Semiconductor device and method for manufacturing semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve the problems of wiring pattern lengthening, reducing wiring pattern resistance, etc., to prevent interface diffusion, excellent electrical characteristics, and high transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

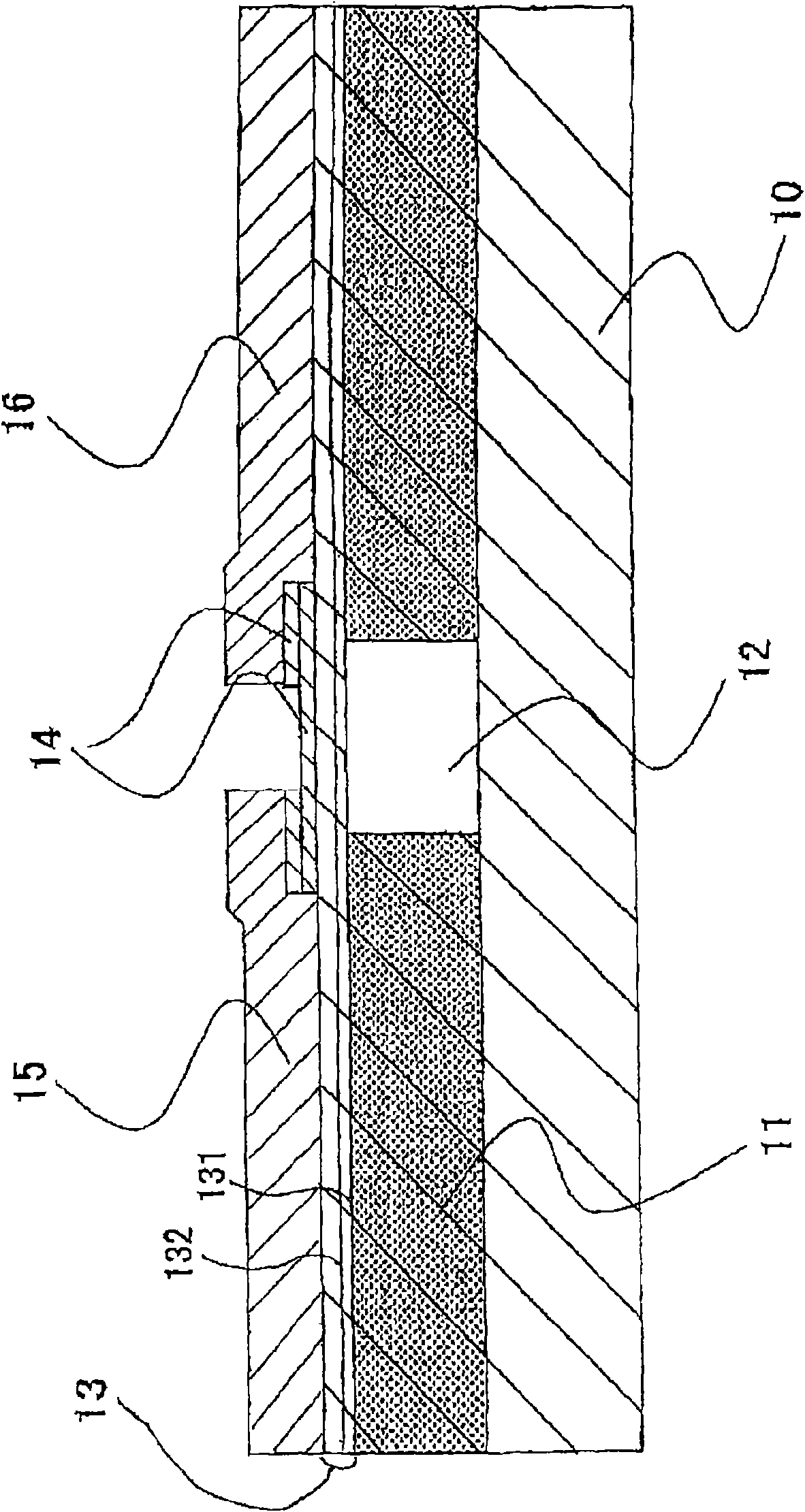

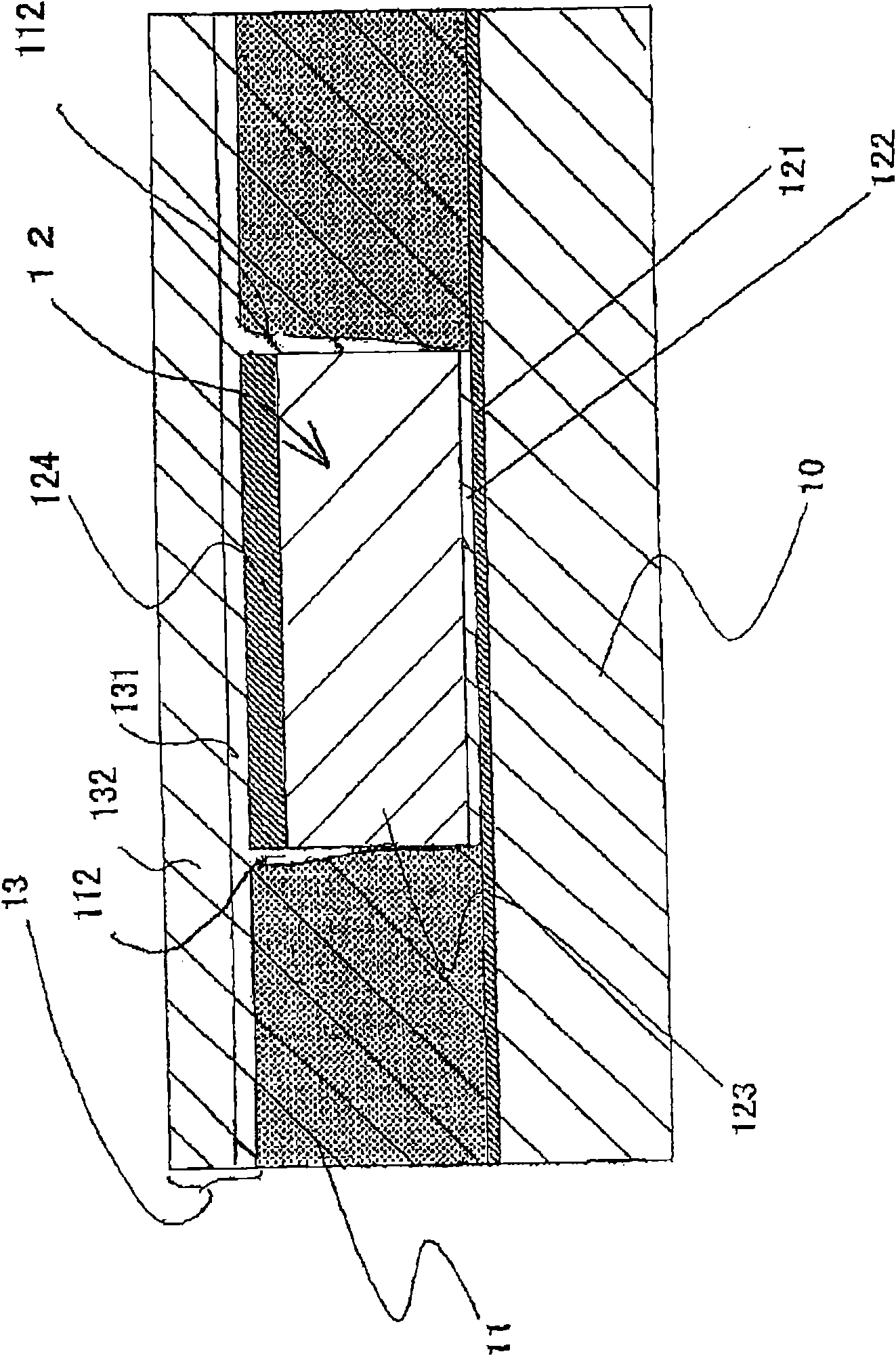

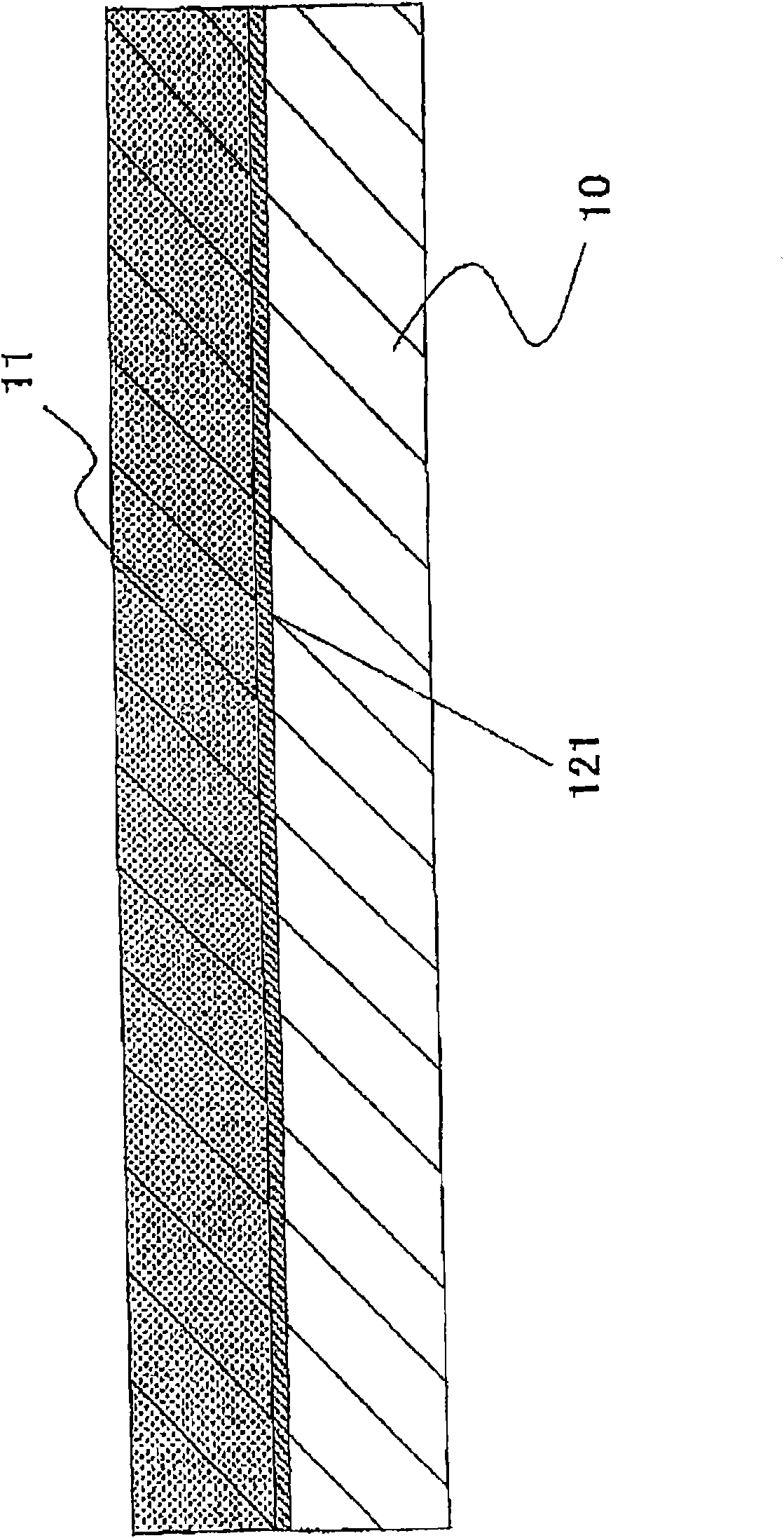

[0096] Next, the method of forming the thin film transistor according to the embodiment of the present invention described above will be described using the drawings. Figure 3 ~ Figure 7 It is a schematic diagram illustrating the manufacturing method of the thin film transistor of this embodiment in the order of steps. First, refer to image 3 , The glass substrate 10 is prepared as a substrate. This substrate is a large substrate capable of forming a large screen of 30 inches or more. The substrate was treated in a 0.5 vol% hydrofluoric acid aqueous solution for 10 seconds, and the surface was washed with pure water, thereby washing and removing surface contamination.

[0097] Then, sodium hydroxide was added to pure water to obtain an aqueous solution whose pH was controlled at 10, and the silane coupling agent, namely aminopropylethoxysilane, was dissolved at a concentration of 0.1% by volume in the aqueous solution to form such a silane coupling agent solution. The glass subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com