Adjustable swing-type tuned mass damper

A tuned mass damping, swinging technology, applied in the field of building structural engineering and civil structural engineering, can solve the problems of TMD imbalance, no installation space, reduced expected vibration damping effect, etc., to achieve large span, reduced vibration, and small thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

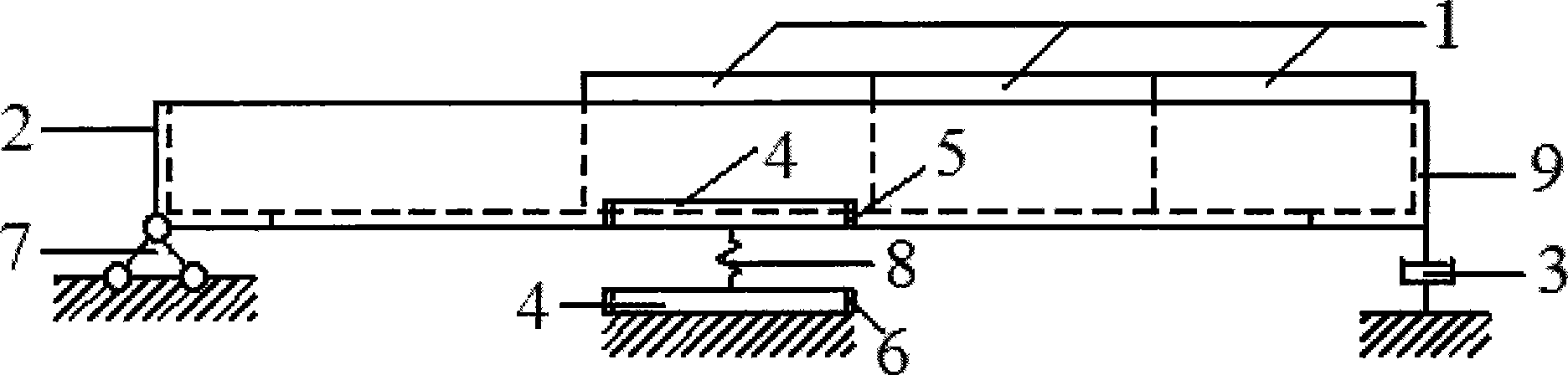

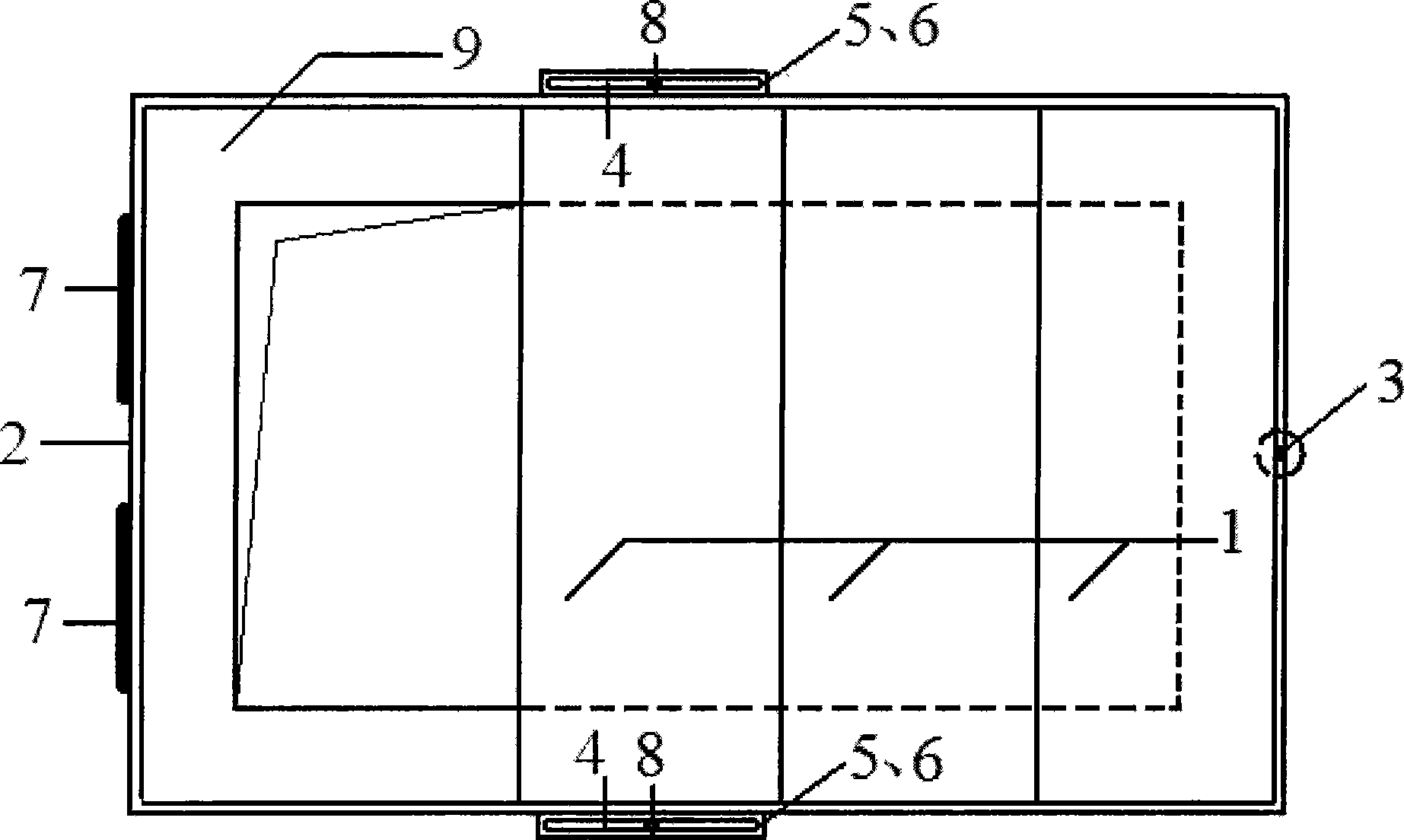

[0026] Such as figure 1 , figure 2 As shown, the base 2 of the adjustable oscillating tuned mass damper APTMD is a structural form of a rectangular steel frame 9 formed by welding or bolting L-shaped cross-section steel (or bolting channel-shaped steel). The mass block 1 is a steel block (or other metal materials such as cast iron), which is arranged on a local area (or the entire area) of the base 2 by means of bolt connection, and the quantity and position of the mass block 1 can be changed as required. A frame at one end in the length direction of the base 2 is provided with a hinge support 7 to be connected to the floor, the connection between the hinge support 7 and the frame and the embedded parts of the floor is welded, and the frame at the other end is provided with a damper 3 to be connected with the floor. The connection between the damper 3 and the frame and the embedded parts of the floor adopts bolt connection. Frame connectors 5 are respectively welded near th...

Embodiment 2

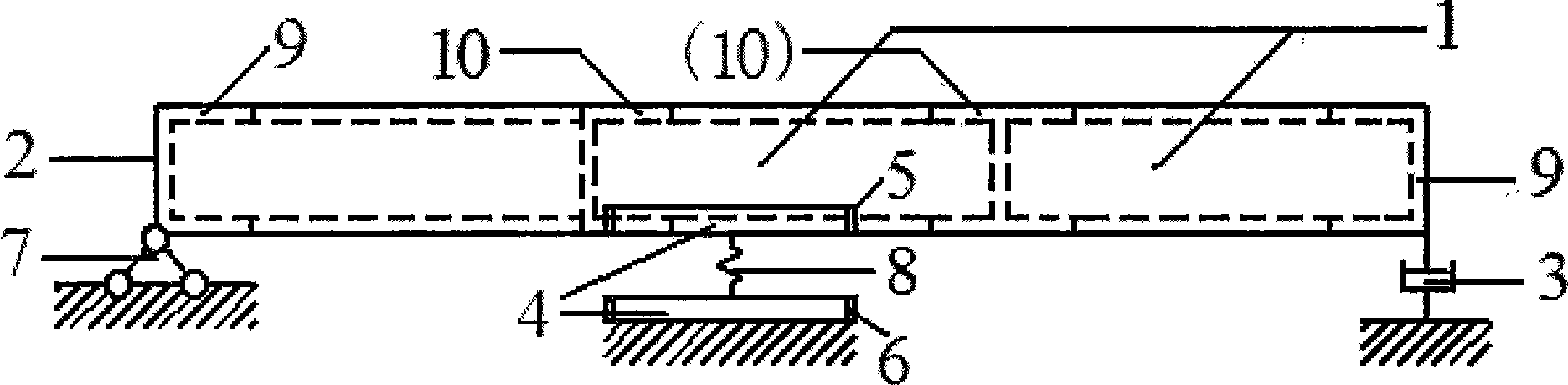

[0028] Such as image 3 , Figure 4 As shown, the base 2 of the adjustable oscillating tuned mass damper APTMD is a structural form connected by a rectangular steel frame 9 and an inner frame 10, the frame 9 is made of channel-shaped section steel, and the inner frame 10 is made of channel-shaped or H-shaped section Steel (the inner frame 10 indicated by the number in the brackets in the figure indicates that when the mass block 1 is set in a large range, the quantity of the inner frame 10 should be increased in this range to divide the mass block 1), and the connection method with the frame 9 is welding or bolted connection; the mass block 1 is a concrete slab poured on the base 2 in a partial range (or the entire range) by using concrete with high gravity density such as counterweight concrete and steel slag concrete. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com