Digital control horizontal honing machine and honing method for realizing control of grinding force

A honing machine, horizontal technology, applied in the direction of honing machine tools, manufacturing tools, metal processing equipment, etc., can solve the problems of poor correction ability of non-circular pipe parts, can not realize the automatic control of grinding force, etc., to achieve convenient operation and intuitive screen display Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

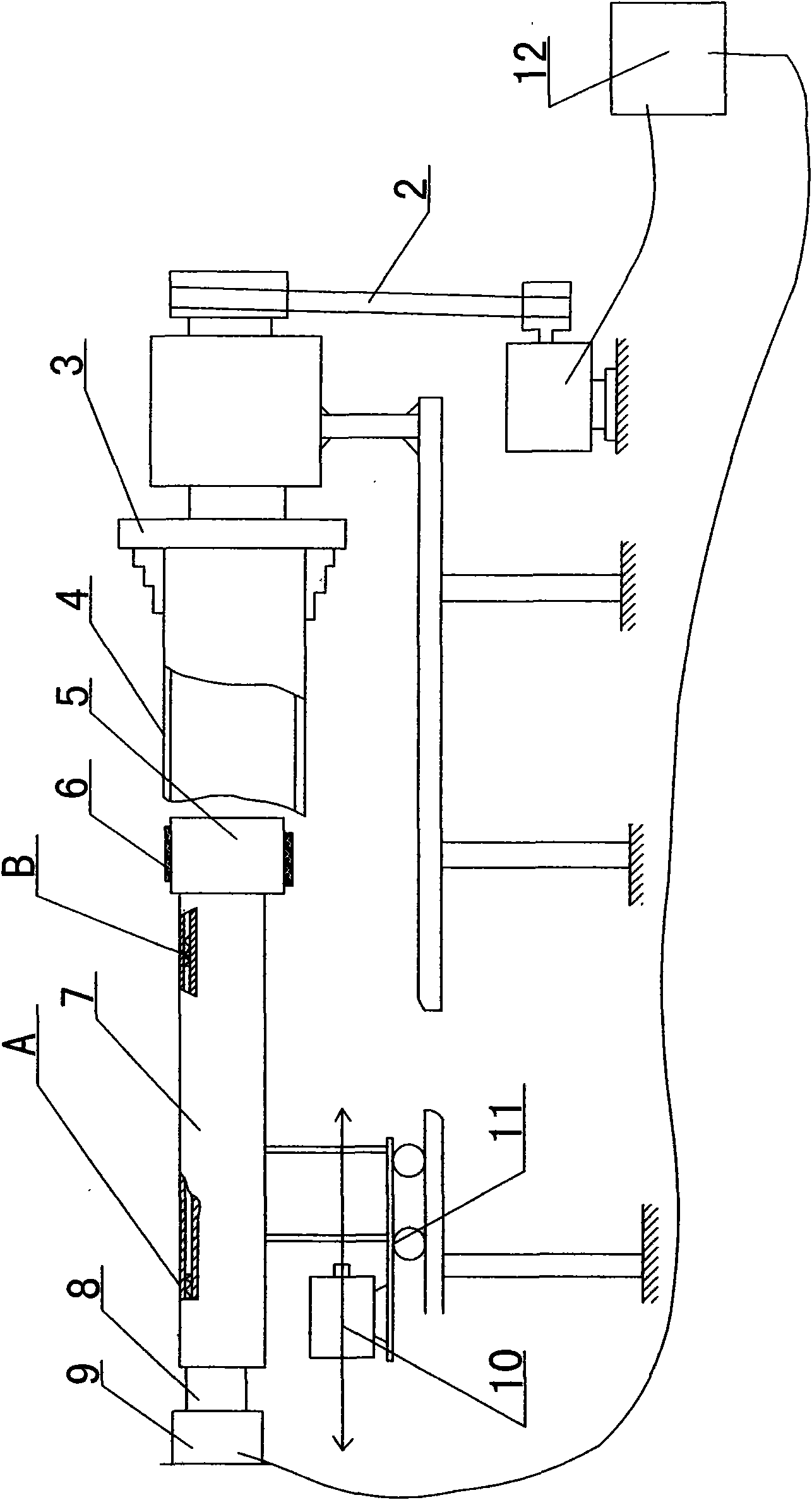

[0017] Markings in the figure 1, workpiece drive motor, 2, belt, 3, chuck, 4, workpiece, 5, honing head, 6, sand bar, 7, honing head grinding rod, 8, core rod, 9, core rod drive Device, 10. Grinding rod driving device, 11. Carriage trolley, 12. Calculation input control unit, lead screws at positions A and A, lead screws at positions B and B; 13. Sand rack, 14. Honing head core.

[0018] The honing machine can be divided into vertical type and horizontal type according to the clamping state of the workpiece. Due to the space limitation of the vertical honing machine, the horizontal honing machine is often used when grinding longer workpieces. According to the way of feeding sand bars, it is divided into those that use hydraulic feeding, called hydraulic feeding honing machines, and those that use mechanical feeding, called mechanical feeding honing machines, generally called honing machines. There are CNC hydraulic honing machines in China. As mentioned above, there is still ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com