Water reducer produced by utilizing zirconium silica residues and production method thereof

A production method and technology of water reducing agent, applied in the field of building ceramic water reducing agent, can solve the problems of high cost, environmental pollution, insufficient whiteness and strength of the water reducing agent, achieve simple production method, reduce production cost and increase whiteness. The effect of degree and intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

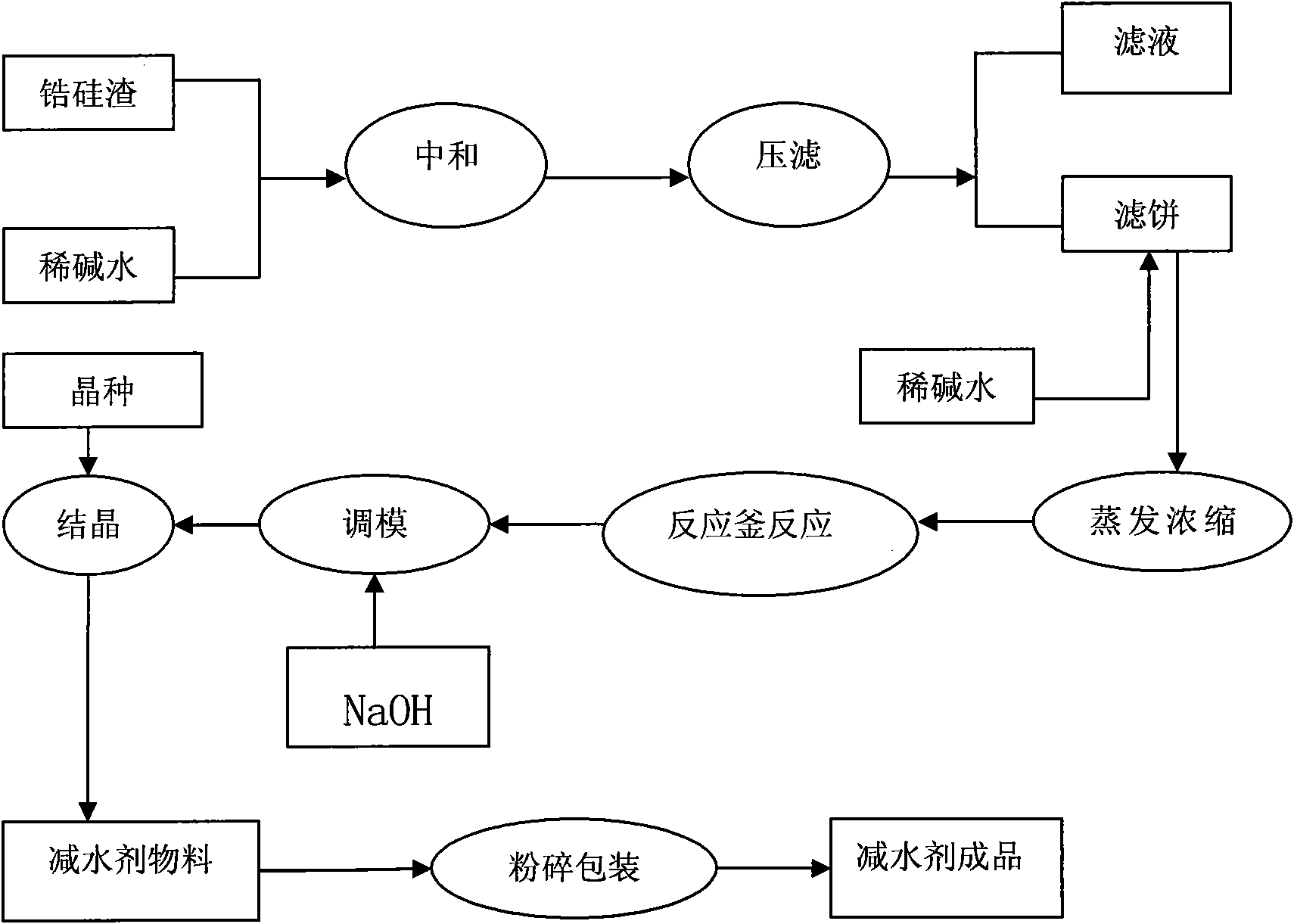

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: will contain 15% SiO 2 , 1% ZrO 2 Add 8% Na to 1000kg of silicon slag 2 O, 1% SiO 2 800kg of dilute alkaline water was neutralized to a pH value of 6, and filter cake was obtained by pressure filtration; 1500kg of dilute alkaline water was added to the filter cake for evaporation and concentration, and after evaporation and concentration, it was put into the reaction kettle, and the temperature was controlled at 120°C. After 5 hours of reaction, add NaOH90kg adjusts the modulus to 0.7, and when the solid content is 35%, the reaction solution is sent into the crystallizer, the temperature is controlled at 20°C, and the added 340kg contains 18% Na 2 O, 18% SiO 2 , 10% ZrO 2 , 54% crystal water of the water reducing agent crystal seeds are crystallized to obtain a water reducing agent, and the obtained water reducing agent material is crushed to obtain a finished product, which is packaged. The composition of the water reducing agent is: 18% Na 2 O, 18% ...

Embodiment 2

[0022] Embodiment 2: will contain 16% SiO 2 , 1.2% ZrO 2 Add 8.2% Na to the silicon slag 990kg 2 O, 1.2% SiO 2 785kg of dilute alkaline water was neutralized to a pH value of 6, and filter cake was obtained by pressure filtration; 1500kg of dilute alkaline water was added to the filter cake for evaporation and concentration, and after evaporation and concentration, it was put into the reactor, and the temperature was controlled at 120°C. After reacting for 5 hours, add NaOH81kg adjusts the modulus to 0.7, and when the solid content is 35%, the reaction solution is sent into the crystallizer, the temperature is controlled at 20°C, and the added 345kg contains 19% Na 2 O, 19.5% SiO 2 , 10.5% ZrO 2 , 51% crystal water of water-reducing agent crystal seeds are crystallized to obtain a water-reducing agent, and the obtained water-reducing agent material is crushed to obtain a finished product, which is packaged. The composition of the water-reducing agent is: 19% Na 2 O, 19.5%...

Embodiment 3

[0023] Embodiment 3: will contain 25% SiO 2 , 3% ZrO 2 Add 10% Na to 1000kg of silicon slag 2 O, 2% SiO 2 750kg of dilute alkaline water was neutralized to a pH value of 6, and filter cake was obtained by pressure filtration; 1200kg of dilute alkaline water was added to the filter cake for evaporation and concentration, and after evaporation and concentration, it was put into the reaction kettle, and the temperature was controlled at 120°C. After reacting for 5 hours, add NaOH80kg adjusts the modulus to 0.7, and when the solid content is 40%, the reaction solution is sent into the crystallizer, the temperature is controlled at 20°C, and the added 400kg contains 19% Na 2 O, 19% SiO 2 , 11% ZrO 2 , 51% crystal water of water-reducing agent crystal seeds are crystallized to obtain a water-reducing agent, and the obtained water-reducing agent material is crushed to obtain a finished product, which is packaged. The composition of the water-reducing agent is: 19% Na 2 O, 19% Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com