Soft magnetic amorphous alloy wire and preparation method thereof

A technology of amorphous alloy and alloy wire, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of increasing the cost of alloy wire, low cost, controllability limit of supercooling speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

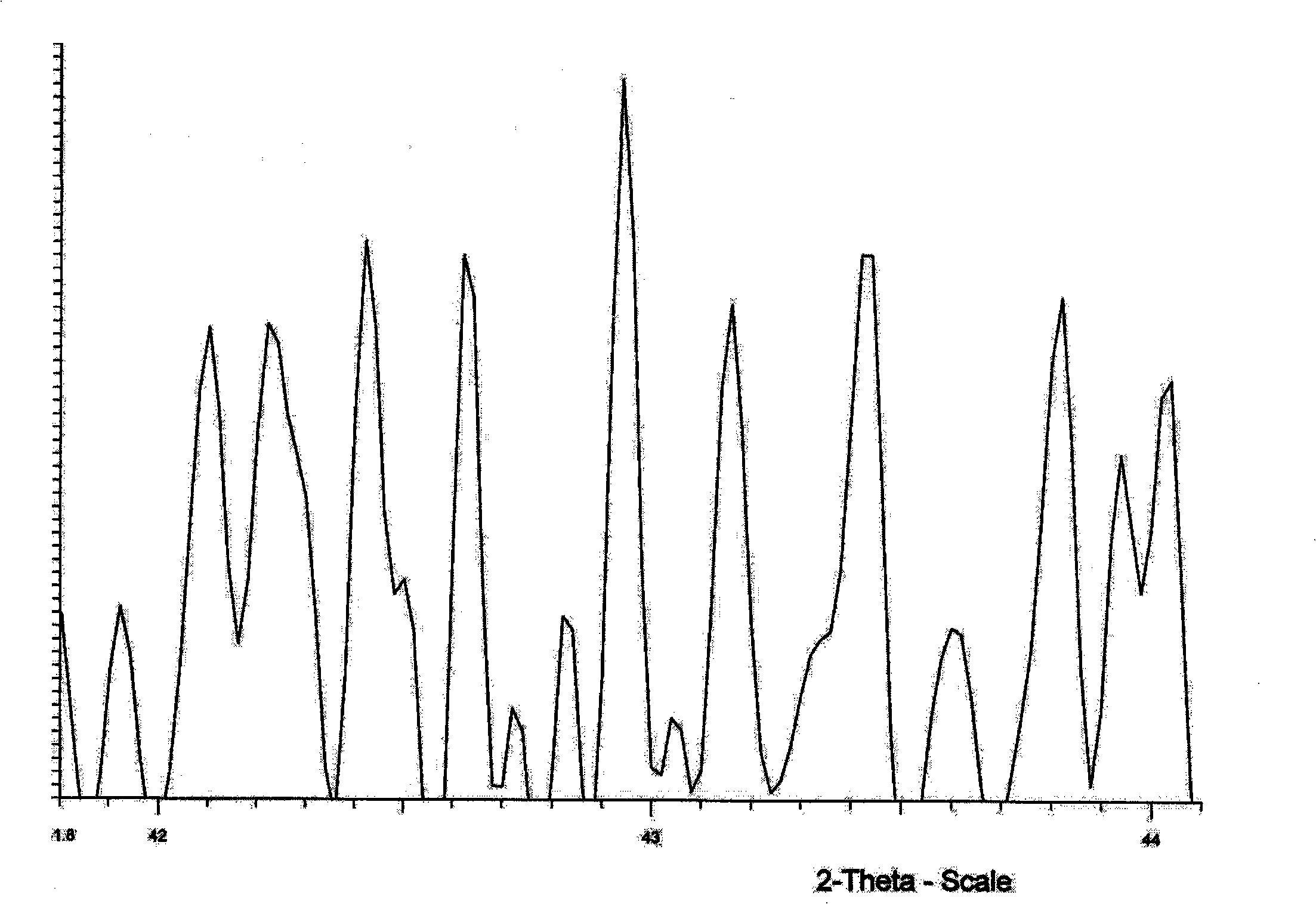

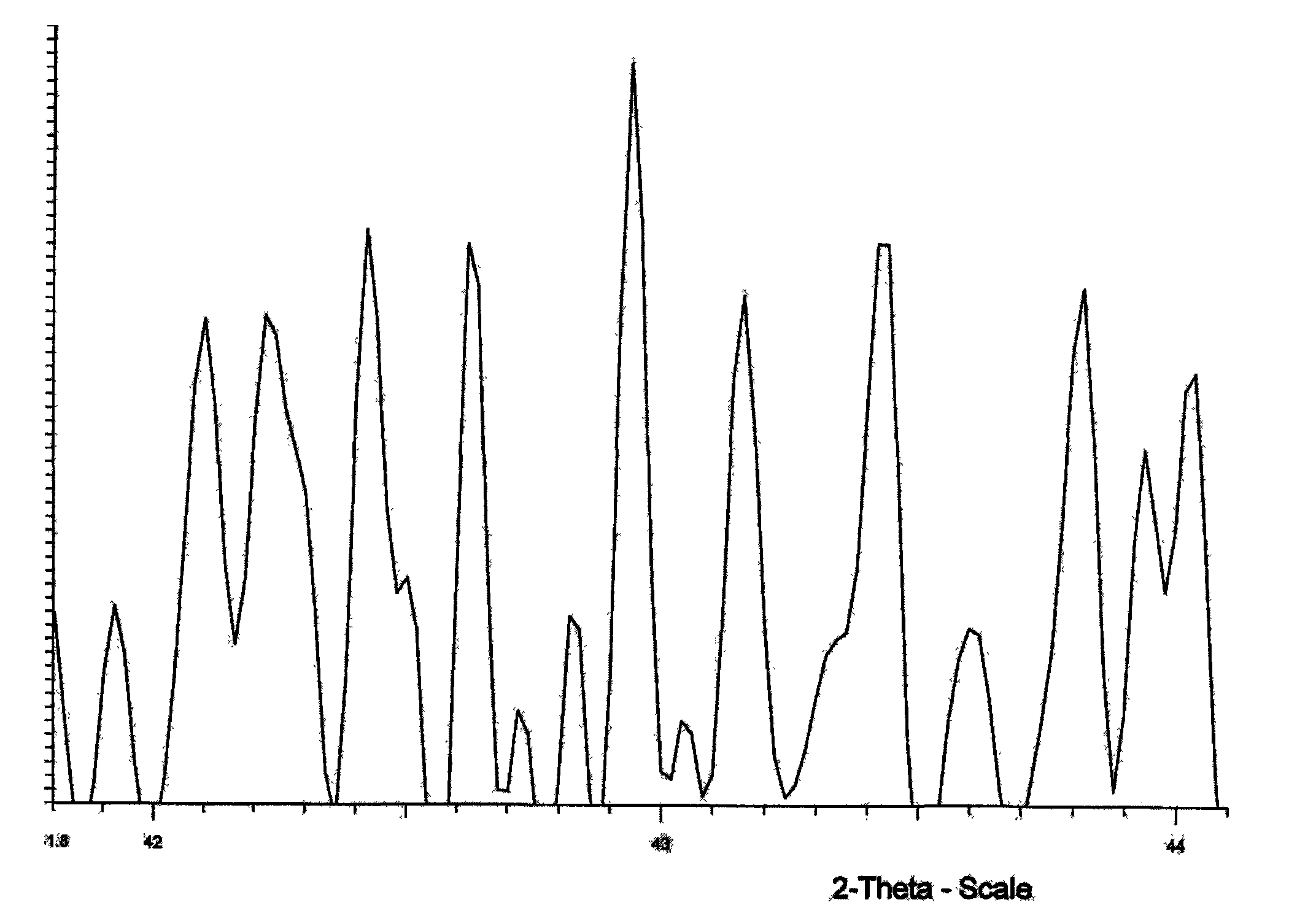

Image

Examples

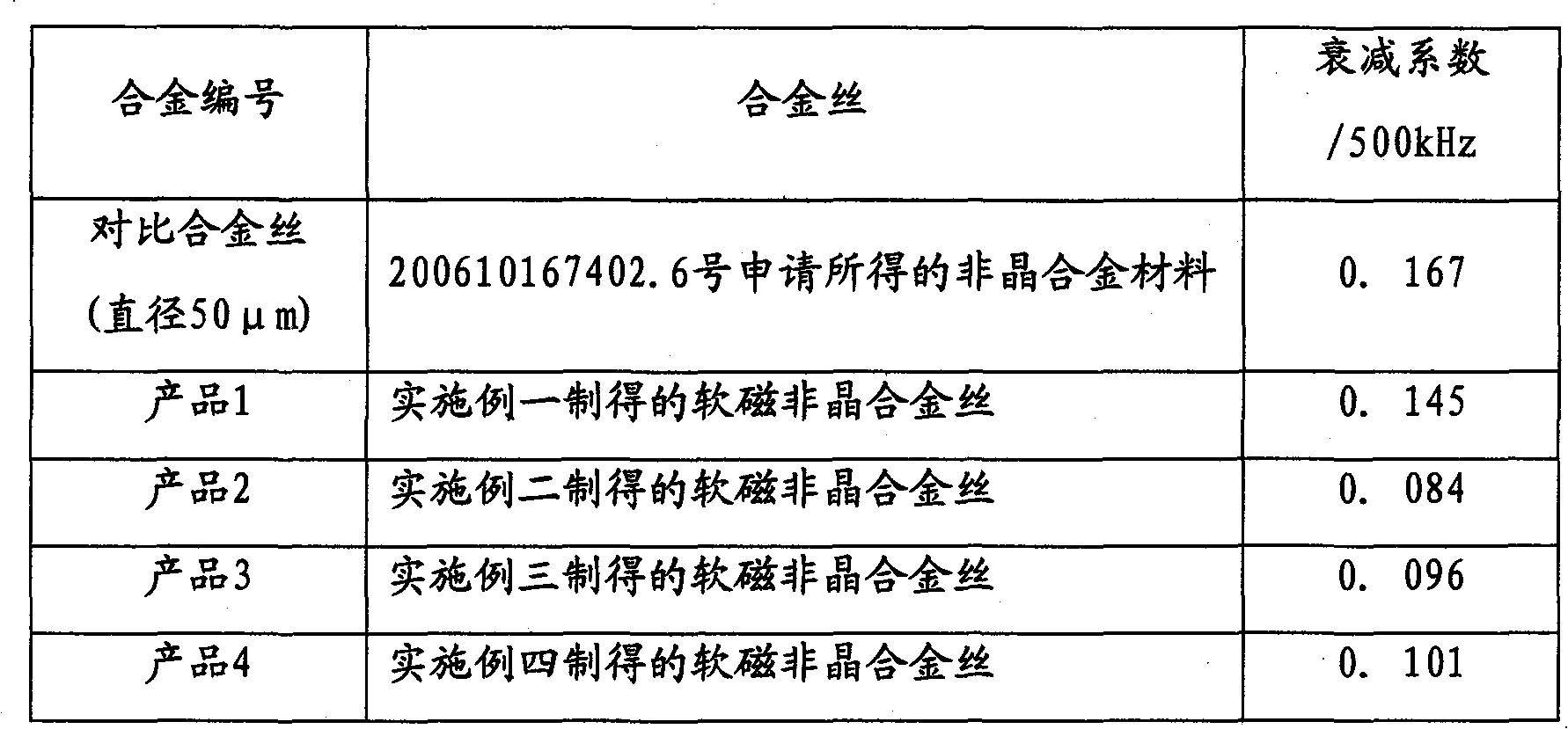

Embodiment 1

[0019] The preparation method of soft magnetic amorphous alloy wire of the present invention:

[0020] The content by weight percentage is: Zr 2%, Cu 2%, Pr 0.05%, Ce 0.01%, B 4%, Al 3%, P 2%, Si 1%, the rest is Fe for batching, Fe, Al in raw materials , Cu, B, Pr, Ce, Si, Zr have a purity greater than 99.9%, P is added in the form of an iron-phosphorus master alloy, and the weight percentage of P in the iron-phosphorus master alloy is 18%; the raw materials are put into a vacuum induction furnace Melting, the melting temperature is 1600°C to obtain the master alloy, and then put it into the remelting tubular crucible in the vacuum induction quenching furnace for remelting, the remelting temperature is 1500°C, and the top of the remelting tubular crucible is placed in the rapid quench At 2-4mm below the rim of the furnace runner, a refractory plunger that can form the bottom of the tubular crucible can be placed in the tubular crucible by controlling the up and down movement. ...

Embodiment 2

[0022] The preparation method of soft magnetic amorphous alloy wire of the present invention:

[0023] The content by weight percentage is: Zr 6%, Cu 4%, Pr 0.1%, Ce 0.05%, B 8%, Al 6%, P 5%, Si 3%, the rest is Fe for batching, and its preparation process is the same as the implementation example one.

Embodiment 3

[0025] The preparation method of soft magnetic amorphous alloy wire of the present invention:

[0026] The content by weight percentage is: Zr 3%, Cu 3%, Pr 0.1%, Ce 0.01%, B 4%, Al 4%, P 4%, Si 2%, the rest is Fe for batching, and its preparation process is the same as the implementation example one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com