A connector sealing element

A technology of seals and connectors, which is applied in the direction of connections, components of connection devices, electrical components, etc., and can solve problems such as inability to detect holes 68

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

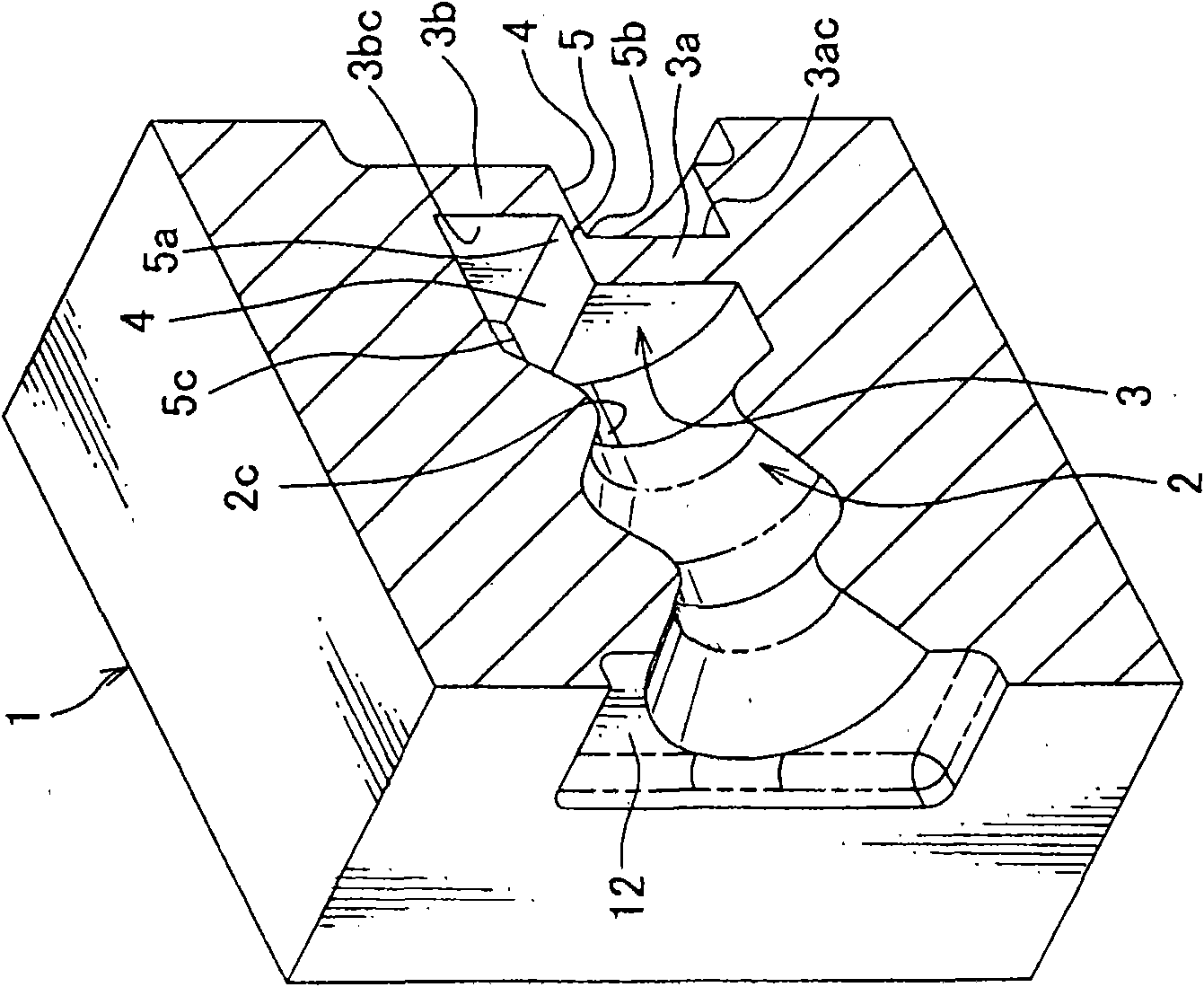

[0054] 1-4 show a first embodiment of the connector seal of the present invention.

[0055] see Figures 1A-2B , the connector seal 1 is made of (elastic) synthetic rubber, and has a plurality of terminal insertion holes 2 .

[0056] Each terminal insertion hole 2 has a diaphragm 3 including an upper diaphragm portion 3 a and a lower diaphragm portion 3 b. The upper and lower diaphragm portions 3 a , 3 b are spaced apart in the longitudinal direction of the terminal insertion hole 2 , and are connected to each other at the stepped portion 4 by the thin layer 5 .

[0057] see Figure 3A and 3B , when the terminal 6 is incorrectly inserted and taken out of the terminal insertion hole 2 , the vertical thin layer 5 of the diaphragm 3 breaks, and an opening 7 is formed in the radial or horizontal direction of the terminal insertion hole 2 . The chamber 2a below the upper membrane 3a and the chamber 2b above the lower membrane 3b then communicate with each other through the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com