resistant steel. The inner wall of the steel cylinder 1 is coated with an anti-corrosion coating. The total volume in the bottle is about 8 liters. 4 / 5, under the pressure of 3MPa, dissolve carbon dioxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com