Automatic charging equipment for electric vehicle

An automatic charging device, electric vehicle technology, applied in battery circuit devices, electric vehicles, circuit devices, etc., can solve problems such as affecting the continuation mileage, irregular and reasonable vehicle parking, aging and damage of batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention designs a fast access parking charging device, which can not only enable the electric vehicle to park safely and reliably for quick access charging, but also enable the electric vehicle to park in a standardized and orderly manner in a community.

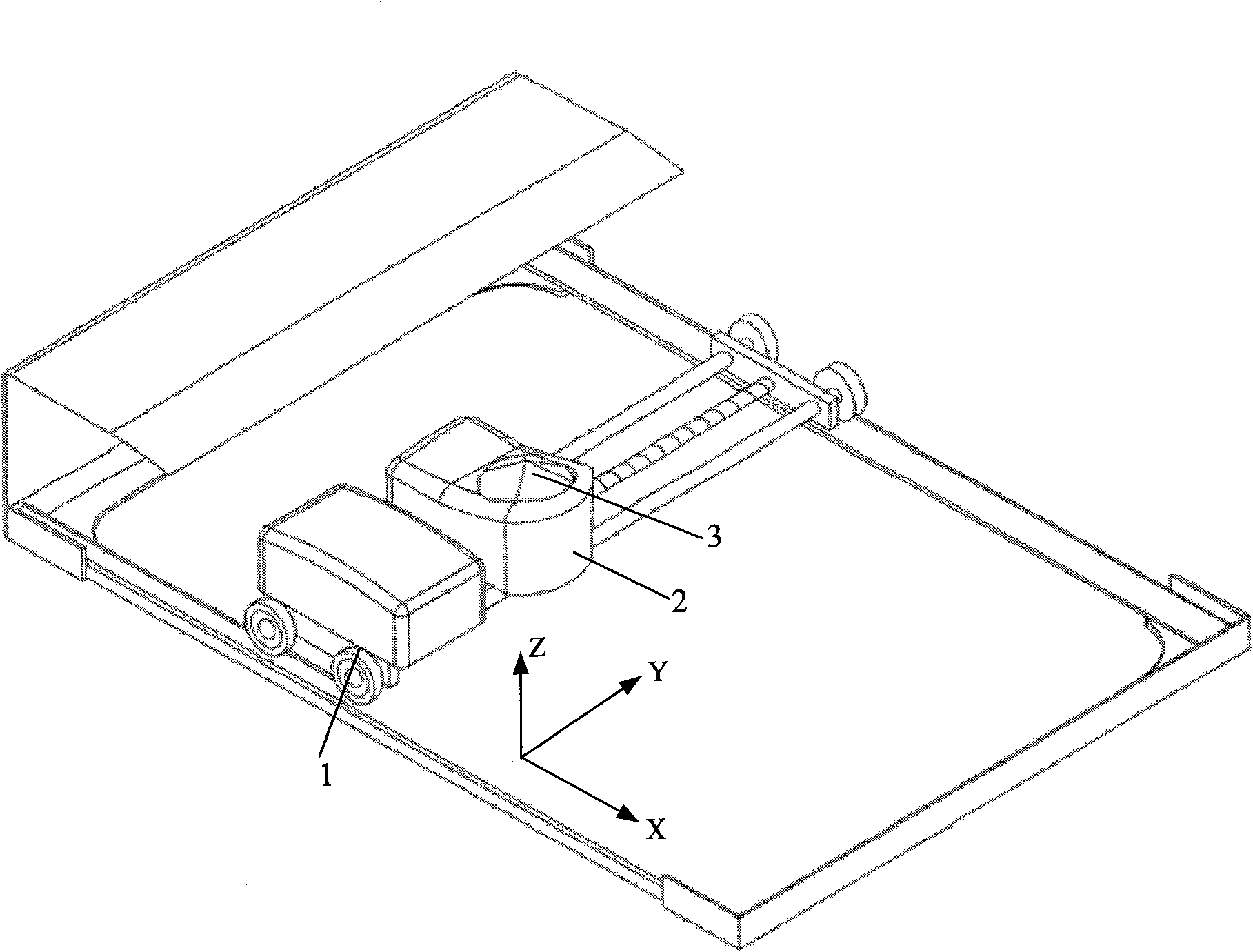

[0018] Such as figure 1 The electric vehicle automatic charging device shown has a mechanical part and an electrical control part, which are divided into a ground system and a vehicle system. The ground system includes mechanical and control devices and charging plugs in three degrees of freedom directions. The three degrees of freedom linkage transmission device includes X Axis transmission unit 1, Y-axis transmission unit 2 and Z-axis transmission unit 3, X-axis transmission unit 1 is perpendicular to Y-axis transmission unit 2, X-axis transmission unit 1 includes an X-axis pulley and a motor that controls the movement of the X-axis pulley, Y The axis transmission unit 2 includes a Y-axis slider and a motor fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com