Liquid crystal display drive circuit

A liquid crystal display and drive circuit technology, applied to static indicators, instruments, etc., can solve problems such as incomplete display, insufficient humanization of products, and failure of drive circuits to work normally, and achieve the effect of strong humanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

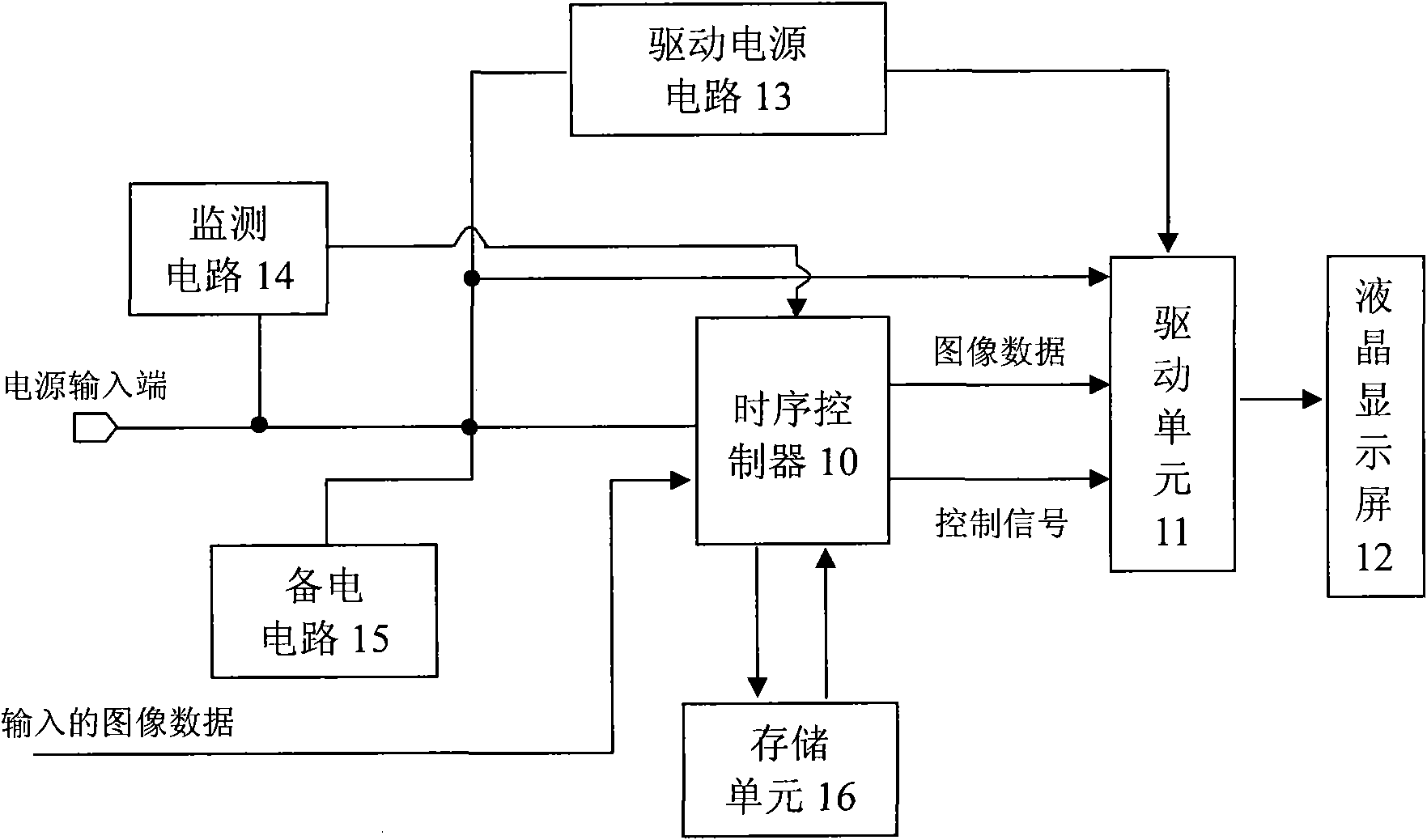

[0023] Such as figure 2 As shown, the liquid crystal display driving circuit of this embodiment includes a timing controller 10 connected to the input terminal of the power supply, the output terminal of the timing controller 10 is connected to the driving unit 11, and the output terminal of the driving unit 11 is connected to the liquid crystal display screen 12; wherein, the power input end is also connected with a drive power circuit 13, and the output end of the drive power circuit 13 is connected to the drive unit 11; the power input end is also connected with a monitoring circuit 14, and the monitoring The output end of circuit 14 is connected to described timing controller 10; The input end of described timing controller 10, driving power supply circuit 13 and drive unit 11 is also connected with backup power circuit 15; Described timing controller 10 is also connected with storage Unit 16 is used for storing the data of the power-off prompt screen.

[0024] During no...

Embodiment 2

[0039] It is generally the same as Embodiment 1, except that the liquid crystal display driving circuit of this embodiment is further provided with a backlight source monitoring circuit 18 .

[0040] Such as Figure 5 As shown, the backlight monitoring circuit 18 includes a third reset chip, the ground terminal of the third reset chip is grounded, and the input terminal is connected to the backlight power signal terminal of the liquid crystal display 12 (ie Figure 5 In B / L Vddin), the output end is connected to the timing controller, and at the same time, it is also connected to the resistor R5 and then grounded; the connection line between the output end of the third reset chip and the timing controller is also connected to the third reset chip through the resistor R4 input terminal. Resistors R4 and R5 can realize voltage division of the backlight power supply, which is convenient for monitoring by the third reset chip. If the third reset chip detects that the divided bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com