Method for purifying dimethylchlorosilane by extraction and distillation

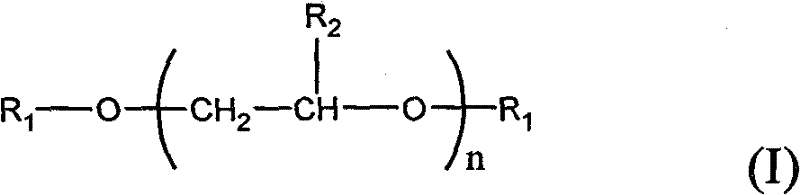

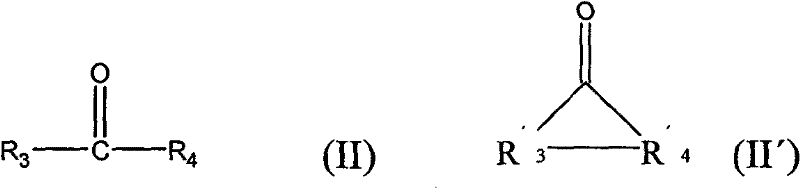

A technology of dimethylchlorosilane and methylchlorosilane, applied in chemical instruments and methods, silicon organic compounds, compounds of group 4/14 elements of the periodic table, etc., can solve low-boiling mixtures that cannot be directly applied to organosilicon Separation and purification and other issues, to achieve the effect of easy separation, easy distillation and separation, and increased relative volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a set of tower kettle volume 1m 3 1. In a batch rectification device with 80 theoretical plates, add 200kg of low boiling mixture to the tower kettle, and continuously add the extractant n-butyl butyrate at a speed of 3kg / min from the top of the tower. The boiling point of n-butyl butyrate is It is 164°C; the total amount of extractant added is 720kg. The rectification tower is controlled at normal pressure, and the extraction rate of fractions is 1-1.5kg / min. The entire distillation process is followed by gas chromatography, and fractions are cut according to changes in the composition of the overhead distillate. When the rectification of the low-boiling mixture is completed or the extractant fraction appears at the top of the tower, the rectification is ended, and the tank of the cooling tower is cooled to normal temperature, and the extractant can be directly reused.

[0037] The gas chromatographic detection results of each fraction are as follows:

[0038] ...

Embodiment 2

[0044] Extractant is diethylene glycol dimethyl ether, and boiling point is 162 ℃, and other is identical with embodiment 1, and the gas chromatography detection result of each cut is as follows:

[0045]

Embodiment 3

[0047] Extractant is dibutyl phthalate, and boiling point is 340 ℃, and other is identical with embodiment 1, and the gas chromatography detection result of each cut is as follows:

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com