Evaporative cooling propulsion motor

A technology of evaporative cooling and electric motors, which is applied in the field of electric motors, can solve the problems of difficult to further improve the performance of electric motors, complex structure of electric motors, uneven cooling, etc., and achieve important economic and social benefits, large potential volume and mass output torque, Reduce the effect of uneven heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described as follows in conjunction with accompanying drawing and embodiment:

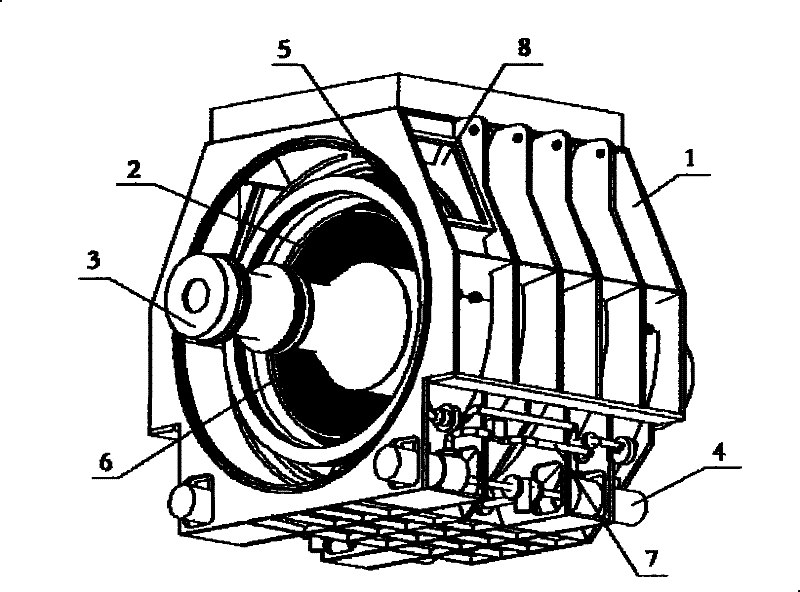

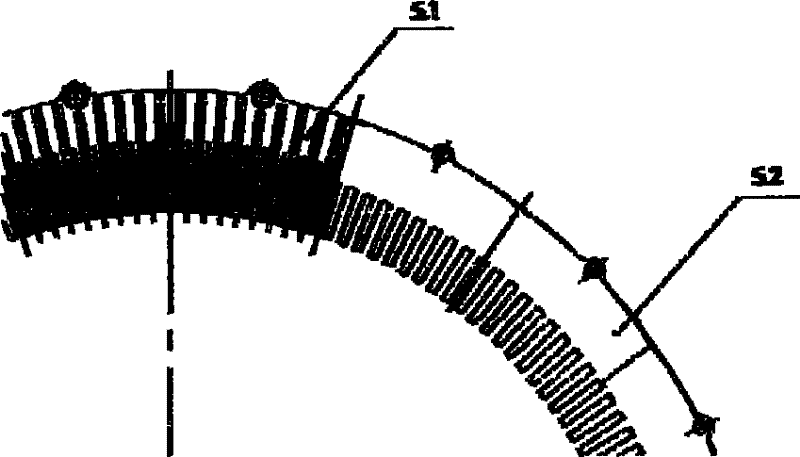

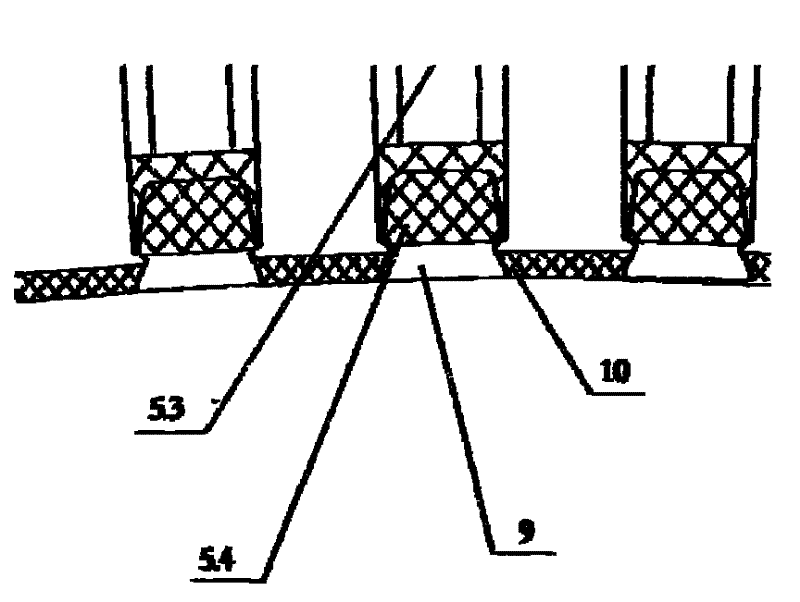

[0033] Such as Figure 1-10 Shown: a kind of evaporative cooling propulsion motor of the present invention, it has a machine base 1, stator 2, rotor 3 and cooling system 4; Described cooling system comprises stator core and winding linear part cooling circuit 5: rotor and stator winding Cooling circulation loop 6: cooling medium liquid circulation loop 7; cooling medium vapor-liquid two-phase loop 8. The cooling circuit 5 of the stator core and the straight line part of the winding has a solid tooth pressure plate 5.2 of an integral solid structure for preventing the cooling medium liquid from passing through, and a hollow tooth of a hollow tooth pressure plate structure that can overflow when the liquid is filled higher than the winding Pressure plate 5.1: There is a liquid-passing groove plate 5.3, a liquid blocking block 5.4, and a ring rib 5.5 on the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com