Rotation motor zero calibrating method for hybrid and electric automobile

A zero-point calibration, electric vehicle technology, applied in electronic commutation motor control, electrical components, using electric/magnetic devices to transmit sensing components, etc., can solve problems such as unfavorable mass production of motors, and achieve the effect of simple and easy method.

Active Publication Date: 2011-01-05

CHERY AUTOMOBILE CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most motor manufacturers use a special test board to communicate with the motor to calculate the angle of rotation after the motor is installed, and then perform zero calibration by changing the parameters of the software. This method is extremely unfavorable to the motor. mass production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

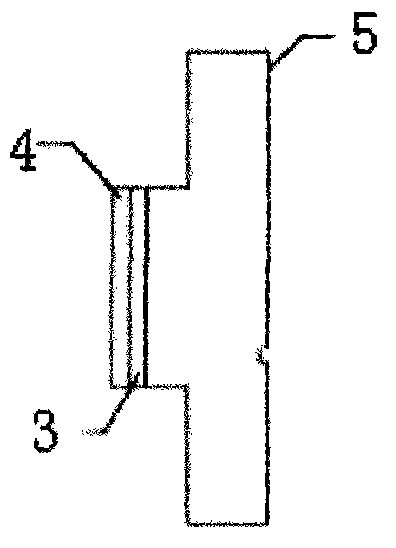

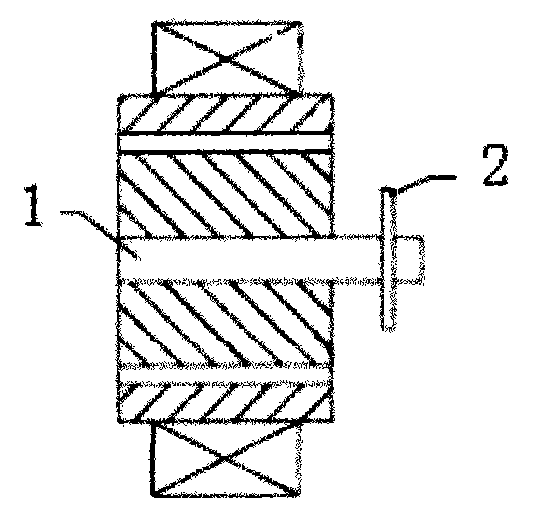

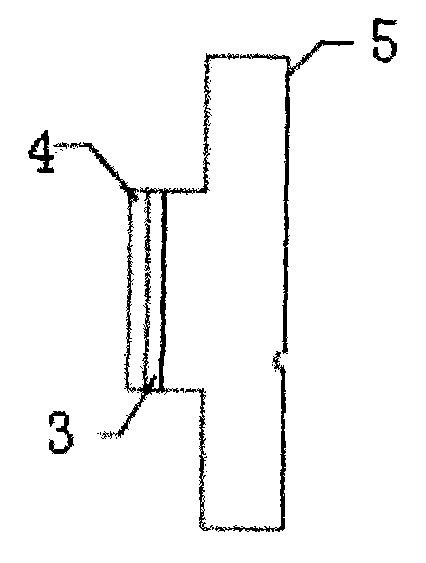

The invention relates to a rotation motor zero calibrating method for hybrid and electric automobile, suitable for batch production of motors. The rotation motor zero calibrating method for hybrid andelectric automobile is characterized in that: a rotation rotor is mounted on a motor axle and a rotation stator is mounted on the end plate of the motor and then pre-screwed up; the difference valueof the two signals are input into a shifting yoke motor, after detecting the motor rotor position signal and the motor stator position signal and the rotation stator is rotated by the shifting yoke motor to perform the difference value compensation and then the rotation stator screw is screwed up and fixed to calibrate the motor zero.

Description

A method for zero point calibration of resolver motors for hybrid and electric vehicles technical field The invention relates to a method for calibrating the zero point of a resolver motor used in hybrid power and electric vehicles. Background technique In recent years, due to energy shortage and environmental pollution, the development of the automobile industry has encountered unprecedented challenges. In order to solve these two major problems, the development of a new generation of clean and energy-saving vehicles has become an inevitable trend. Therefore, major automobile manufacturers have participated in the research and development of hybrid and pure electric vehicles, so that motors have been widely used in automobiles. Due to the obvious advantages of simple structure, reliable operation, small size, light weight, and flexible shape and size, permanent magnet synchronous motors have become the first choice for vehicles. The permanent magnet synchronous motor n...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02P6/00G01D5/12

Inventor 冯勇吴瑞宋波

Owner CHERY AUTOMOBILE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com