System and method thereof for checking product quality

A product quality and inspection system technology, which is applied in the direction of optical testing for defects/defects, can solve problems such as quality control errors, high error rates of inspection results, and difficult to see defects, and achieve the effect of reducing error rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

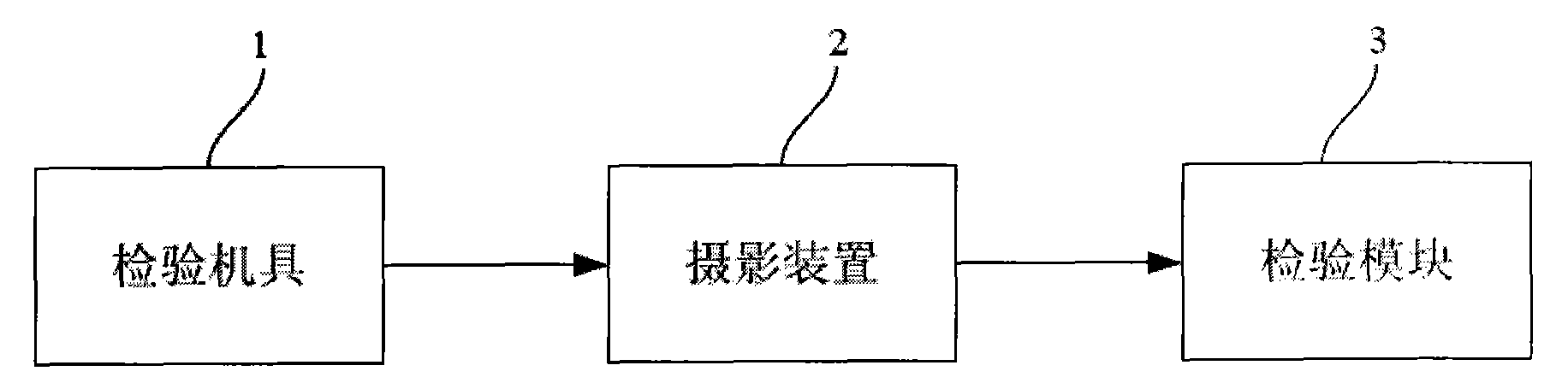

[0019] see figure 1 Shown is the architecture diagram of the inspection system of product quality provided by the present invention, and the system mainly includes:

[0020] An inspection tool 1, the inspection tool 1 is used for product placement and positioning, so that the product stands on the inspection tool 1;

[0021] A camera device 2, the camera device 2 is erected on the inspection tool 1, and is set corresponding to the product fixed on the inspection tool 1, the corresponding relationship between the two positions is kept constant, and can be adjusted through the inspection tool 1 device for adjusting the shooting focal length of the photographing device 2, so that the photographing device 2 can take clear images; in addition, the photographing device 2 can be a camera or a video camera;

[0022] An inspection module 3, the inspection module 3 is connected with the photographic device 2, so that the inspection module 3 can receive and store the image taken by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com