Composition for removing scale, preparation method and applications thereof

A composition and scale technology, applied in cleaning methods and utensils, chemical instruments and methods, complex/solubilizer treatment, etc., can solve the problems of low efficiency, long scale removal time, etc., and achieve low corrosion rate and accelerated dissolution rate. , the effect of improving the ability to dissolve scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Formula (weight ratio):

[0028] Cleaning agent: sulfamic acid 10%

[0029] Penetrant JFC 1‰

[0030] Sodium tripolyphosphate 3%

[0031] Water 86.9%

[0032] Corrosion inhibitor CM-911 1‰ of cleaning agent weight

[0033] preparation:

[0034] 1. According to the total amount of cleaning agent required, weigh each component material according to the formula percentage requirements;

[0035] 2. First add the water in the stated proportion into the blended cleaning agent container, then add the corrosion inhibitor CM-911 in the stated proportion, and stir evenly;

[0036] 3. Slowly add the sulfamic acid in the stated proportion, stir while adding, add the sodium tripolyphosphate in the stated proportion after the sulfamic acid is dissolved, and stir until it is fully dissolved; finally add the penetrating agent in the stated proportion (JFC), fully stirred, obtained descaling agent product A.

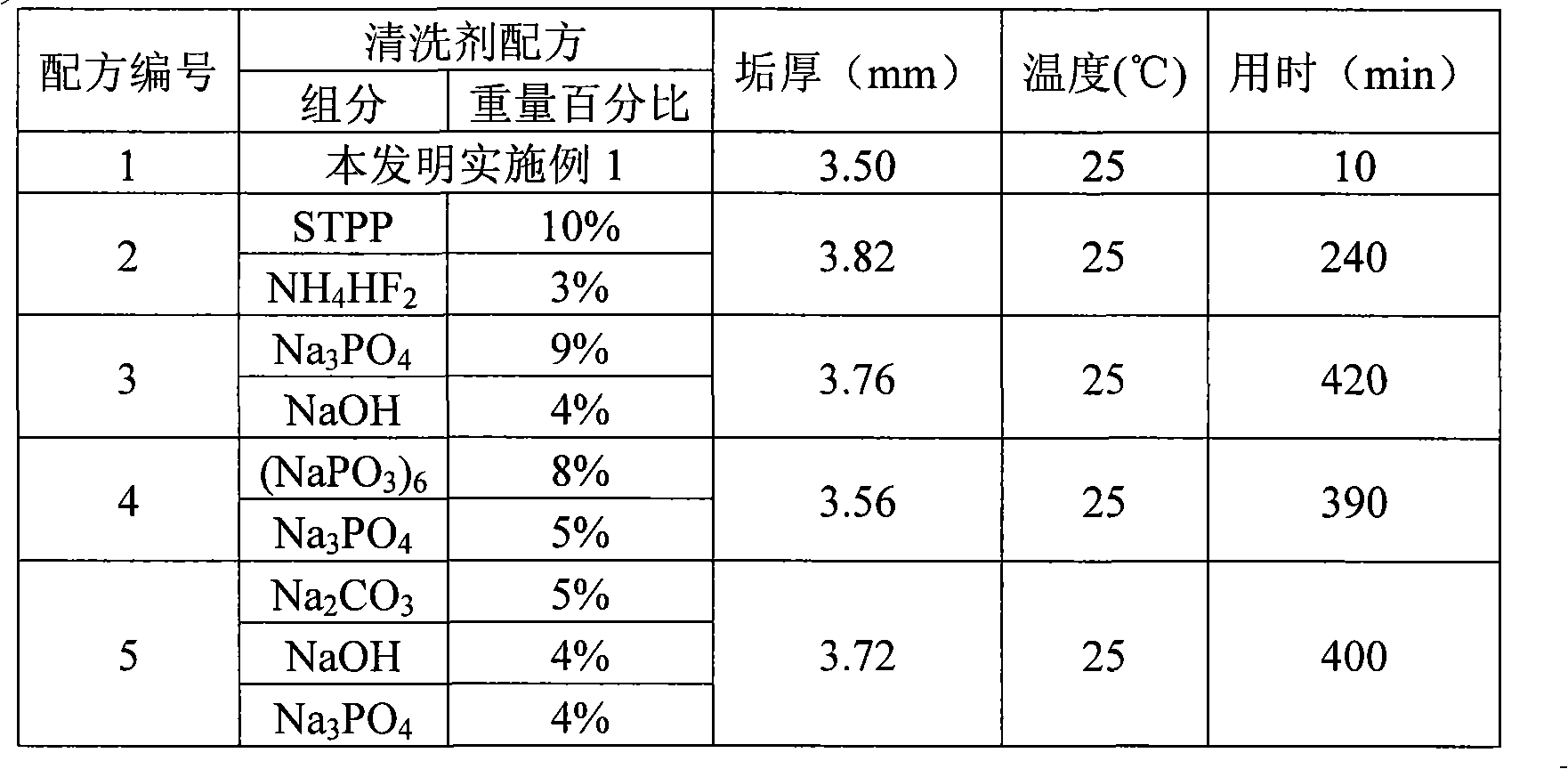

[0037] Descaling test:

[0038] Carry out cle...

Embodiment 2

[0042] Formula (weight ratio):

[0043] Cleaning agent: sulfamic acid 2%

[0044] Penetrant JFC 0.5‰

[0045] Sodium tripolyphosphate 5%

[0046] Water 93%

[0047] Corrosion inhibitor CM-911 1‰ of cleaning agent weight

[0048] Preparation: The method is the same as in Example 1 to obtain product B.

[0049] Descaling application:

[0050] The obtained product B can be used to remove the carbonate scale on the surface of the stainless steel liner of the household water heater, and the cleaning temperature is 45°C.

Embodiment 3

[0052] Formula (weight ratio):

[0053] Cleaning agent: sulfamic acid 50%

[0054] Penetrant JFC 5‰

[0055] Sodium Tripolyphosphate 10%

[0056] Water 39.5%

[0057] Corrosion inhibitor CM-911 2‰ of cleaning agent weight

[0058] Preparation: The method is the same as in Example 1 to obtain product C.

[0059] Descaling application:

[0060] The prepared product C can be used to remove the carbonate scale on the inner surface of the water tank of the automobile, and the cleaning temperature is 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com