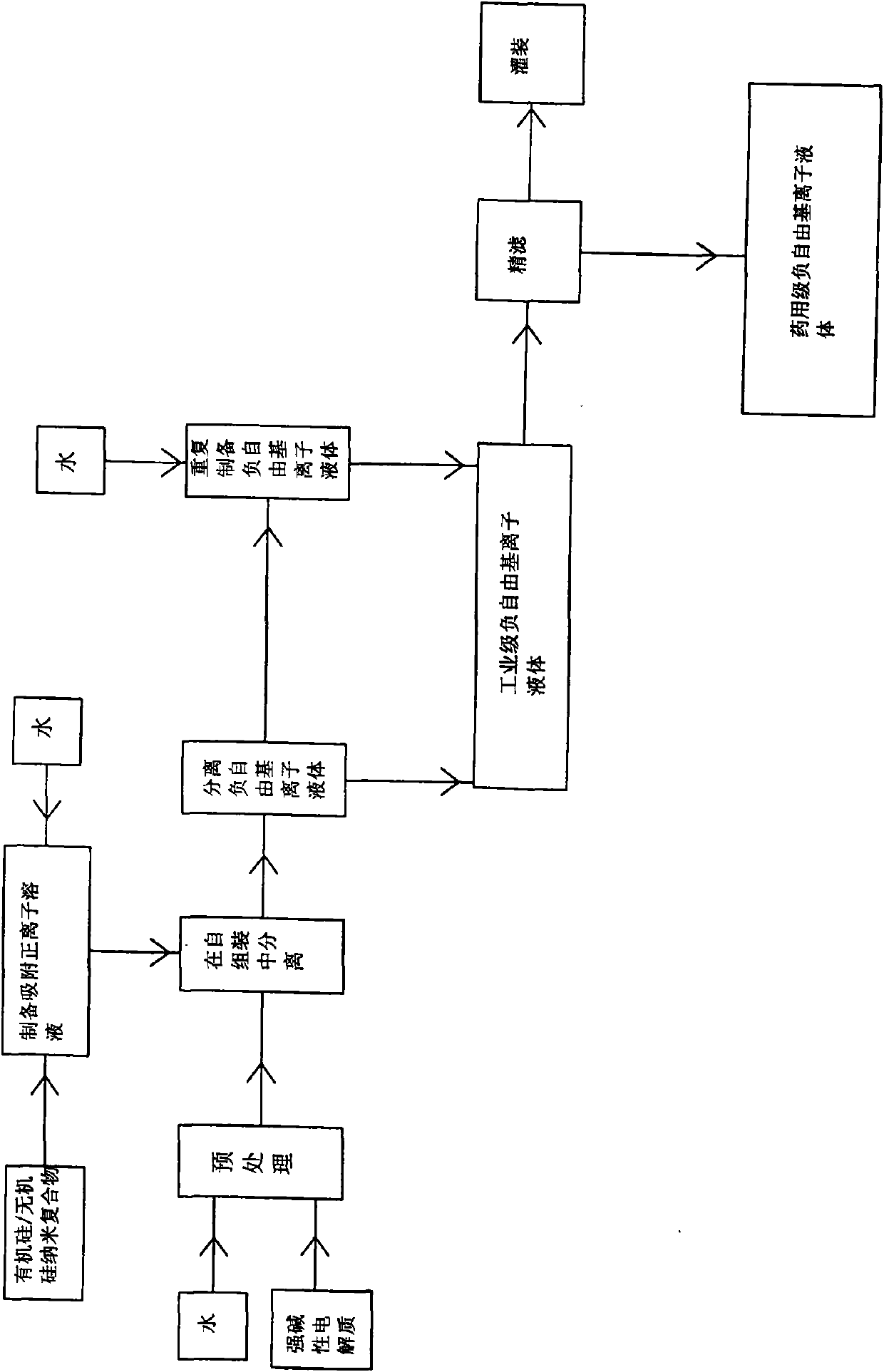

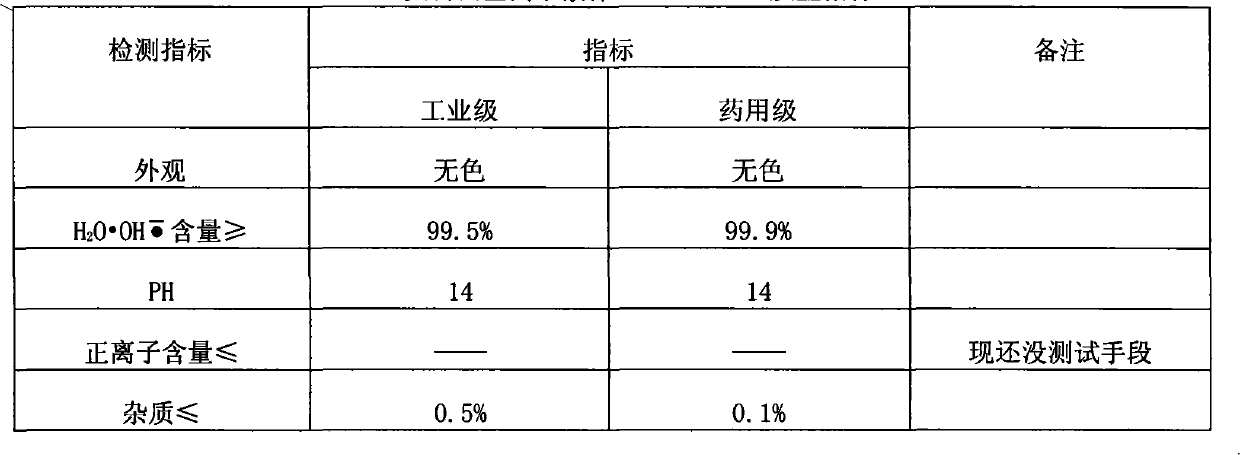

Negative radical ionic liquid and self-assembly ion isolation process

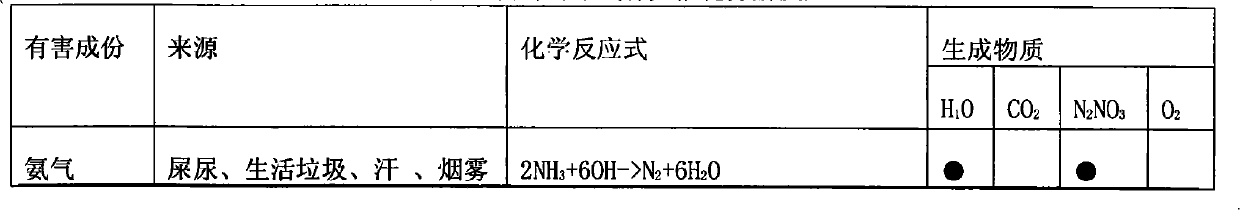

A technology of ionic liquid and ion separation, applied in nanoscience and field, can solve problems such as secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0121] Step 1: Strong Alkaline Electrolyte Pretreatment

[0122] Take 9.5Kg of calcium oxide, digest it with 200Kg of hot water at 80+-5°C, and then filter to remove the residue.

[0123] stand-by.

[0124] Step 2: Preparation of Adsorption Positive Ion Solution

[0125] Take 7Kg of organosilicon / inorganic silicon nanocomposite and 25Kg of deionized water, add them into the reaction kettle respectively, heat up to 90+-5°C, keep the temperature constant until it melts and dissolves, the conversion process is the same as Example 1.

[0126] Step 3: Self-Assembly and Dissociation in Repeated Ionization

[0127] Self-assembly is divided into two levels, one level is the self-assembly of negative radical ions; the other level is the self-assembly of positive ions. In the positive ion self-assembly process, the two levels of self-assembly are crossed and repeated. Through two levels of self-assembly, positive and negative ions are separated.

[0128] 1 Self-assembled negative r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com