Embedded small frame earthquake resistant structure of free of bearing force

A technology of anti-seismic structure and frame, applied in the direction of structural elements, anti-seismic, building components, etc., can solve the problems of extended construction period, inconvenience, extended construction period, etc., and achieve the effect of low cost, delayed degradation, and improved anti-seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

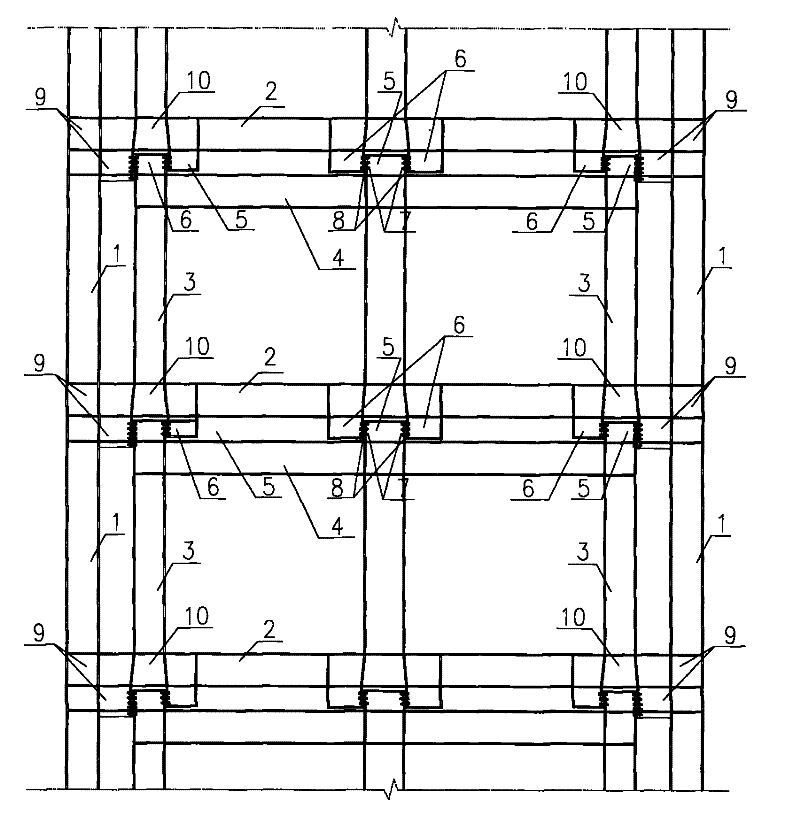

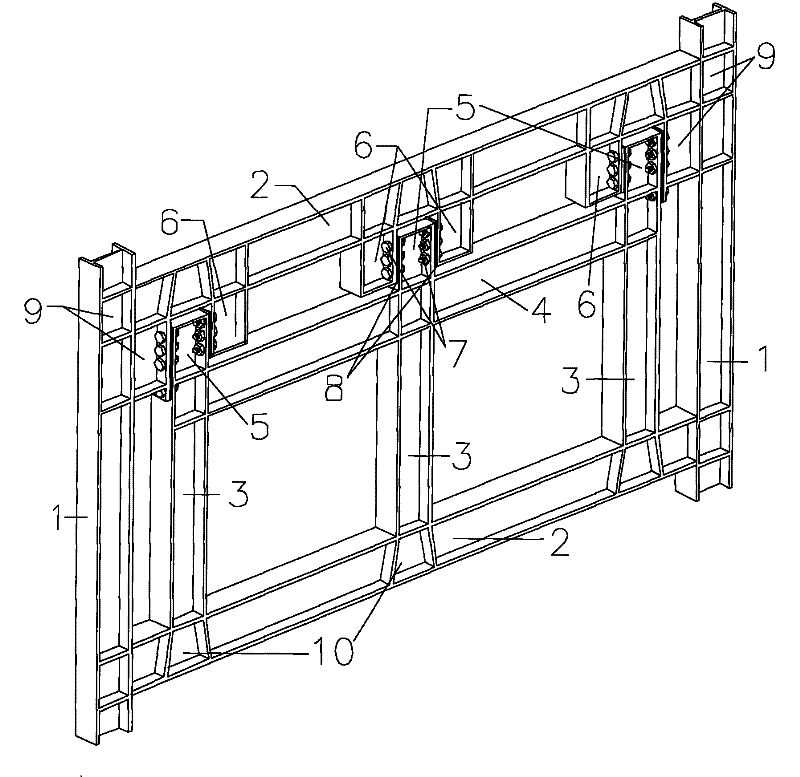

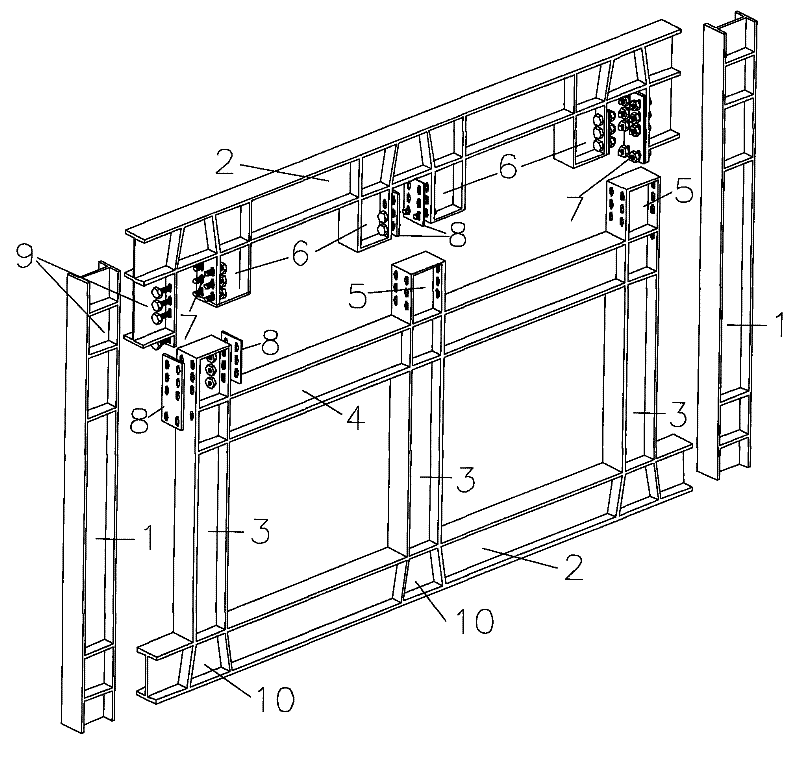

[0016] The present invention proposes the structure of connecting nodes through beams and supports, so that the embedded small frame support allows vertical displacement of the steel beam, so that the vertical load will not be transmitted to the support, and the embedded small frame support does not participate in bearing the vertical load; The support and the steel beam are in close contact in the horizontal direction, and there is no horizontal relative slippage. When the steel frame moves sideways under the action of a horizontal earthquake, the support point also moves horizontally at the same time. The support participates in bearing the horizontal force and plays an anti-seismic role. .

[0017] The purpose and effects of the present invention will become more apparent by describing the present invention in detail below with reference to the accompanying drawings.

[0018] As shown in the figure, the gravity-free embedded small frame seismic structure of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com