Ultracrystalline transformer core manufacturing method and special mould therefor

A technology for transformer iron cores and manufacturing methods, which is applied to the manufacture of inductors/transformers/magnets, transformer/inductor cores, electrical components, etc., and can solve deformation, large power loss, and uneven thickness of ultrafine-crystalline iron core embryos And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 The making of ultramicrocrystalline transformer iron core

[0032] The specifications of the ultra-microcrystalline iron core are as follows:

[0033] A(mm)

B(mm)

C(mm)

D(mm)

Effective cross-sectional area

(cm) 2

(cm)

Core quality

(kg)

270

170

60

60

36

84.57

20.3

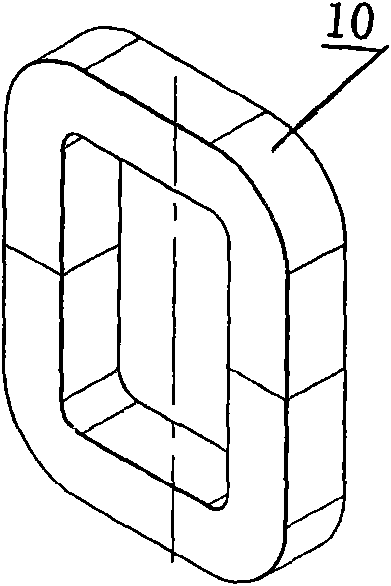

[0034] A, B, C, and D in the table represent the size values of each part of the iron core, and the corresponding iron core parts refer to figure 1 (1), figure 1 (2).

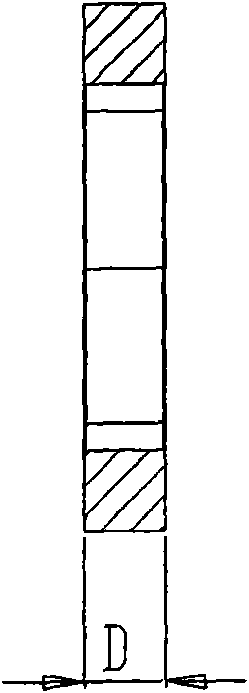

[0035] The production process is as follows: First, the thick side and the thin side of the thin sheet-shaped ultrafine crystal strips are overlapped in pairs, and a pair (or multiple pairs of overlapping) ultrafine crystal strips are placed on top of each other. figure 2 The outer wall of the circular mold shown is overlapped and wound to the desired thickness, then the connecting rod 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com