Set treatment device of sludge drying

A complete set of treatment and sludge drying technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of inability to achieve continuous sludge drying, tail gas treatment, and pollution of valuable components, and achieve high cost performance , simple structure, good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

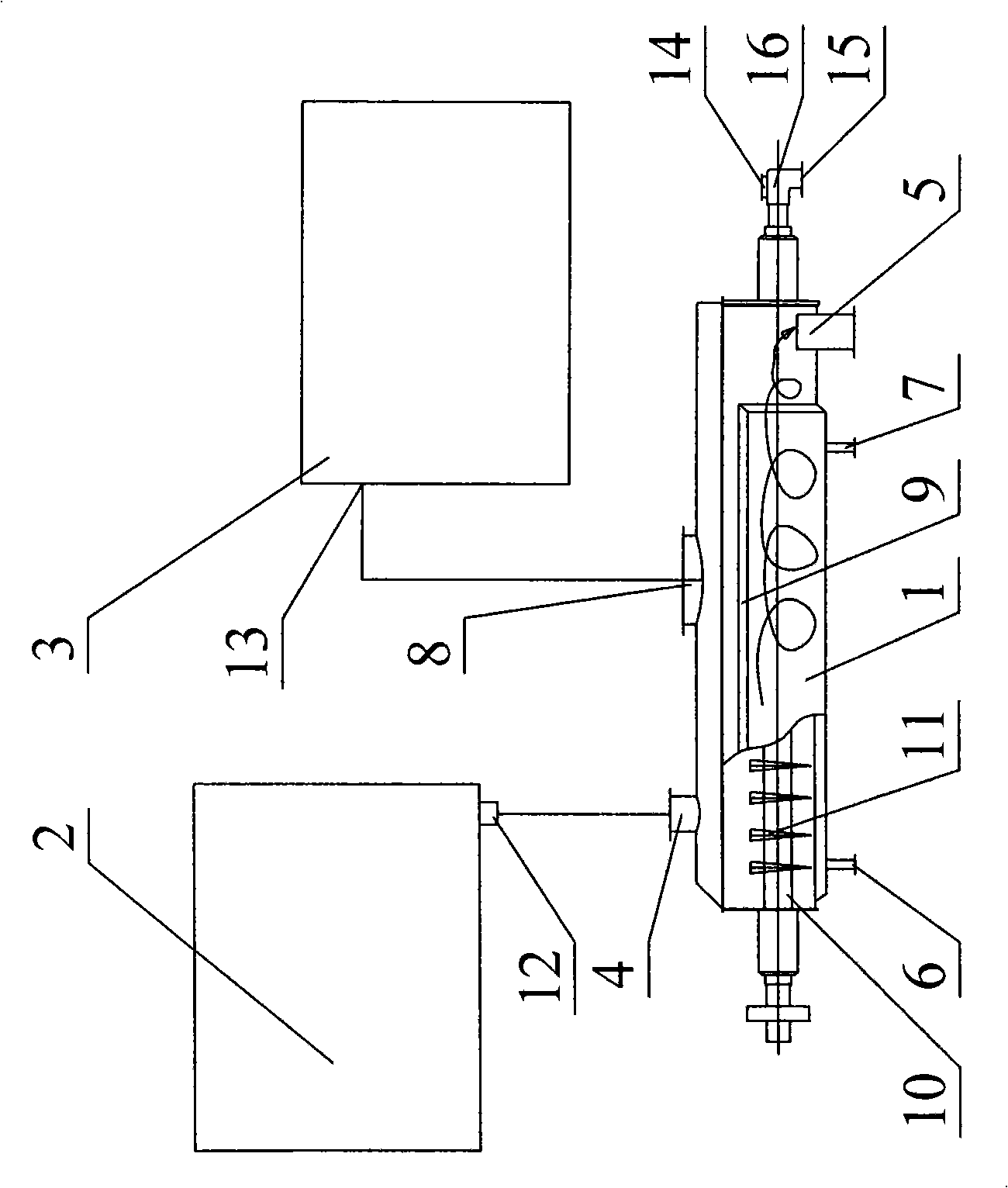

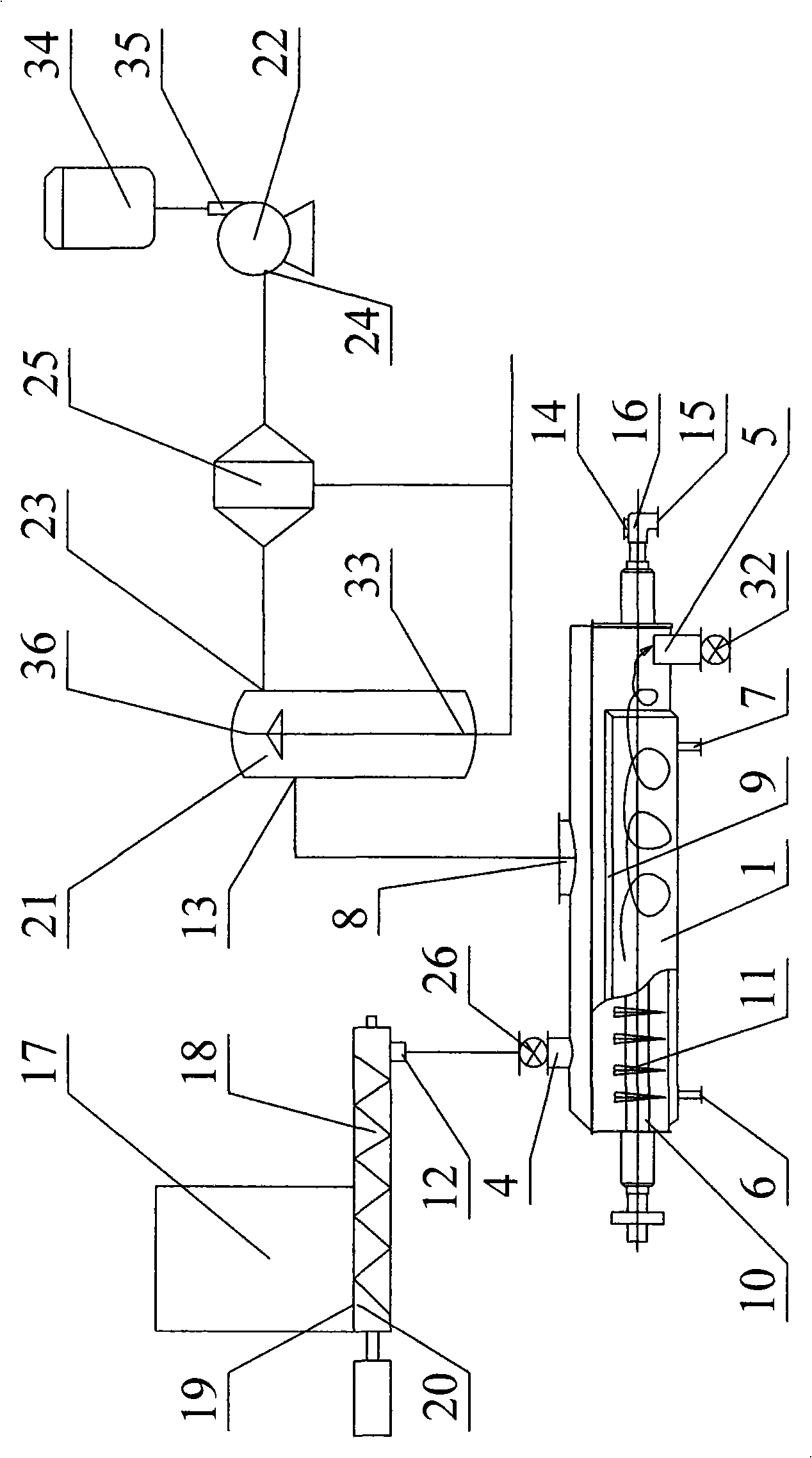

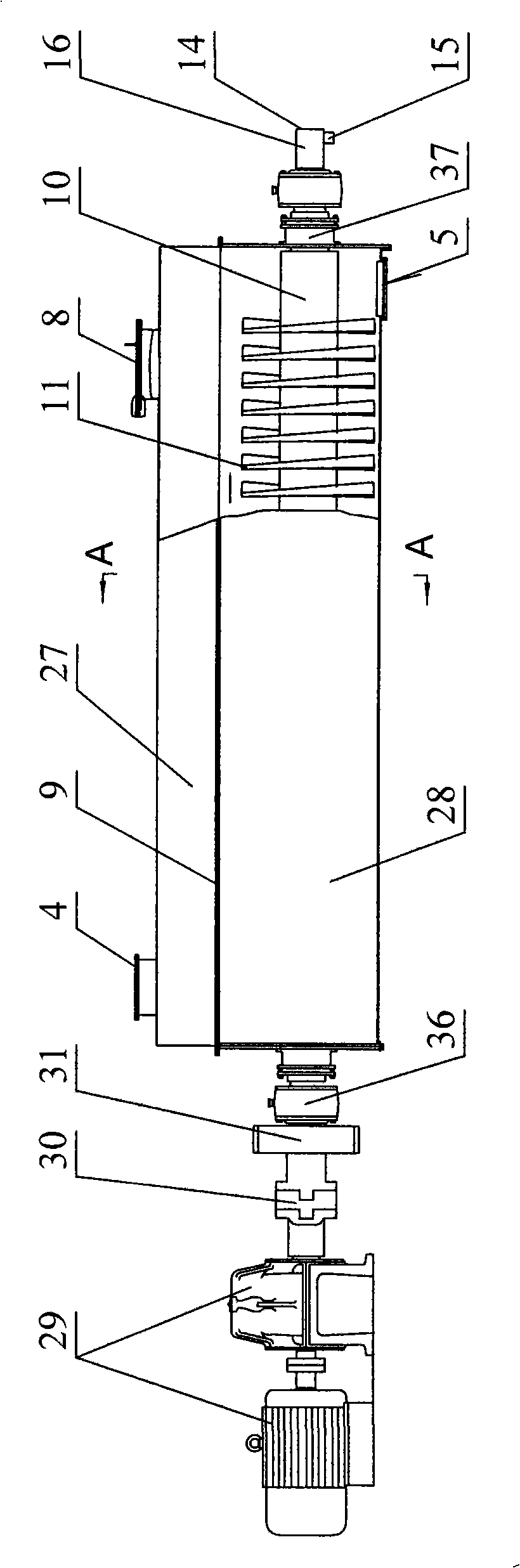

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0017] Such as Figure 1 to Figure 5 As shown, a complete set of sludge drying treatment device includes a paddle-type sludge dryer 1, a storage feeding device 2 and an exhaust gas purification treatment device 3. The paddle-type sludge dryer 1 includes a 4 and the upper cover 27 of the exhaust gas outlet 8 and a lower casing 28 with a discharge port 5 are connected to form a cylindrical body 9, and the cross-sectional shape of the lower casing 28 is W-shaped. Four hollow shafts 10 connected to the power transmission device 29 are installed side by side in the cylinder 9, and a group of hollow paddles 11 distributed along the axial direction are respectively installed on each hollow shaft 10, wherein the power installed on one side of the cylinder 9 The transmission device 29 includes a motor and a reducer, which are connected to the hollow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com