Switch cabinet with automatic fire extinguishing function

An automatic fire extinguishing and switchgear technology, applied in the field of switchgear, can solve the problems of switchgear fire, large weight and volume, safety accidents, etc., to achieve the effect of convenient maintenance and replacement, avoiding fire expansion, and increasing fire extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

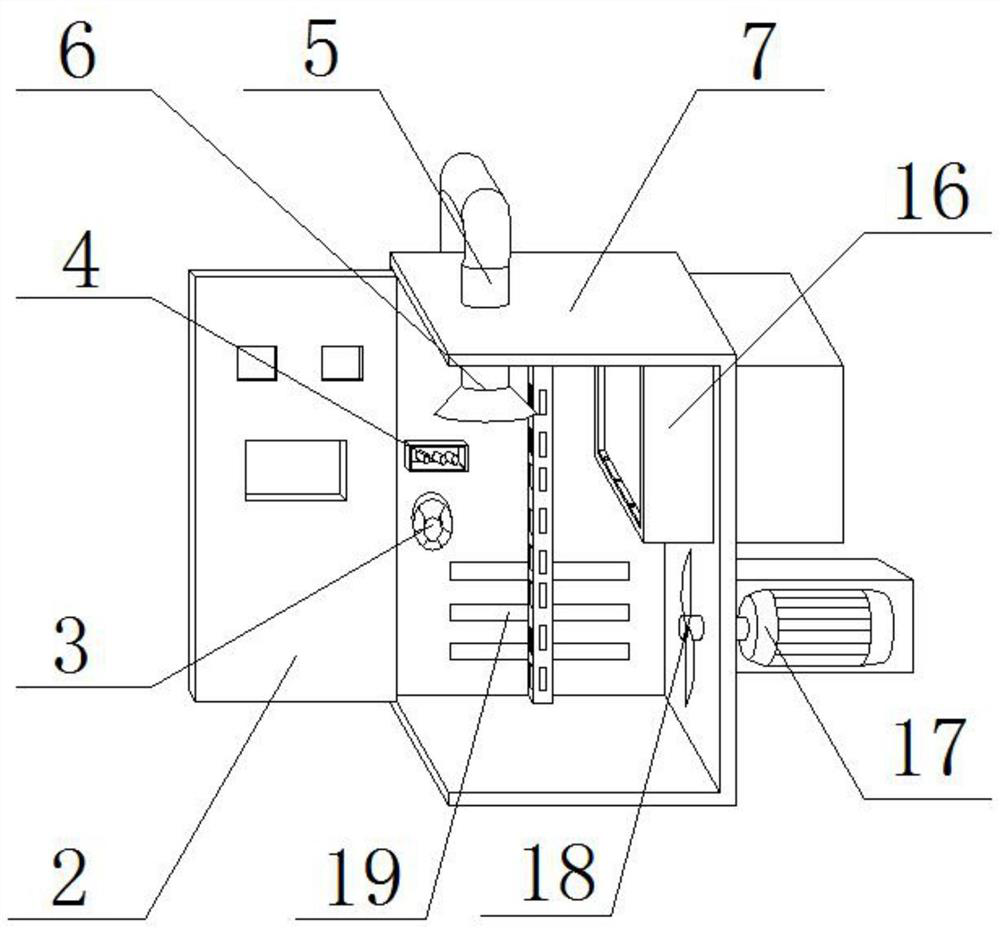

[0032] see Figure 1-Figure 7 , the present invention provides a switchgear with automatic fire extinguishing function, comprising a base 1, a cabinet body 7 is fixedly installed above the base 1, a cabinet door 2 is movably installed on the left end of the cabinet body 7, and smoke is fixedly installed inside the cabinet body 7 Sensor 3, a temperature sensor 4 is fixedly installed above the smoke sensor 3, a nozzle 6 is fixedly installed above the temperature sensor 4, a connecting pipe 5 is fixedly installed above the nozzle 6, and a bolt 8 is movably installed on the right side of the connecting pipe 5. The right side of the body 7 is movably equipped with a movable plate 9, the lower end of the movable plate 9 is movably installed with a wind deflector 10, the upper surface of the base 1 is provided with a chute 11, and the bottom of the base 1 is movably equipped with wheels 12, and the cabinet body 7 A solenoid valve 13 is fixedly installed on the left side, a starter bo...

Embodiment 2

[0036] like Figure 1-5 As shown, the difference between this embodiment and Embodiment 1 is that the connecting pipe 5 runs through the upper surface of the cabinet body 7, one end of the connecting pipe 5 is connected with the nozzle 6, and the other end of the connecting pipe 5 is connected with the gas storage The bottles 14 are connected, the smoke sensor 3 and the temperature sensor 4 are connected with the electromagnetic valve 13 by wires, the dry powder box 16 runs through the rear surface of the cabinet 7, the sealing plate 20 and the dry powder box 16 are connected by a rotating shaft, and the expansion metal One end of the block 23 is fixedly installed in the inside of the fixing hole 22, and the other end of the expansion metal block 23 is fixedly installed in the inside of the fixing box 24, and the fixing pin 21 and the dry powder box 16 are fixedly connected through the fixing hole 22; the ventilation holes 19 are provided in total There are six groups, wherein...

Embodiment 3

[0039] like figure 1 and Figure 7 As shown, the difference between this embodiment and Embodiments 1 and 2 is that there are three groups of fixing grooves 32, wherein two groups of fixing grooves 32 are respectively provided at the upper and lower ends of the right surface of the cabinet body 7, and the other group Fixed groove 32 is offered at the right surface rear end of cabinet body 7, and fixed bar 33 is provided with three groups altogether, wherein two groups of fixed bars 33 are fixedly installed on the upper and lower ends of the left surface of movable plate 9, and another group of fixed bars 33 are fixedly installed on movable plate 9. On the rear end of the left surface of the plate 9, several groups of threaded holes 31 are arranged, and several groups of threaded holes 31 are evenly opened on the fixing groove 32 and the fixing bar 33, and a group of bolts 8 are movably installed on each group of threaded holes 31, and the cabinet body 7 and movable plate 9 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com