Fool type self-learning motor soft on-off control device

A start-stop control, self-learning technology, applied in motor generator control, motor generator/starter, control system, etc., can solve problems such as unfavorable customer management and maintenance, high technical support personnel overhead, and large power grid impact, etc. Achieve the effect of reducing customer management and maintenance costs, unmanned operation, and foolish use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

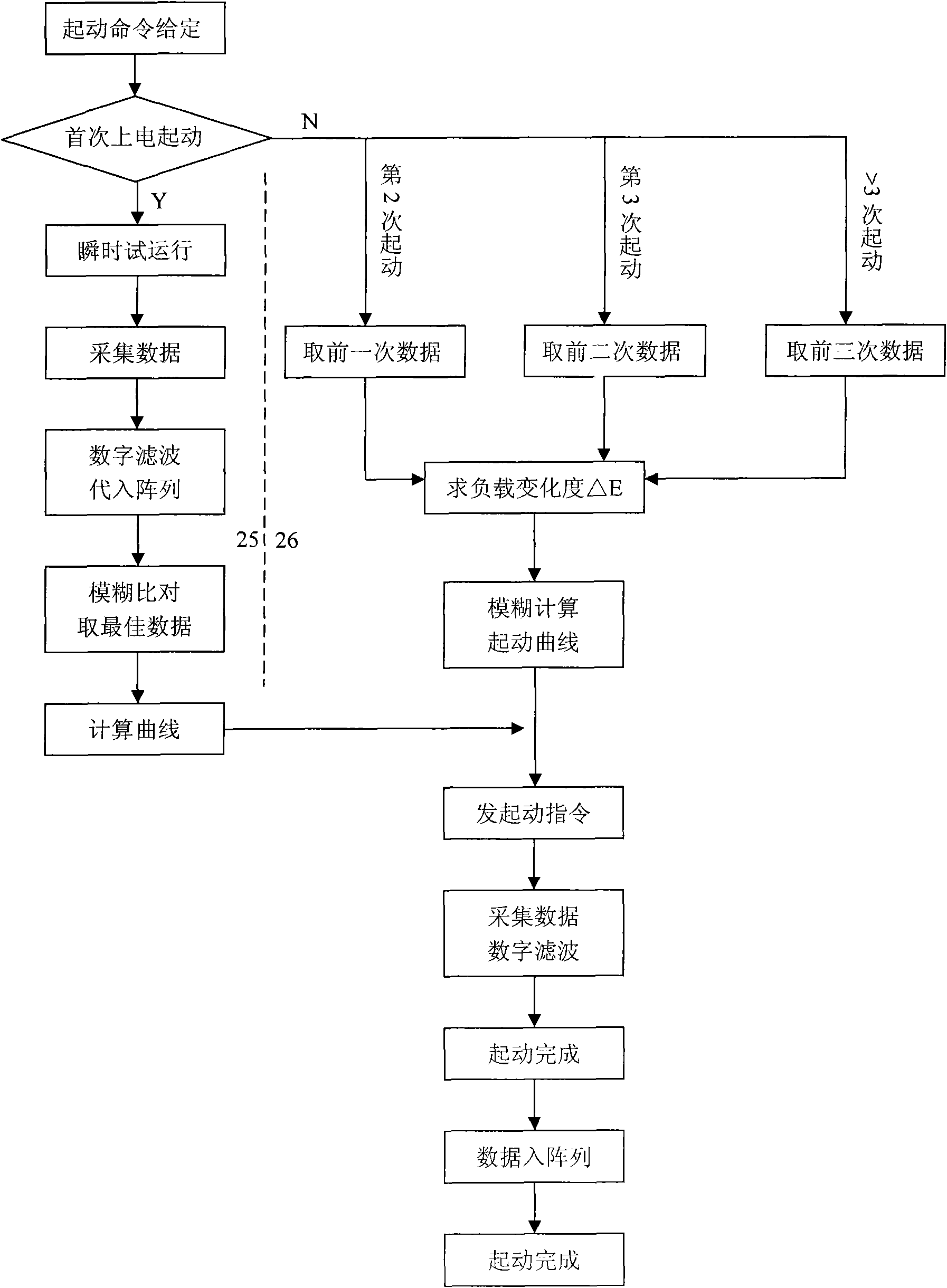

[0018] Such as figure 1 As shown, the device of the present invention is connected in series between the power supply 1 and the motor 2, adopts three reverse-parallel semiconductor controllable rectifiers SCRs 3 as power components, and a high-speed central processing unit 4 controls the acquisition circuit to acquire motor parameters, including current acquisition 5, Voltage collection 6, phase sequence collection 7, synchronous signal collection 8 and power factor collection 9, etc., central processing unit 4 processes and analyzes according to the data sampled back, applies the phase shift technology of SCRs 3, controls the conduction angle of SCRs 3, makes The voltage added to the motor 2 gradually reaches the full voltage according to the calculation rule, and the 3 groups of different color LEDs in the display part 12 indicate the operating status of the system in real time, such as soft start, soft stop, fault alarm and other information, Make the system status clear at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com