Rotation motor zero calibrating method for hybrid and electric automobile

A zero-point calibration and electric vehicle technology, which is applied in the direction of electronic commutation motor control, electrical components, and the use of electric/magnetic devices to transmit sensing components, etc., can solve problems such as unfavorable mass production of motors, and achieve the effect of simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

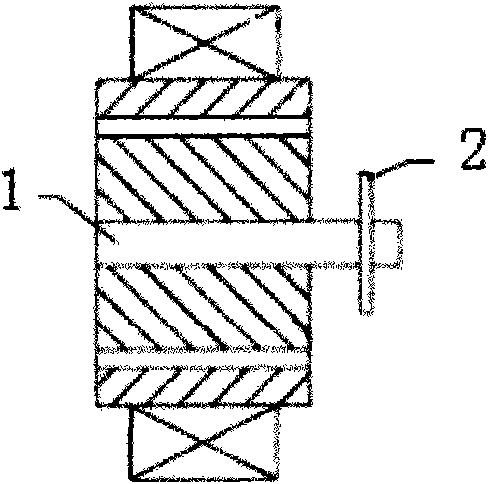

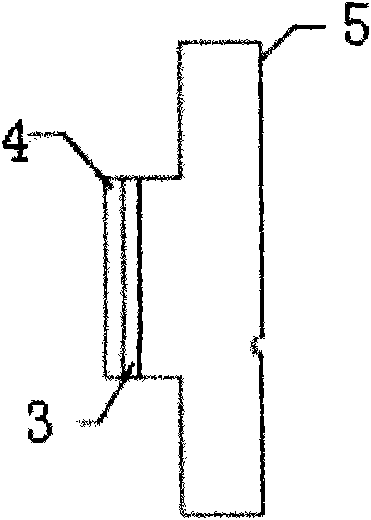

[0014] Such as figure 1 As shown, install the resolver rotor 2 on the motor shaft 1, such as figure 2 As shown, the resolver stator 3 is installed on the motor end plate 5 through the pressure plate 4, the resolver stator is provided on the pressure plate, and the threaded hole for fixing the resolver stator and the motor end plate is provided on the pressure plate, the The set screw is tightened so that the resolver stator can turn.

[0015] Decode the output signal of the resolver, output the decoded rotor position signal to the data analysis equipment, compare and process the back electromotive force waveform output by the motor to obtain the rotor phase difference that needs to be compensated, and input the difference to the fork motor After adjusting the position of the resolver stator through the fork motor, tighten the screws to fix the rotating stator and complete the zero point calibration of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com