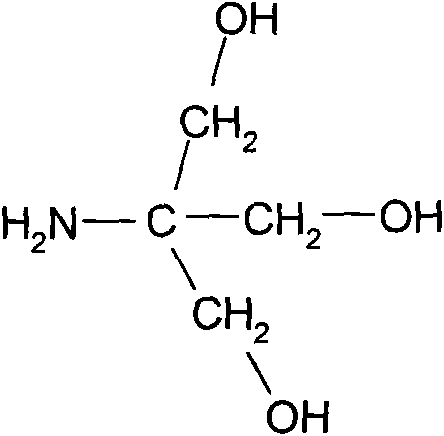

Method for synthesizing hydrophilic chromatographic medium by using trihydroxymethyl aminomethane genin and agarose

A trishydroxymethylaminomethane, synthesis method technology, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems of few types and low market share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, Synthesis Method 1 of Sepharose Hydrophilic Adsorption Chromatography Medium of Tris Hydroxymethylaminomethane

[0036] 1) 100ml of agarose gel microspheres with a concentration of 12% and an average particle size of 30μm are washed with water on a sand core funnel and replaced with acetone, transferred to a reaction bottle or reactor, and 100ml of acetone is added;

[0037] 2) Add 10g of glycidyl ether and stir for 60min;

[0038] 3) Add 3ml of 20% sodium hydroxide and stir for 8h;

[0039] 4) Add acetone and stir for 1h;

[0040] 5) Wash with 5 times the volume of acetone for 10 minutes, and wash with 5 times the volume of water for 10 minutes;

[0041] 6) Add 200ml of water, add 5g of sodium sulfate, and stir for 2h;

[0042] 7) Add 3ml of 20% sodium hydroxide and stir for 1h;

[0043] 8) Add 10ml of epichlorohydrin and stir at 35-60°C for 3h;

[0044] 9) wash with 5 times the volume of water;

[0045] 10) Add 200ml of water, add 5g of sodium sulf...

Embodiment 2

[0055] Embodiment 2, Synthesis Method 2 of Sepharose Hydrophilic Adsorption Chromatography Medium of Tris Hydroxymethylaminomethane

[0056] 1) 100ml of agarose gel microspheres with a concentration of 12% and an average particle size of 30μm are washed with water on a sand core funnel and replaced with acetone, transferred to a reaction bottle or reactor, and 100ml of acetone is added;

[0057] 2) Add 30g glycidyl ether and stir for 120min;

[0058] 3) Add 3ml of 20% sodium hydroxide and stir for 12h;

[0059] 4) add acetone and stir for 2h;

[0060] 5) Wash with 5 times the volume of acetone for 20 minutes, and wash with 5 times the volume of water for 20 minutes;

[0061] 6) Add 200ml of water, add 15g of sodium sulfate, and stir for 3h;

[0062] 7) Add 3ml of 20% sodium hydroxide and stir for 2h;

[0063] 8) Add 10-30ml of epichlorohydrin and stir at 40°C for 5h;

[0064] 9) wash with 5 times the volume of water;

[0065] 10) Add 200ml of water, add 15g of sodium sulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com