Slot mortise coupling structure

A joint structure and tenon-groove technology, which is applied in the direction of connecting components, furniture connection, mechanical equipment, etc., can solve the problems of unsightly appearance, low connection strength, easy to fall off, etc., achieve good firmness, ensure firmness, and enhance pre-tightening force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

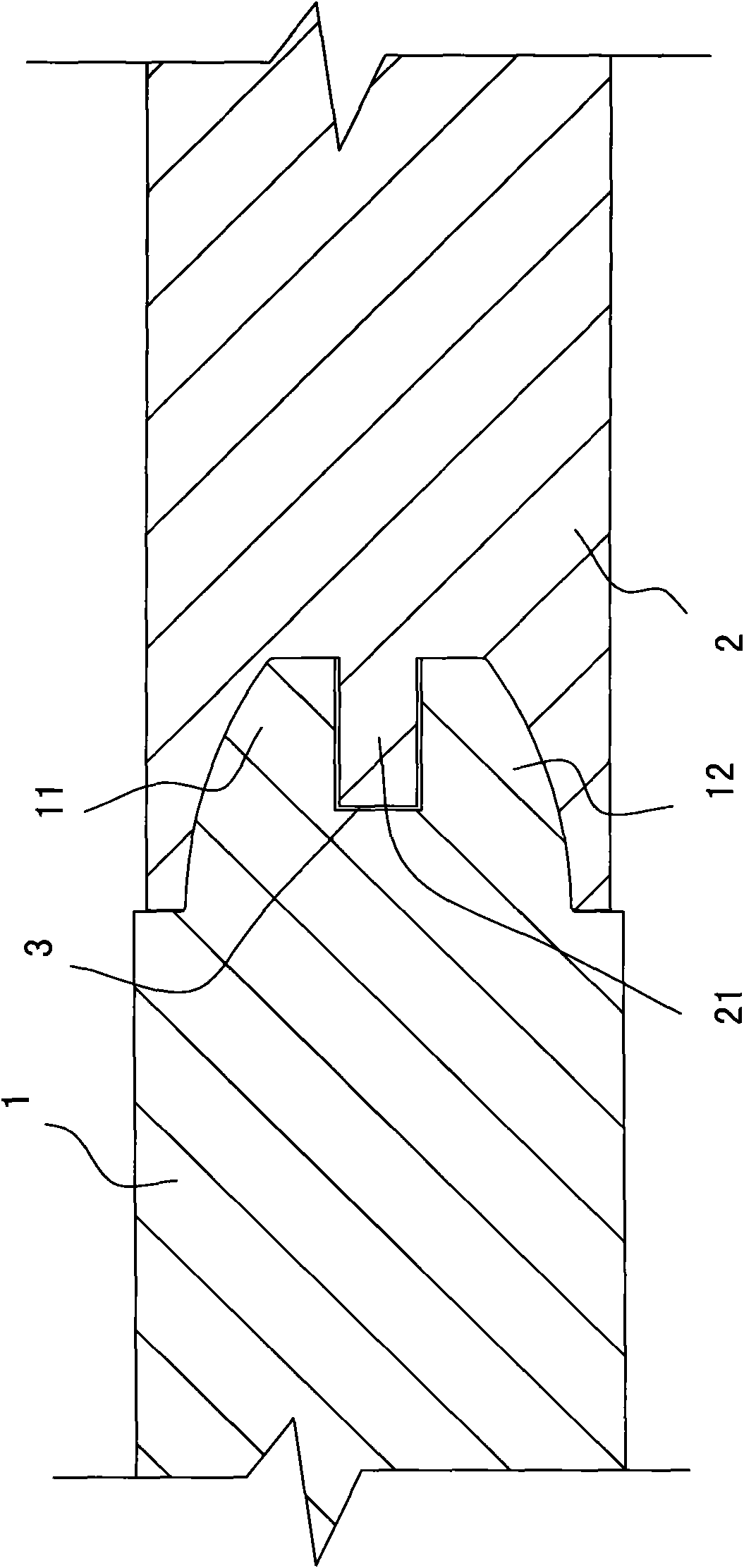

[0012] see figure 1 . The connecting part of the component 1 is a tenon, and the tenon is composed of an upper tenon 11 and a lower tenon 12 , and a convex inner groove 3 is provided in the middle of the upper tenon 11 and the lower tenon 12 . The connecting part of the component 2 matches the connecting part of the component 1, and the concave tenon 21 is arranged in the middle of the entire groove. Of course, the shapes of the tenon and the groove, and the shapes of the convex inner groove 3 and the concave inner tenon 21 can be deformed as required, as long as they match each other.

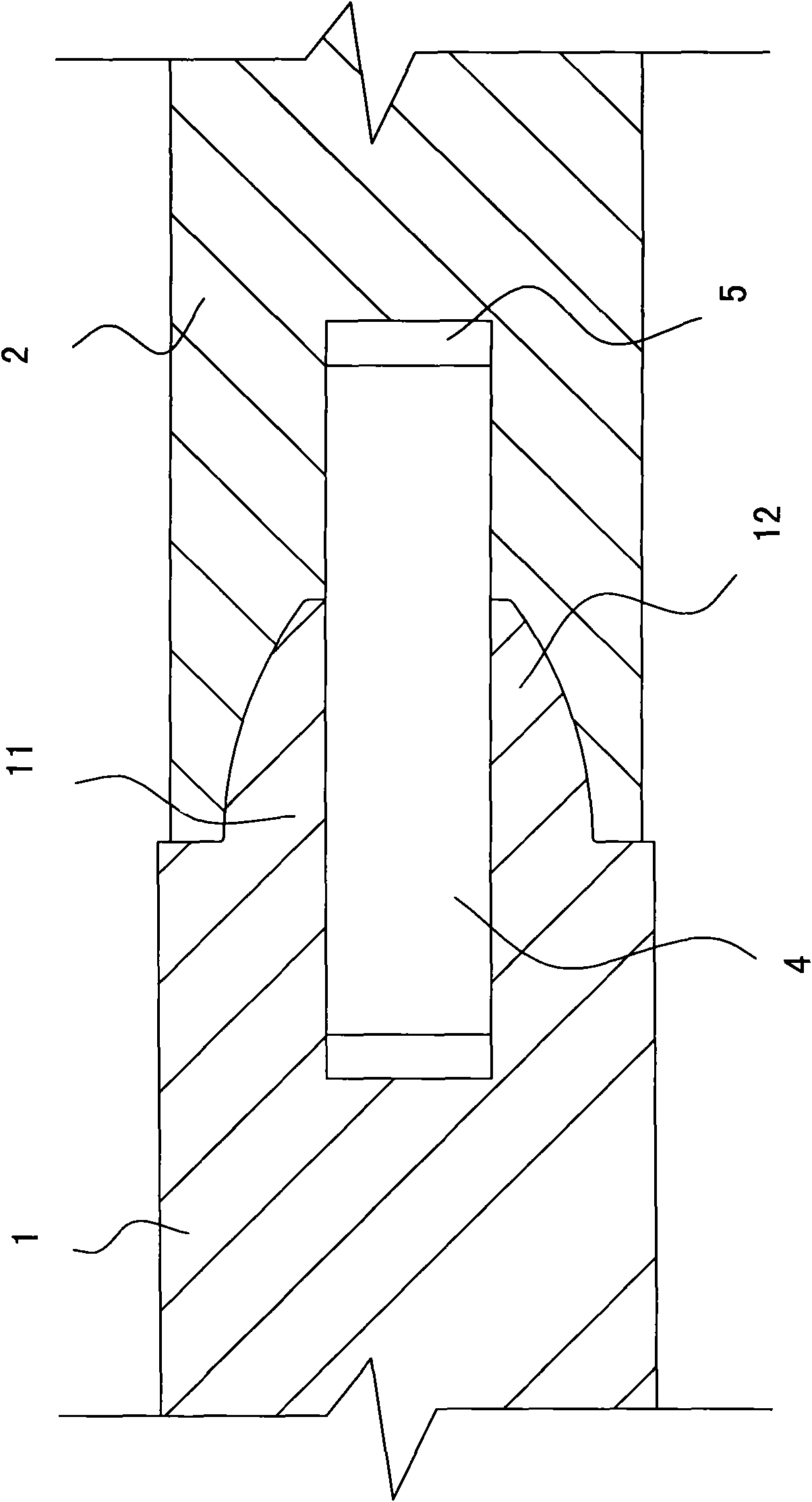

[0013] see figure 2 . Considering that the thickness of component 1 and component 2 is relatively thin, it is not suitable to use figure 1 The shown structure, therefore, adopts the following modified structure. Its deformation is: 1, will figure 1 The concave and tenon 21 in the middle evolves into an independent part pin, and the pin is preferably with the log pin 4; 2, open a seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com