Rearview mirror mask and preparation process thereof

A technology of rear-view mirror and mask, applied in the field of auto parts and preparation technology, can solve the problem of gap between lampshade and mask, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below through the embodiments and in conjunction with the accompanying drawings.

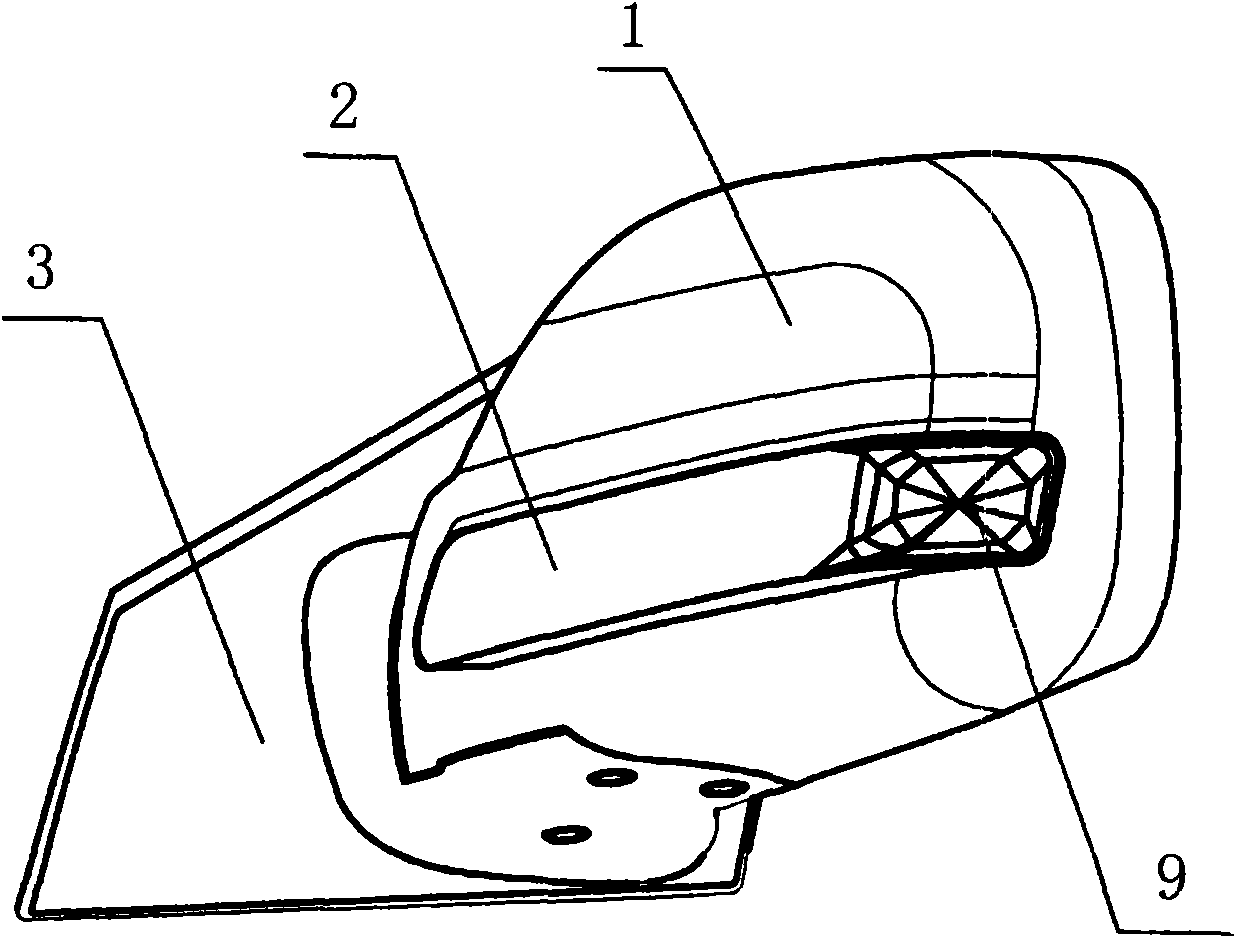

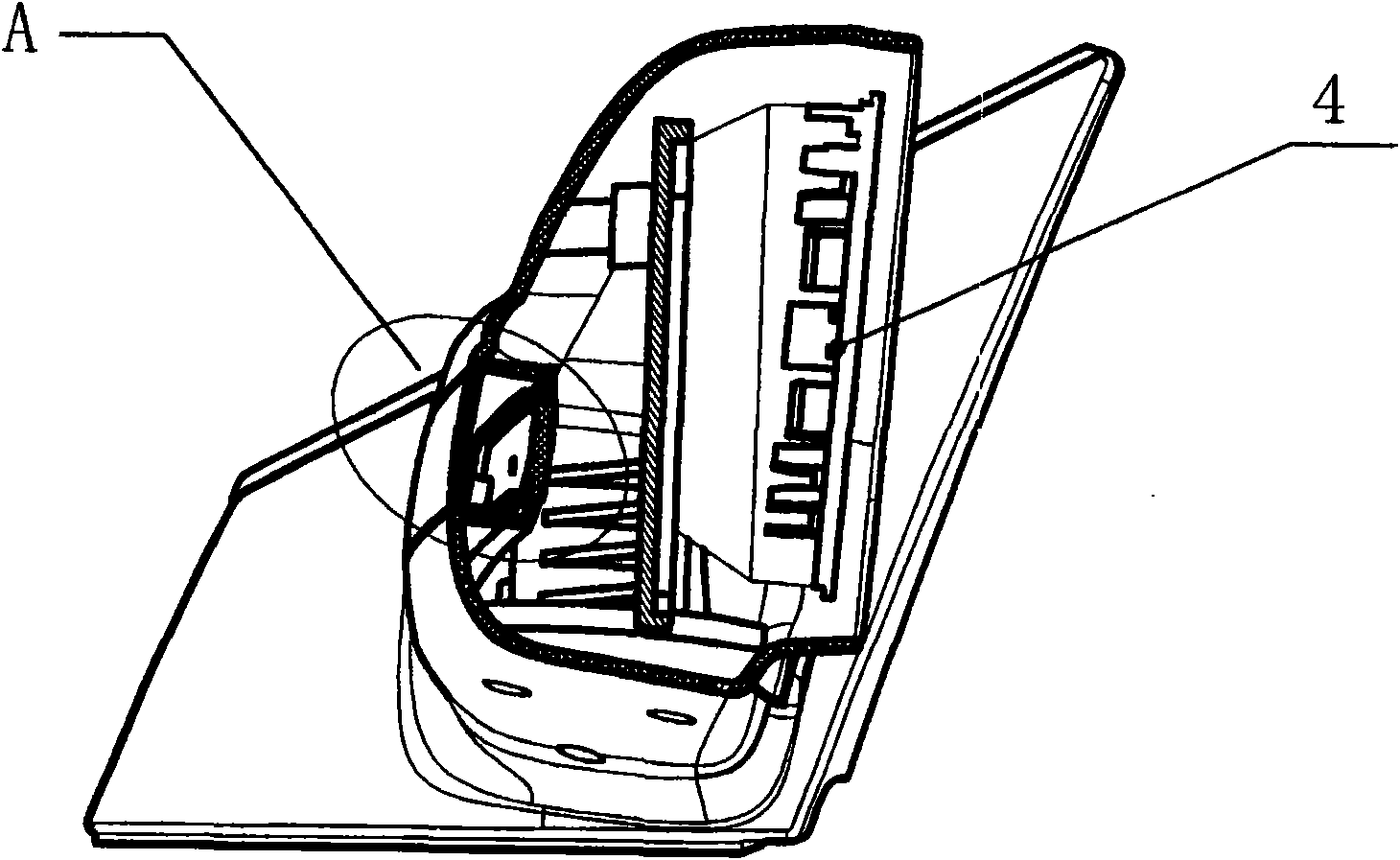

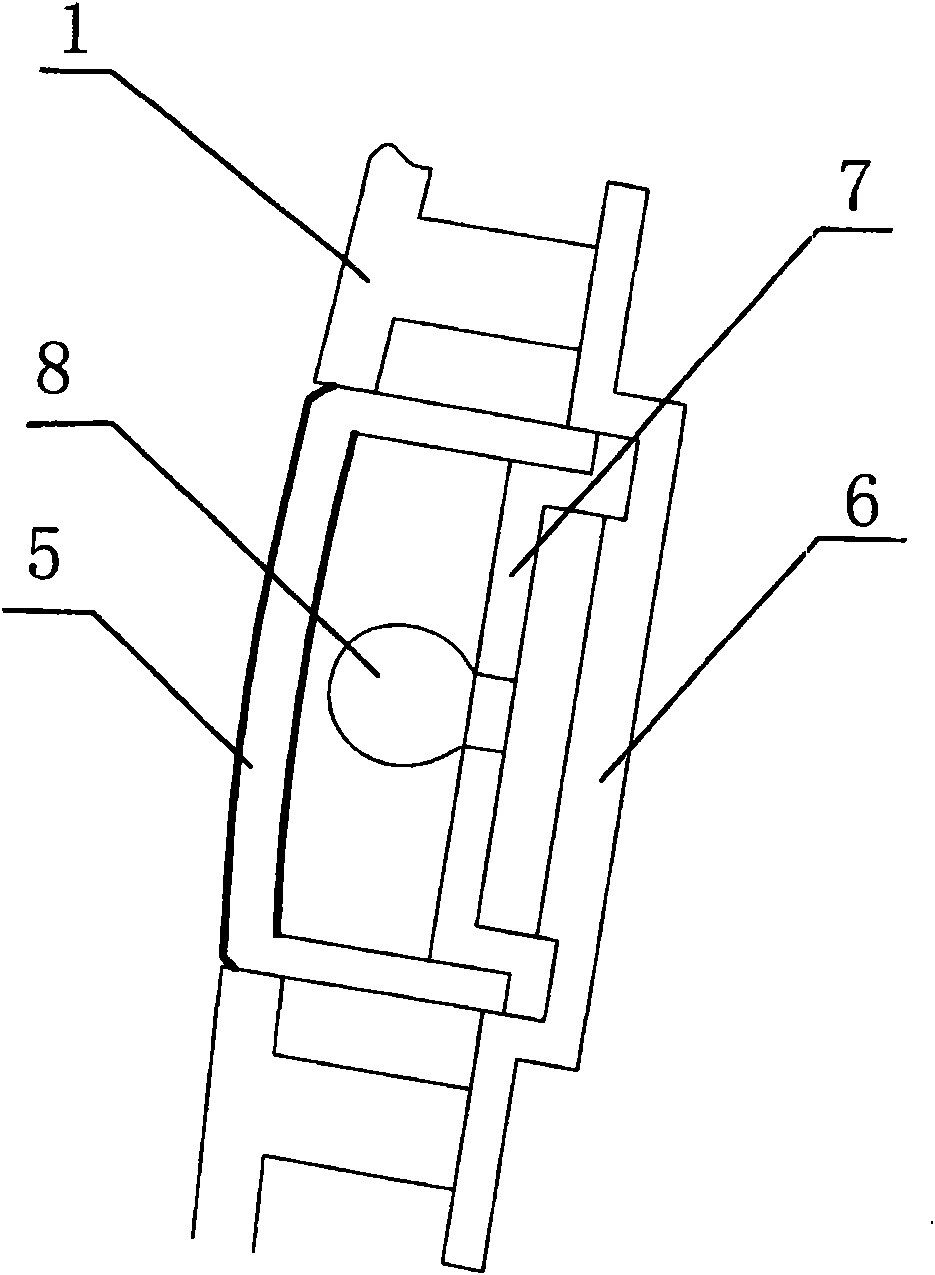

[0020] see Figure 4 and Figure 5 , the rearview mirror cover, including a face cover 1A and a transparent element that is convenient for the light emitted by the turn signal lamp 2 to pass through the face cover 1A. It is at the notch of the mask 1A and is sealed and integrated with the mask 1A.

[0021] Above-mentioned rearview mirror mask can be prepared by following two methods:

[0022] One method is to set two injection ports and two runners in the same mould, use ABS and PE two kinds of materials to injection mold the mask 1A and the lampshade 5A at the same time, after cooling, demold to obtain the rearview mirror mask.

[0023] Another method is to use PE to form the lampshade 5A first, then put the formed lampshade 5A as an insert into the mask injection molding mold, inject the mask 1A molding materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com