Ultrasonic metal surface machining cutter

A technology for metal surface and processing tools, which is applied in the direction of metal processing equipment, manufacturing tools, and tools for lathes, etc., and can solve the problem that the surface of parts cannot be processed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

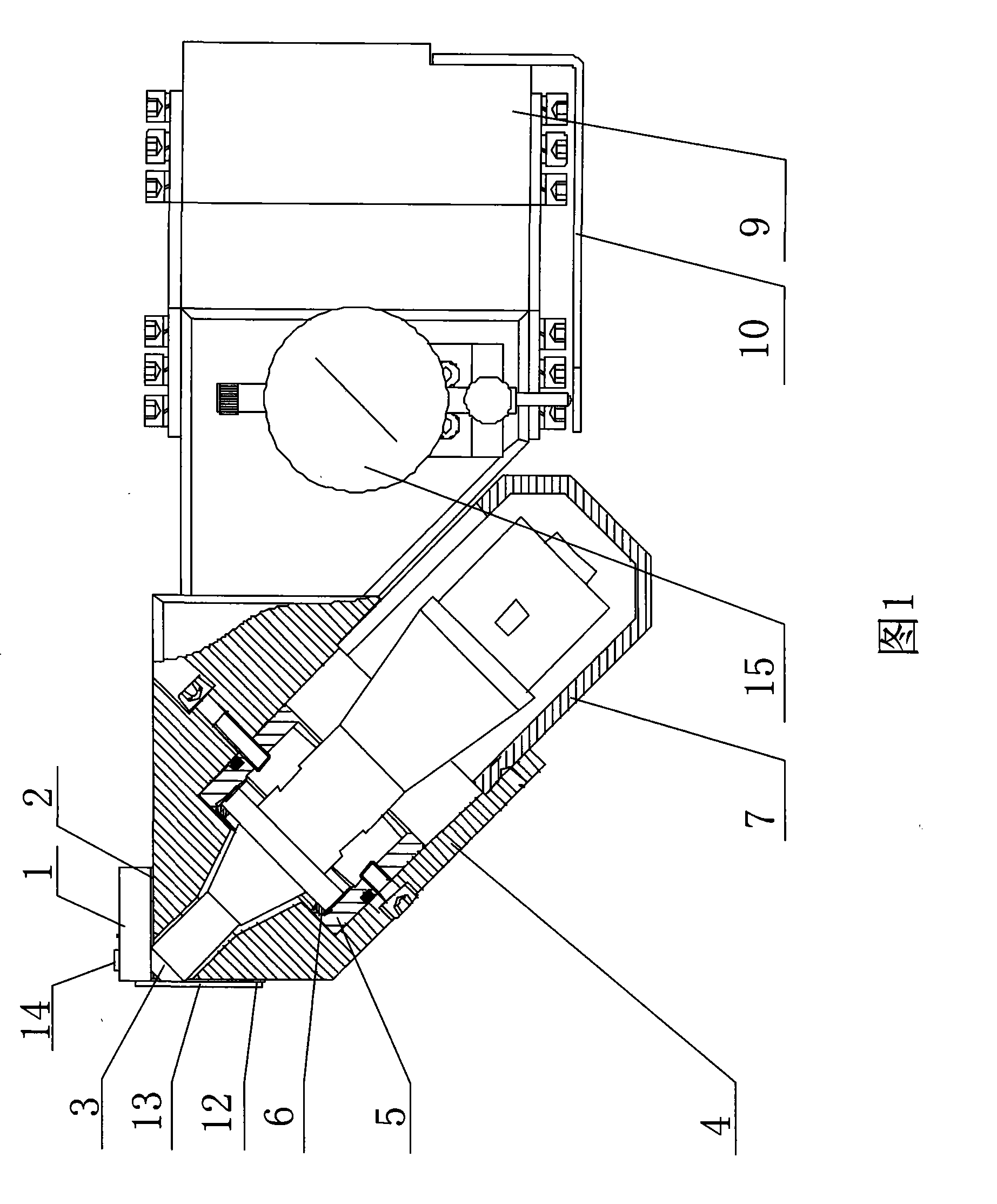

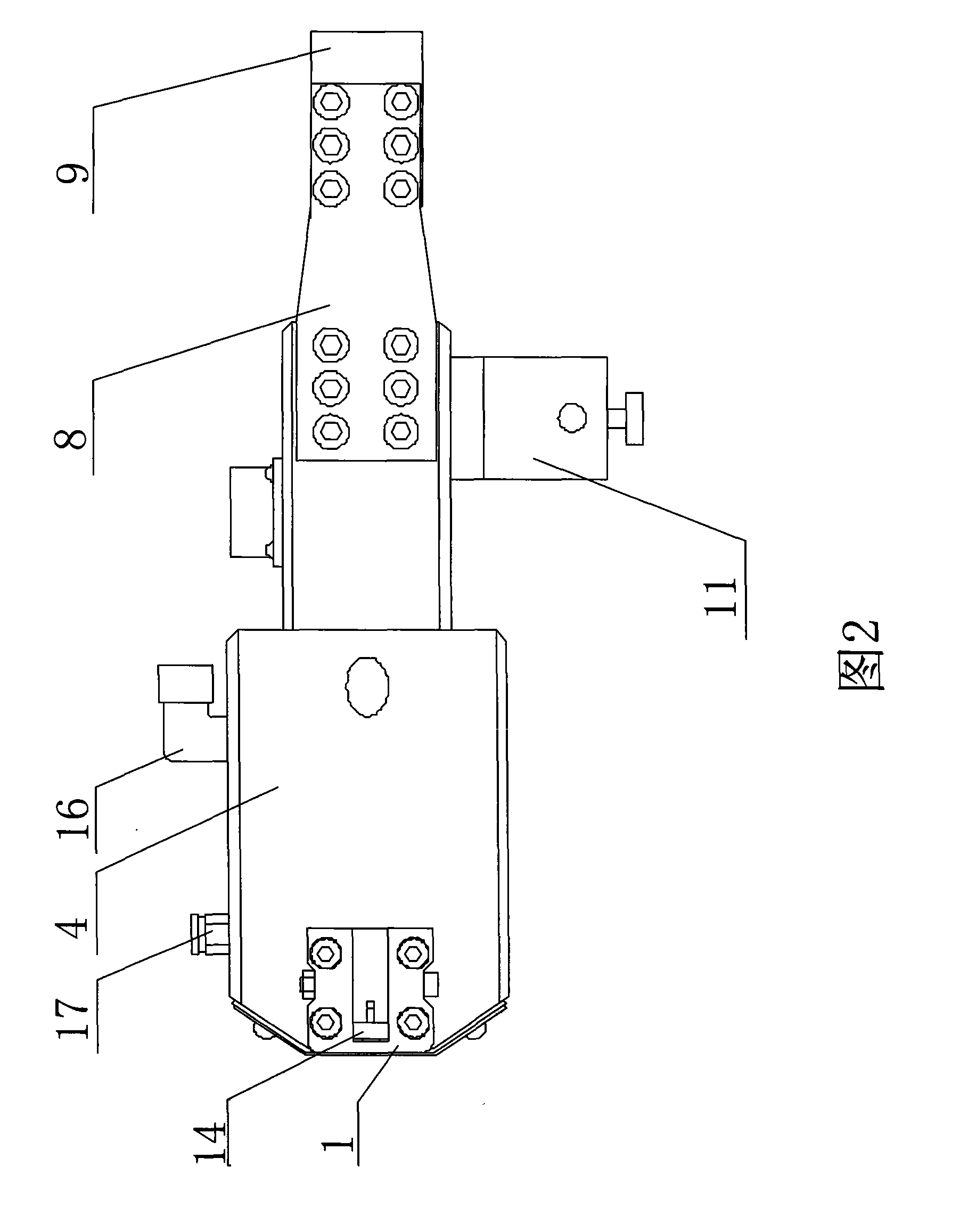

[0021] Attached below figure 1 , 2 The ultrasonic metal surface machining tool of the present invention will be described in detail below.

[0022] as attached figure 1 , 2 As shown, the ultrasonic metal surface processing tool of the present invention has a structure including a tool head 1, a tool seat adjustment pad 2, a horn 3, a horn seat 4, a steel sleeve 5, a horn adjustment pad 6, and a rear end cover 7. Shrapnel 8, briquetting block 9, dial indicator baffle 10, dial indicator seat 11, oil baffle 12, oil baffle support 13, tool head 14 and dial indicator 15, tool head 1 is prior art, The tool head 1 is set on the horn seat 4 through the tool seat adjustment pad 2, the tool head 14 is arranged on the tool head 1, the steel sleeve 5 is fixed in the hole of the horn seat 4 by bolts, and the horn 3 is set on the The horn base 4 is in contact with the inner surface of the steel sleeve 5, the horn 3 and the steel sleeve 5 are adjusted through the horn adjustment pad 6 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com