Optical device assembly system and method for fixing optical elements

A technology for optical components and assembly systems, applied in the direction of optical components, optics, installation, etc., can solve problems affecting the adjustment of optical components, damage to optical components, and limit the use range, etc., to ensure adjustment accuracy, small defect rate after welding, and avoid Effects of heat damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained and illustrated below in conjunction with the accompanying drawings.

[0036] As an embodiment of the present invention, an optical device assembly system includes an optical element fixing device and an adjustment device for adjusting the position of each optical element, the optical element fixing device includes a control module and is electrically connected to the control module The solder filling device and two temperature control rods are used to melt the solder, and the temperature of the temperature control rods is controlled and adjusted by the control module in the adjustment device.

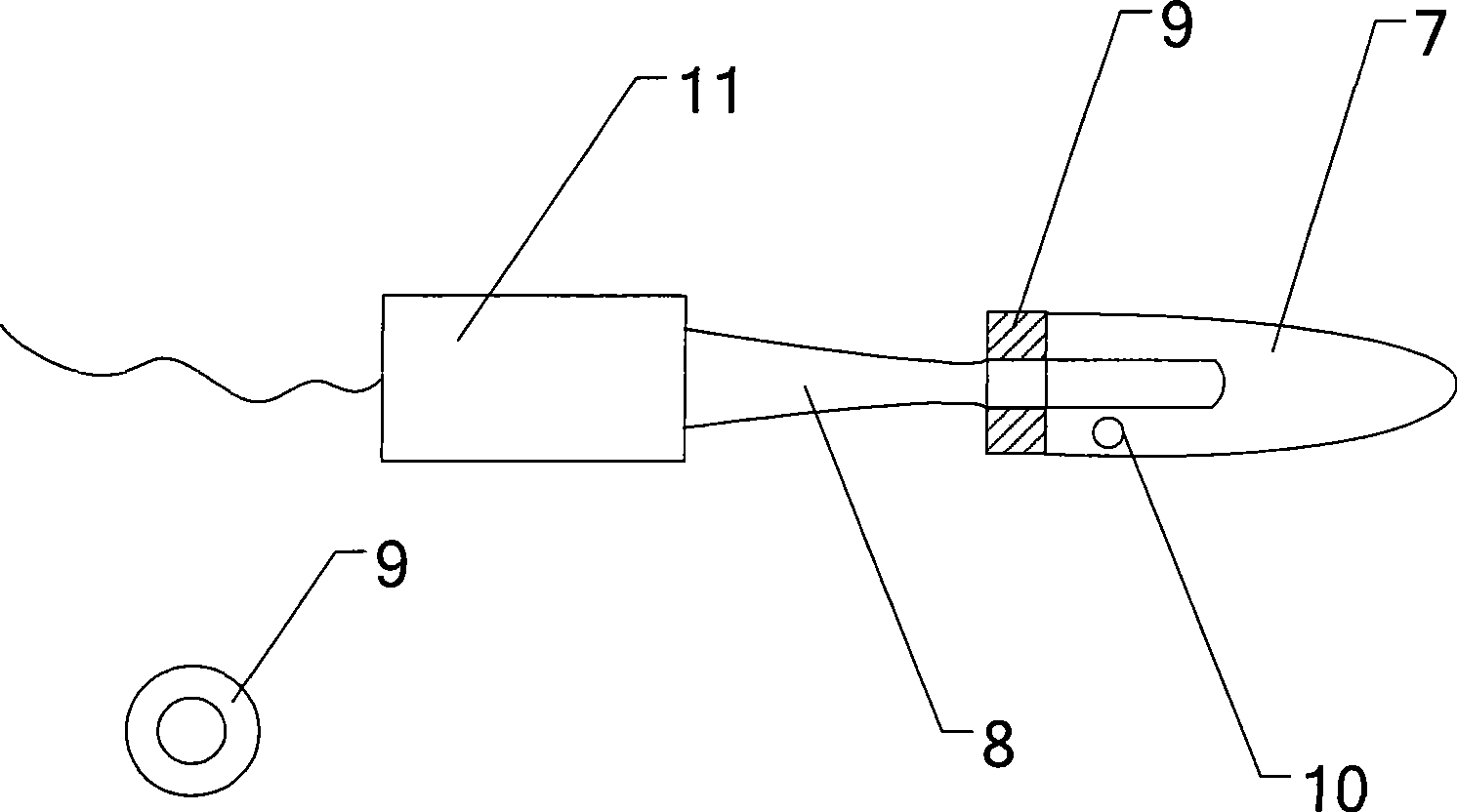

[0037] As an example, figure 1 A section structure of a temperature control rod is given, including a metal cover 7 , a ceramic heating rod 8 , a semiconductor cooling chip (TEC) 9 , a temperature sensor 10 and a handle 11 . The metal cover 7 is set on the front end of the ceramic heating rod 8, and a temperature sensor 10 electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com