Method for producing plated diamond grinding wheel

A technology of electroplating diamond and production method, applied in metal processing equipment, grinding devices, grinding/polishing equipment, etc., can solve the problems of uneven nickel plating, shortened product life, difficult to satisfy customers, etc., to solve the problem of sand plating The effect of uneven circumference, wear reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

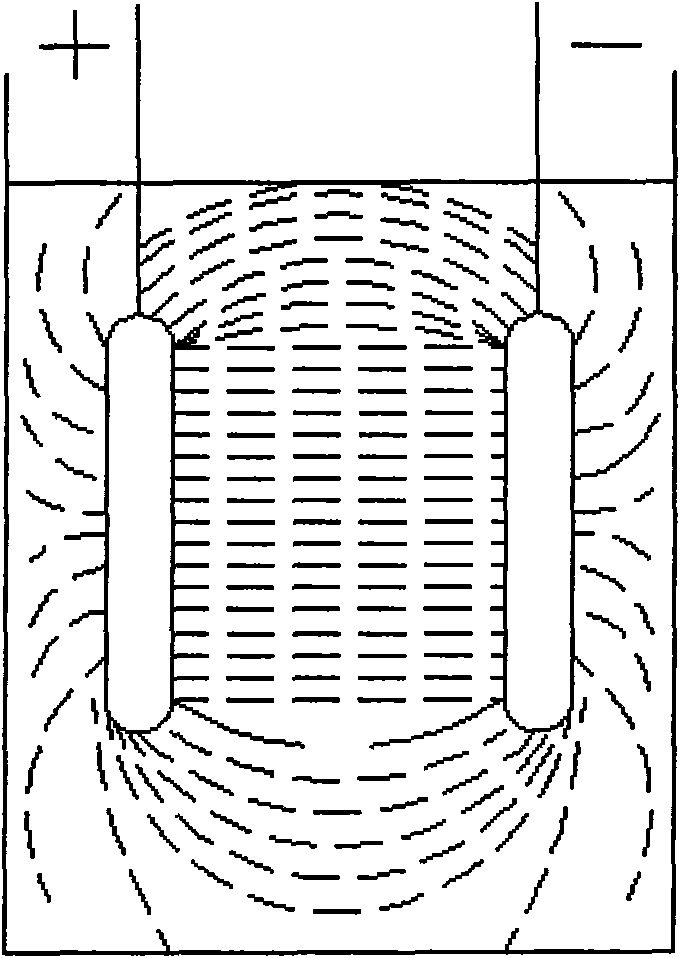

[0027] A production method of an electroplated diamond grinding wheel, specifically:

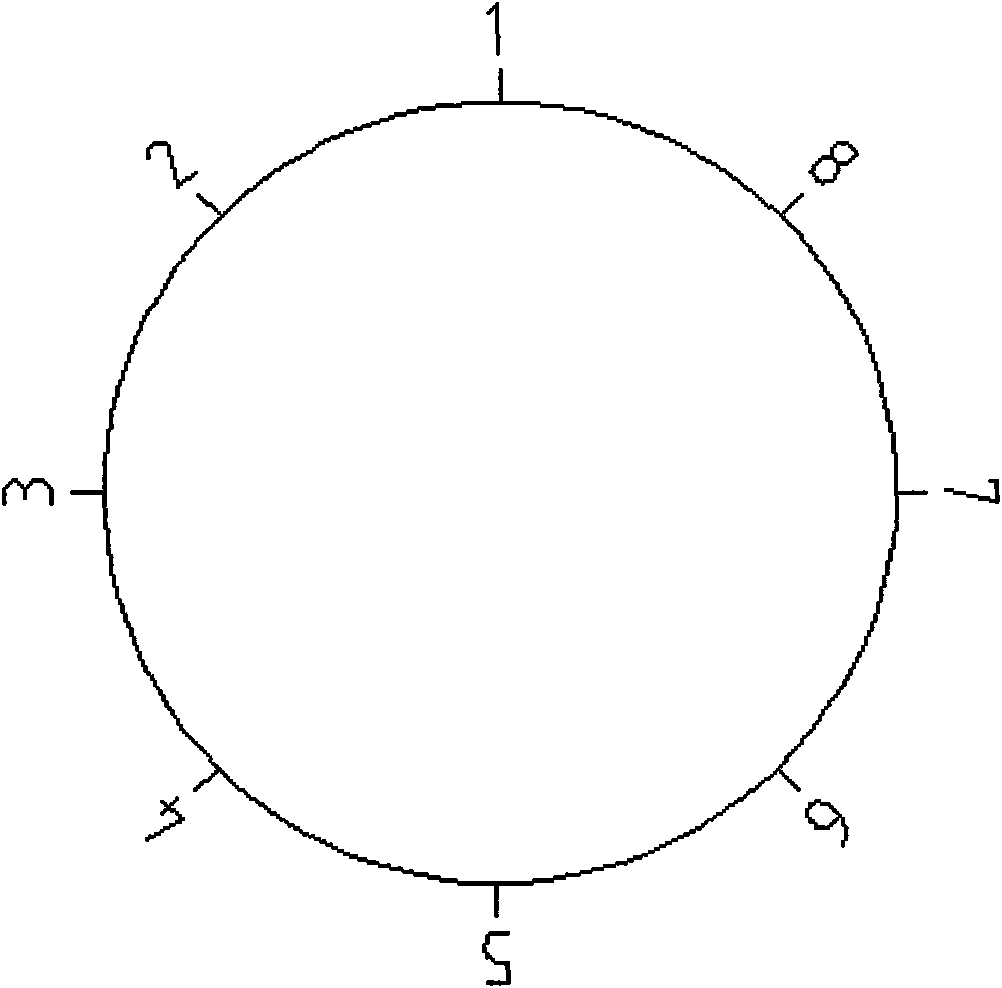

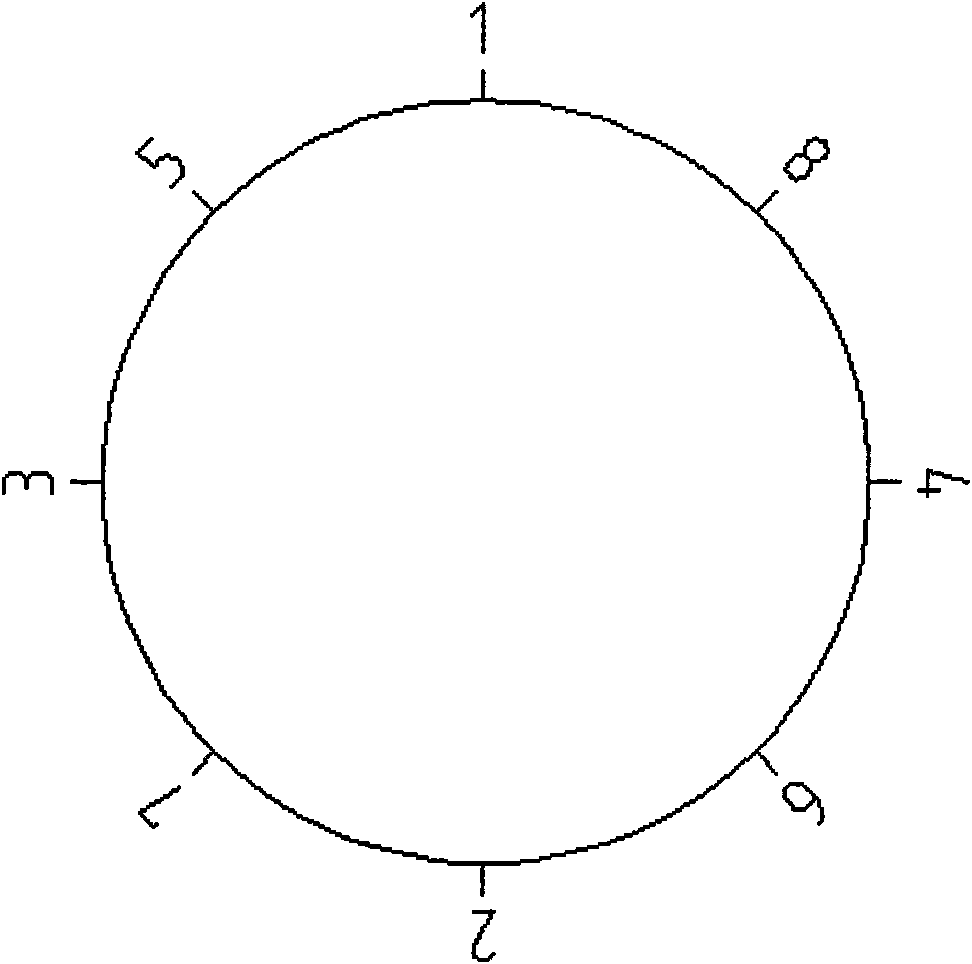

[0028] Grinding wheel substrate preparation: the substrate material is made into a grinding wheel shape, and the surface is roughened; steel is usually used to make the substrate, and the steel is processed by a CNC machine tool to meet the shape and surface roughness required by electroplating, and its surface roughness is detected on a projector. accuracy;

[0029] Pre-plating treatment: cleaning the grinding wheel substrate, dust removal, degreasing, polishing, clamping the fixture on the grinding wheel substrate, and then activating; in this embodiment, it is specifically: washing powder cleaning-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com