Large-aperture thin-wall anodized aluminum film and preparation method thereof

An anodized aluminum, anodic oxidation technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of only 30-70nm, filled with other substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The aluminum flakes are first ultrasonically cleaned with acetone, ethanol, and high-purity water for 10 minutes to remove surface grease and dirt; the cleaned aluminum flakes are placed in a 5% sodium hydroxide solution for 30 minutes to remove the aluminum flakes. oxide layer on the surface. Put the prepared aluminum sheet into a 1% phosphoric acid solution by mass percentage for anodic oxidation: first anodize at a high voltage of 160 volts for 3 minutes, then reduce the voltage to 120 volts, and continue anodizing for 1 hour.

[0018] The product obtained in this embodiment is a thin-walled anodic aluminum oxide film with large pores.

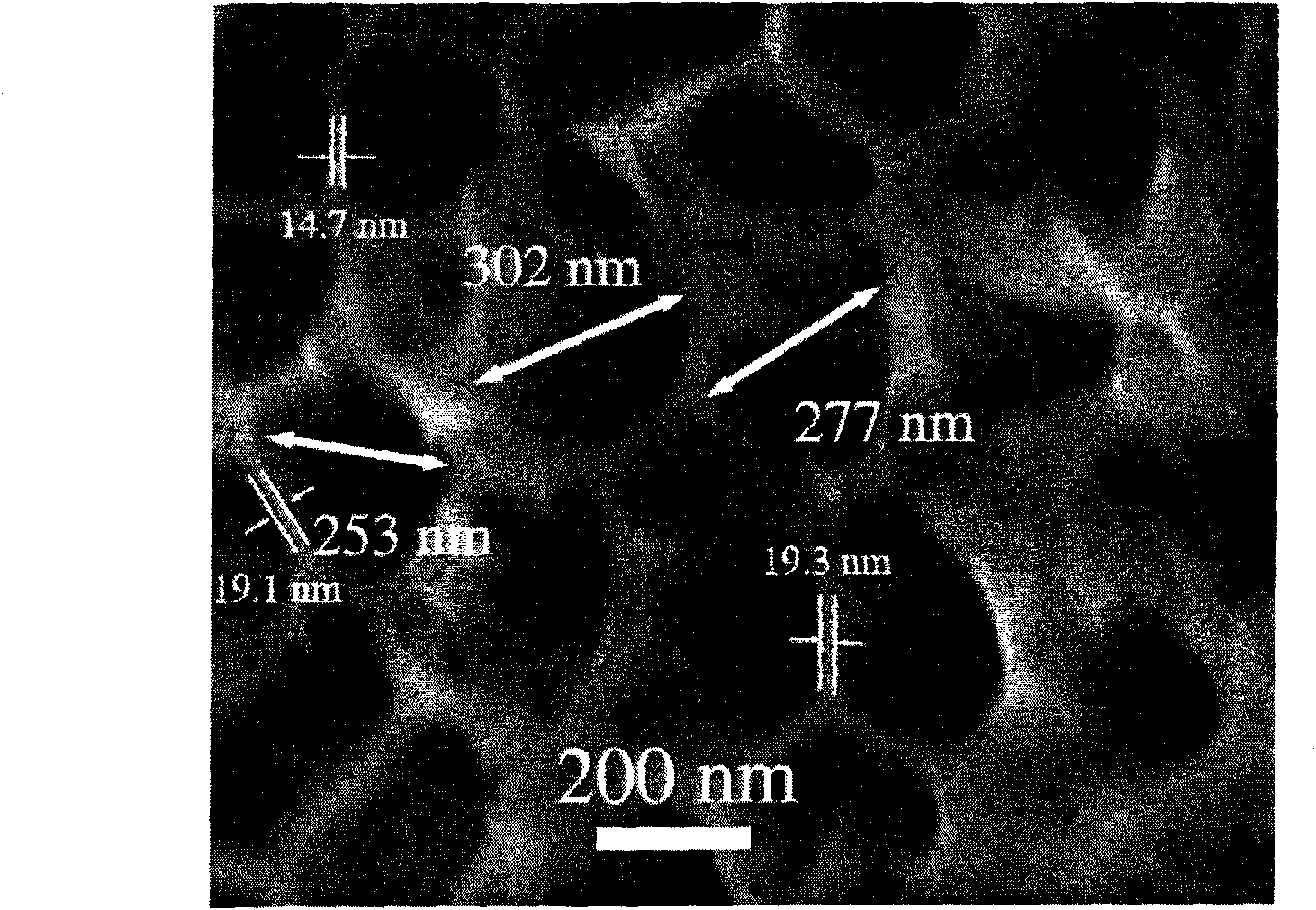

[0019] figure 1 Shown is the scanning electron microscope picture of the large-aperture thin-walled anodized aluminum produced in this example. The anodized aluminum in the picture has a pore diameter of 250-300 nm and a pore wall thickness of 14-20 nm.

Embodiment 2

[0021] The aluminum flakes are first ultrasonically cleaned with acetone, ethanol, and high-purity water for 10 minutes to remove surface grease and dirt; the cleaned aluminum flakes are placed in a 5% sodium hydroxide solution for 30 minutes to remove the aluminum flakes. oxide layer on the surface. Put the prepared aluminum sheet into a 1% phosphoric acid solution by mass percentage for anodic oxidation: during anodic oxidation, the concentration of phosphoric acid is 1%, anodic oxidation is performed at a high voltage of 160 volts for 5 minutes, and then the voltage is reduced to 40 volts , continue anodizing for 10 hours.

[0022] The product obtained in this embodiment is a thin-walled anodic aluminum oxide film with large pores.

Embodiment 3

[0024] The aluminum flakes are first ultrasonically cleaned with acetone, ethanol, and high-purity water for 10 minutes to remove surface grease and dirt; the cleaned aluminum flakes are placed in a 5% sodium hydroxide solution for 30 minutes to remove the aluminum flakes. Oxidation layer on the surface; the aluminum sheet that is put into mass percentage is that 2% phosphoric acid solution, carry out anodic oxidation: at first under the high voltage of 120 volts anodic oxidation 30 minutes, then reduce voltage to 80 volts, continue anodic oxidation 5 Hour.

[0025] The product obtained in this embodiment is a thin-walled anodic aluminum oxide film with large pores.

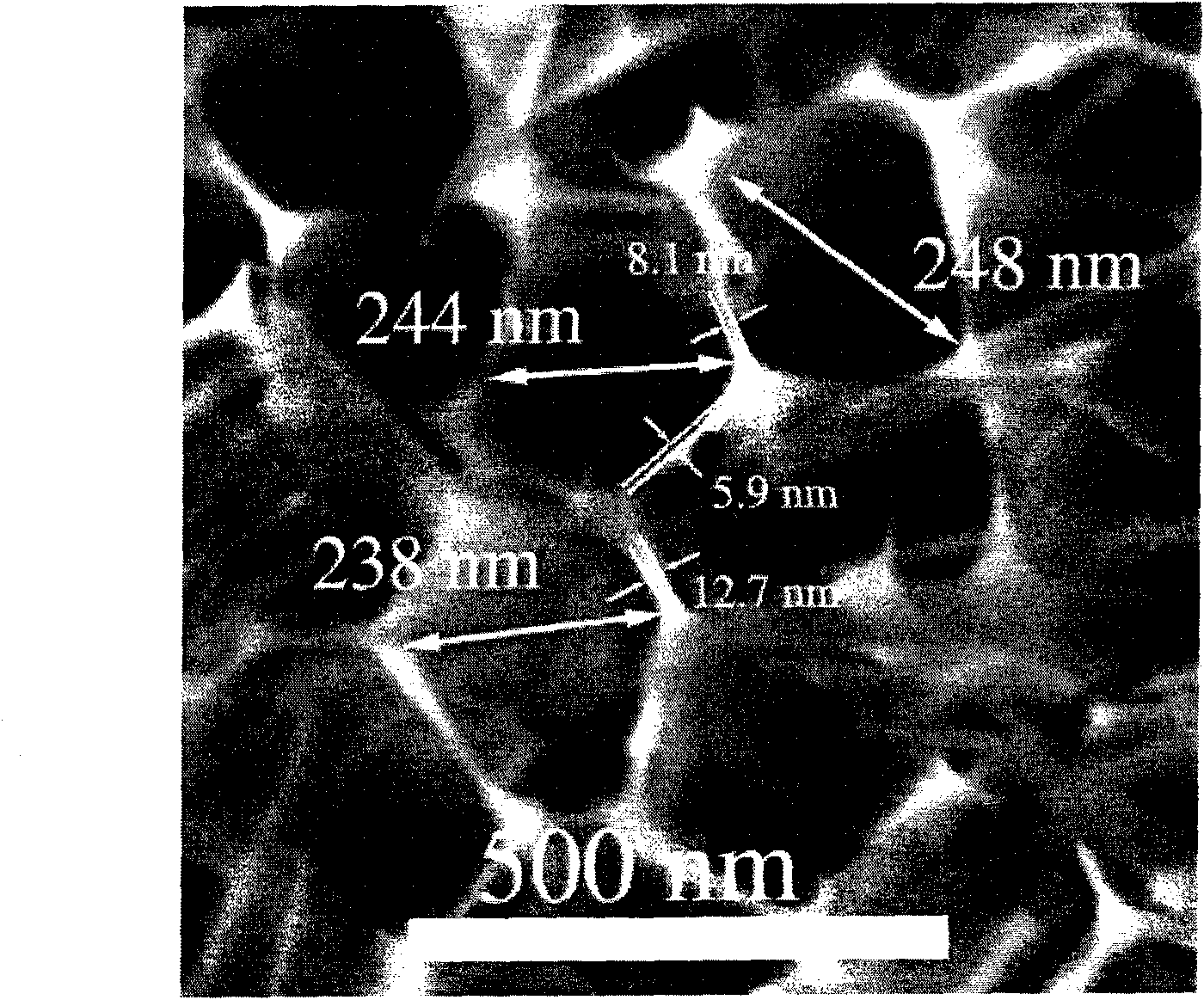

[0026] figure 2 Shown is the scanning electron microscope picture of the large-aperture thin-walled anodized aluminum prepared in this example. The anodized aluminum in the picture has a pore diameter of 240-250 nm and a pore wall thickness of 5-13 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole wall thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com