Pre-tightening structure of main shaft with rectangular attached cutting head

A cutting head and spindle technology, applied in metal processing equipment, metal processing mechanical parts, drive devices, etc., can solve problems such as affecting the accuracy of right-angle cutting heads, the diameter of the spindle end face, and affecting the accuracy of the spindle, so as to avoid uneven loading. , The effect of reducing error accumulation and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

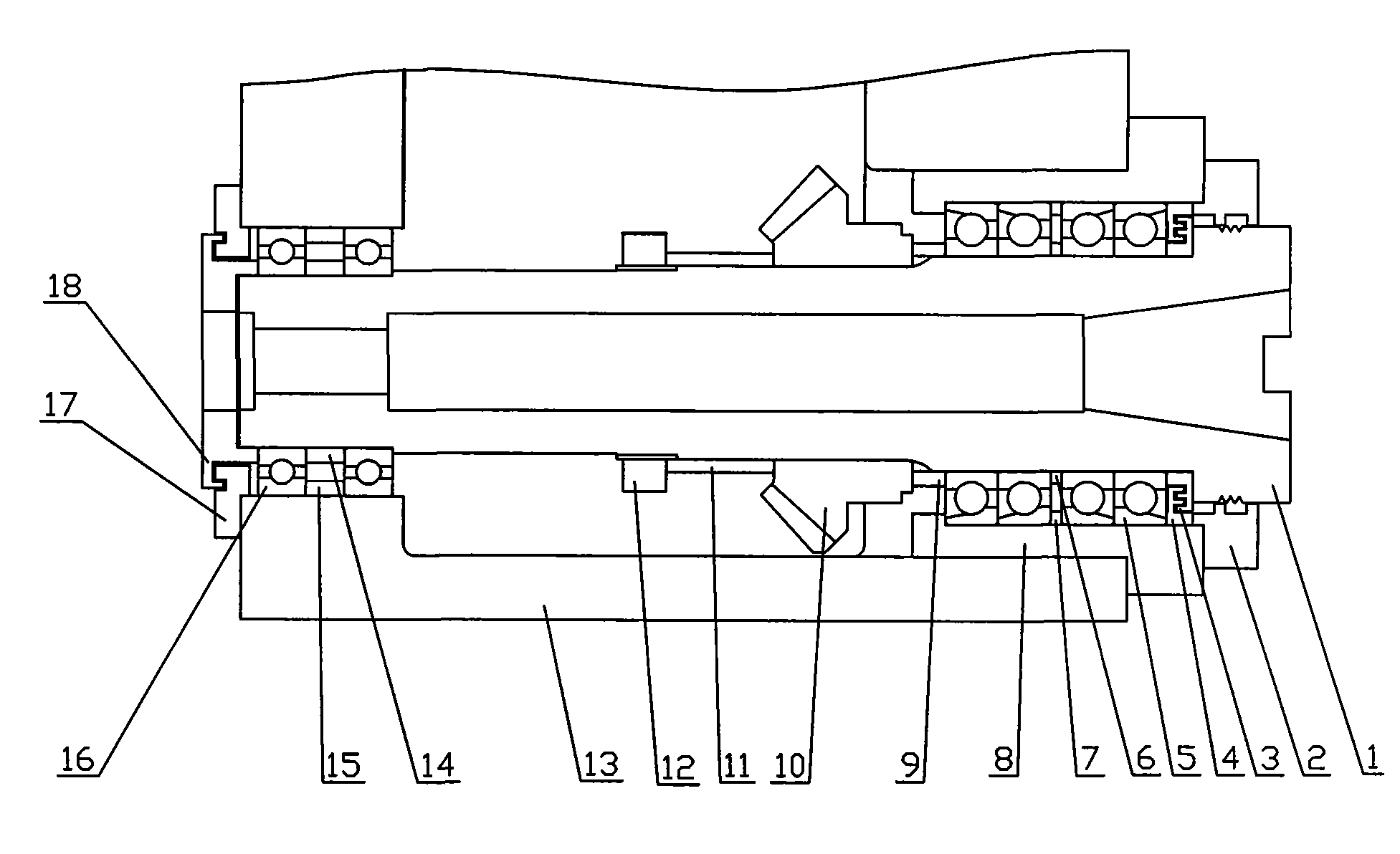

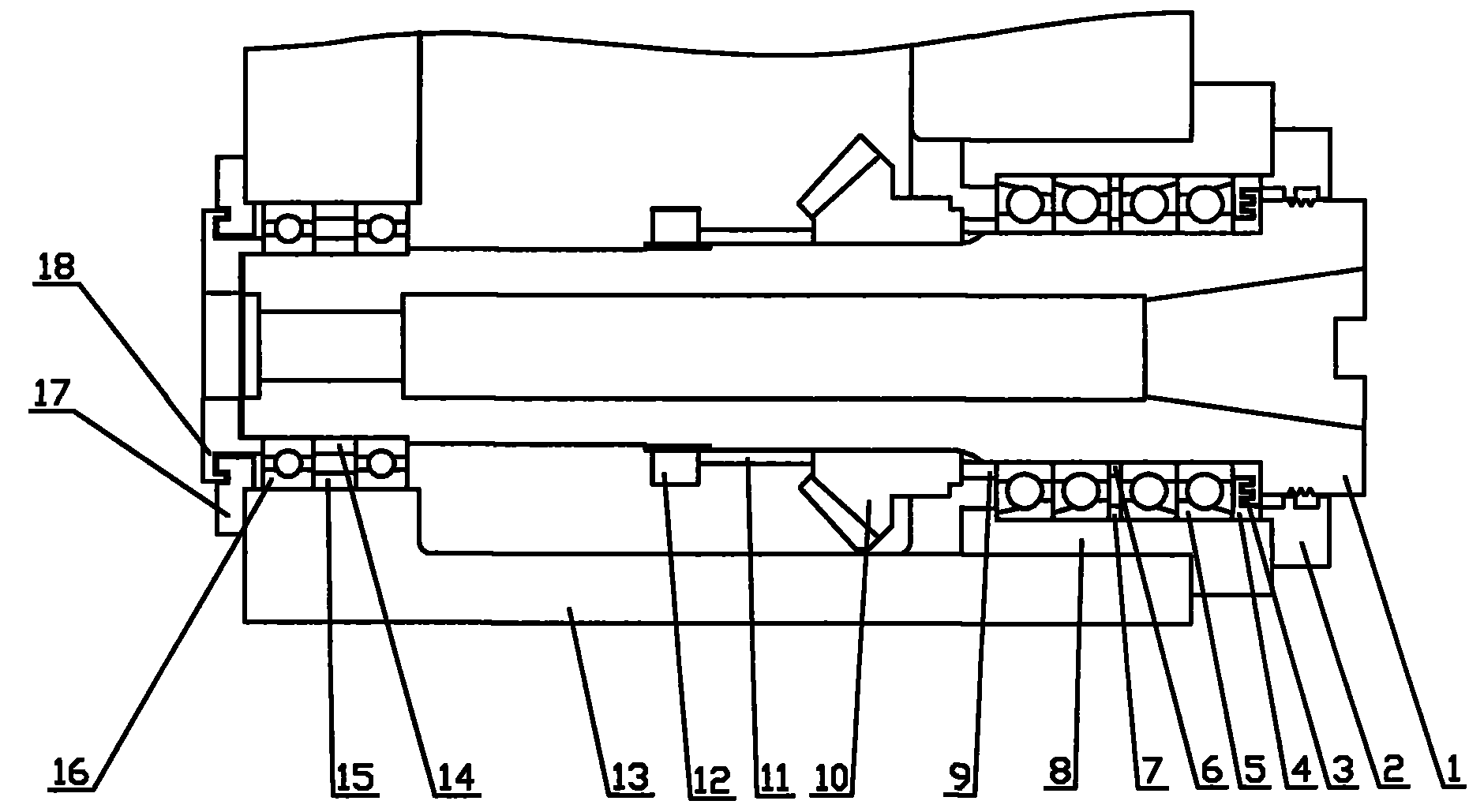

[0010] Such as figure 1 As shown, it includes the main shaft 1, the first flange cover 2, the labyrinth seal ring 3, the labyrinth seal ring 4, the angular contact bearing 5, the first spacer ring 6, the second spacer ring 7, the bearing seat 8, and the third spacer ring 9 , bevel gear 10, shaft sleeve 11, lock nut 12, box body 13, fourth spacer 14, fifth spacer 15, deep groove ball bearing 16, second flange cover 17 and third flange cover 18, etc. .

[0011] In the present invention, the first bearing assembly composed of four angular contact bearings 5, the first spacer ring 6 and the second spacer ring 7 is installed in the bearing seat 8, and the bearing seat 8 is fastened to the box body 13 with screws. The first The first spacer ring 6 of the bearing assembly cooperates with the main shaft 1; the first labyrinth seal ring 3 and the second labyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com