Rail hook device for floating dock portal crane

A technology for cranes and dock doors, used in safety devices, travel mechanisms, transportation and packaging, etc., can solve problems such as insecurity, large size of hook-rail devices, multiple sliding friction and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

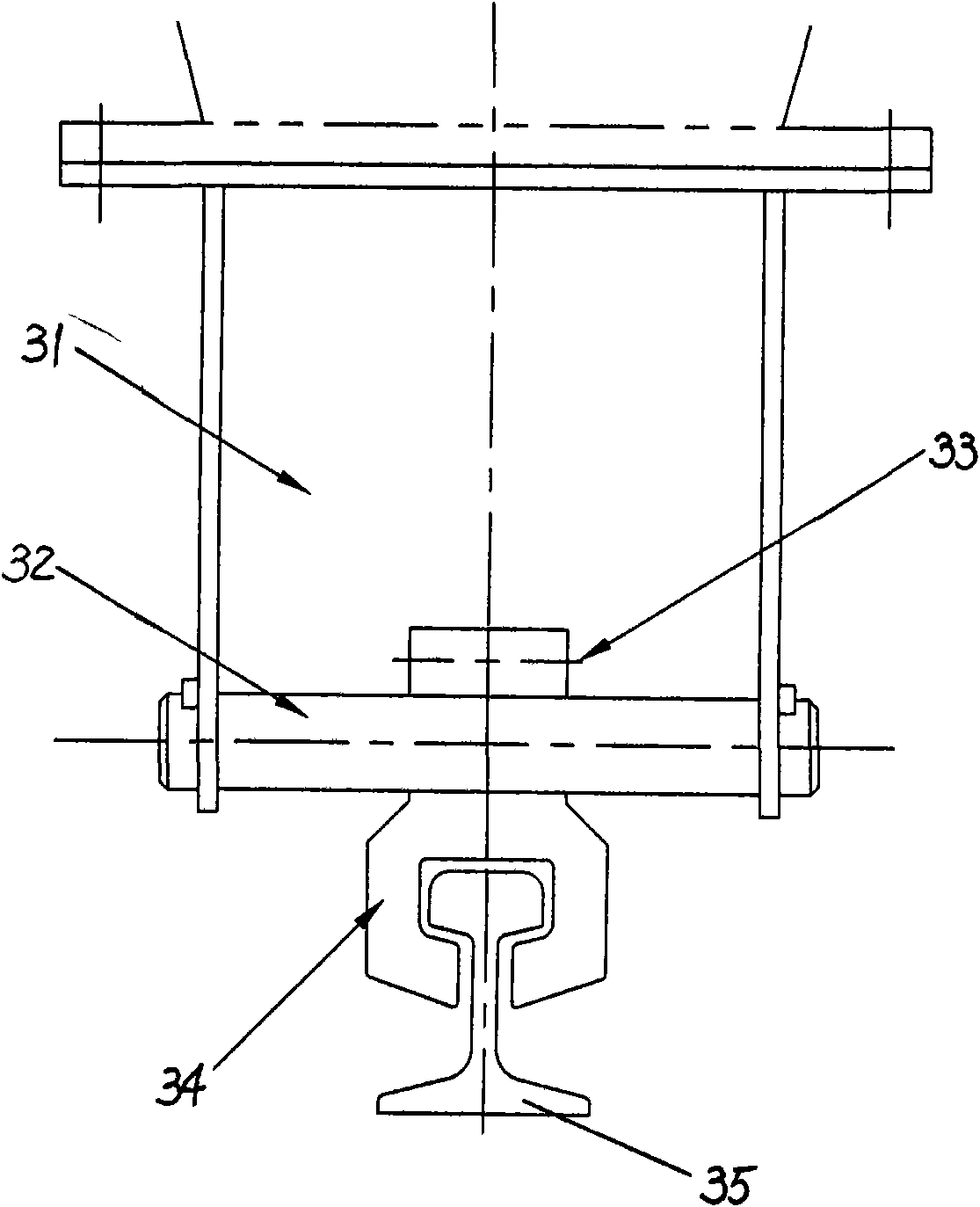

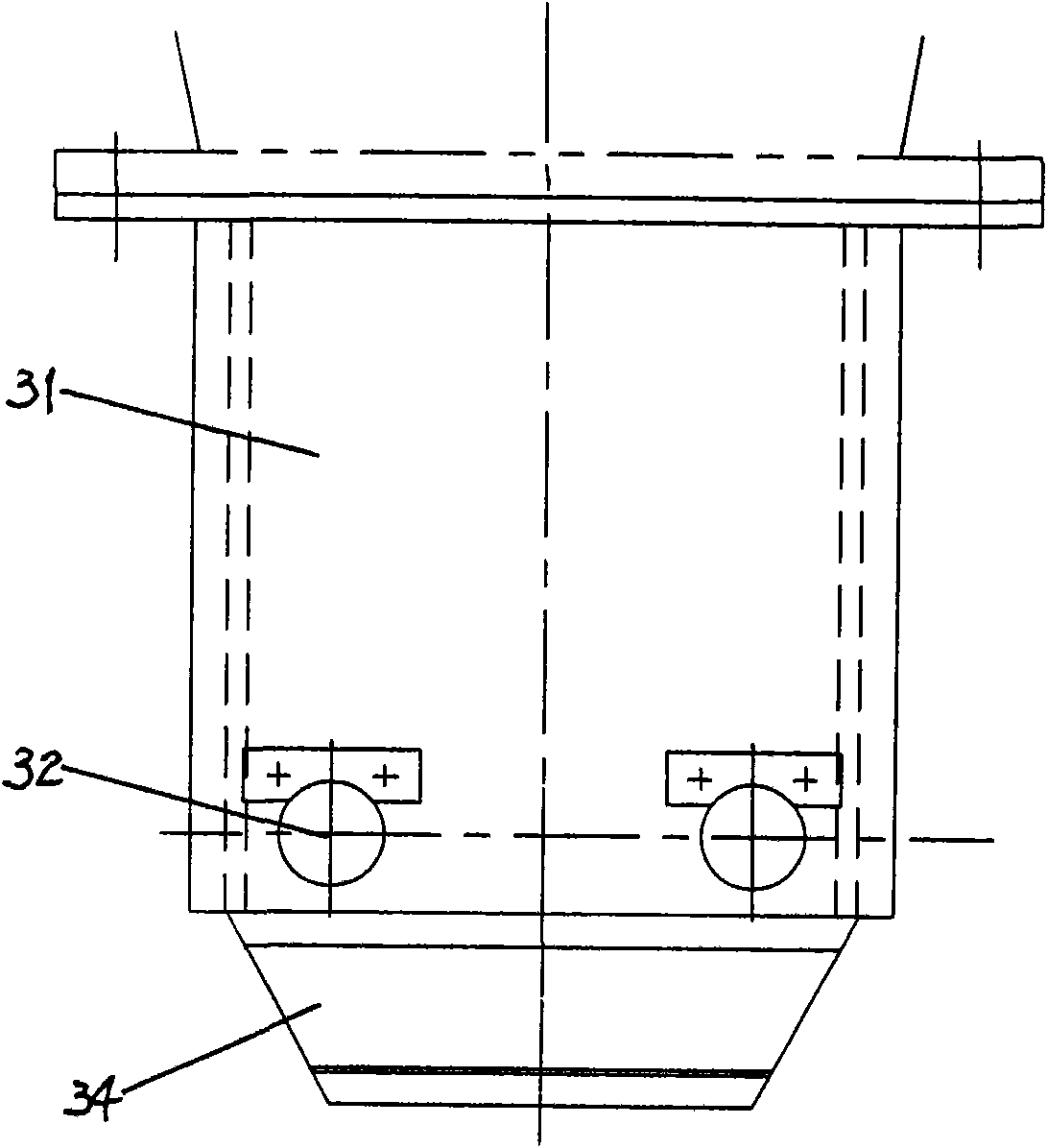

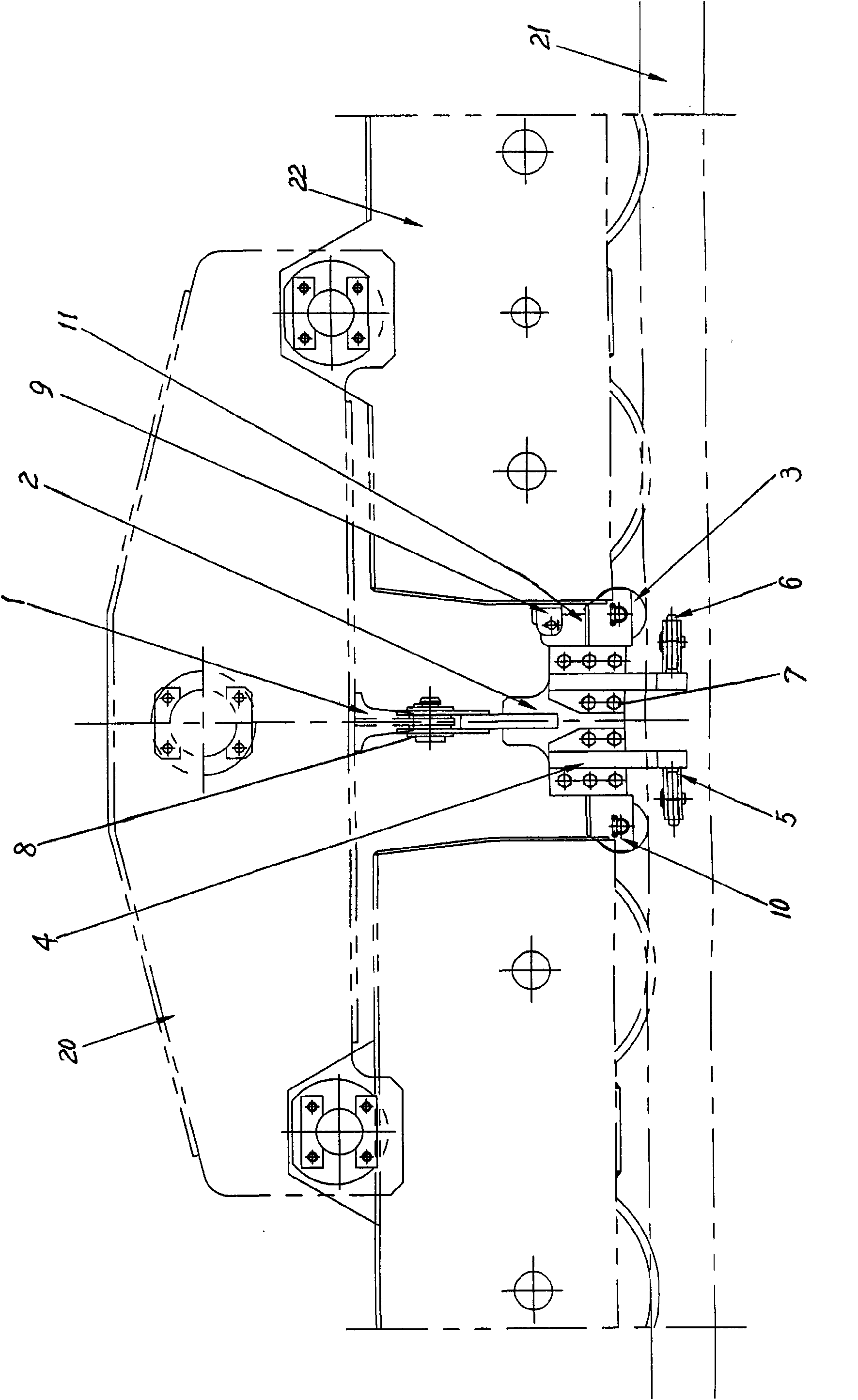

[0039] Attached below Figure 3-7 A preferred embodiment of a hook rail device for a floating dock portal crane of the present invention will be specifically introduced.

[0040] see Figure 3 to Figure 5 , the present invention is a hook rail device for a floating dock portal crane, which is installed between two trolleys 22 of the traveling mechanism, and installed along the track 21 at the bottom of the balance beam 20 of the traveling mechanism.

[0041] The hook rail device of the present invention consists of a pull plate 1, a connecting plate 2, a running wheel 3, a hook plate 4, a pivot ear 5, a horizontal guide wheel 6, a bolt pair 7, a pivot hole 8, a pivot shaft and a clamping plate 18, Pull ear 9, bearing 10, monolithic bearing 11, cotter pin 12, pin with hole 13 and bearing 14 form.

[0042]Wherein, the pull plate 1 is welded on the bottom of the balance beam of the traveling mechanism. The connecting plate 2 is hinged on the bottom of the drawing plate 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com