Polynutrient biologic fertilization fertilizer and production method thereof

A production method and flushing fertilization technology, applied to the flushing fertilization production method and the field of flushing fertilization, can solve problems such as difficult large-scale batch production, increased soil diseases, and large site occupation, and achieve the expansion of application range and product quality. The effect of improving and reducing the cost of treatment and disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

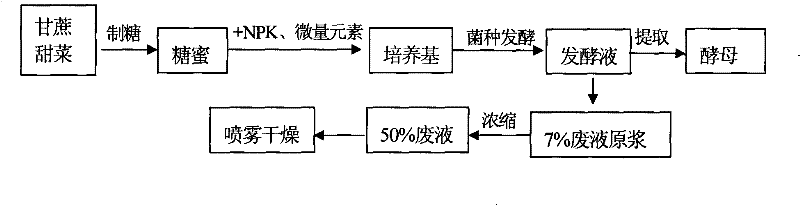

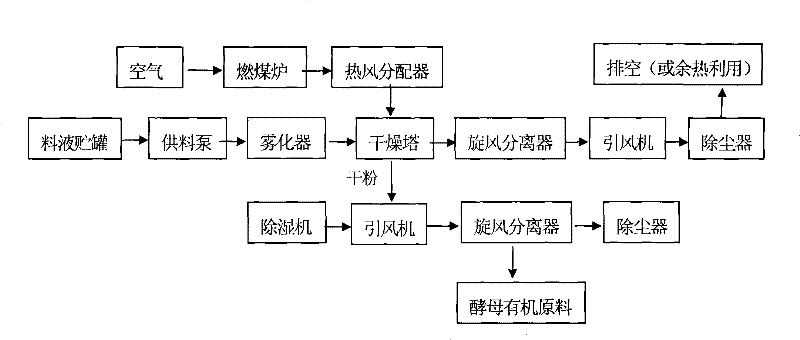

[0029] Concentrate the waste liquid puree of the fermentation liquid after extracting the yeast. The concentration of the waste liquid puree is about 7%. Brown powder yeast organic raw material.

[0030] The basic properties of the powdery yeast organic material after spray drying are shown in Table 1.

[0031] Table 1 Basic character of powdery yeast organic raw material

[0032]

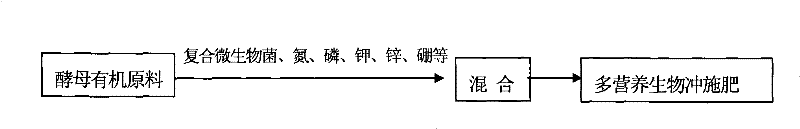

[0033] Bacillus subtilis and Bacillus mucilaginosus are fermented and produced separately by fermentation equipment, and the fermented bacterial liquid is respectively used with 80 mesh rice husk powder according to the ratio of bacterial liquid: rice husk powder = 1:3 Adsorption, the two adsorbed single bacterial agents are mixed according to the ratio of 1:2, and crushed to 80 mesh;

[0034] Carry out accurate batching according to the raw material ratio of Table 2 in the mixer that capacity is 1000 kilograms. N in urea is 46%; potassium source is K in potassium sulfate 2 O is 50% or Potas...

Embodiment 2

[0041] In the preparation of the composite microbial agent, the mixing ratio of Bacillus subtilis and Bacillus mucilaginosus after fermentation is 1:2.5, and after mixing, they are pulverized to 100 mesh. The fineness of the rice husk powder is 100 mesh, and the adsorption ratio of the bacterial agent to the rice husk powder is 1:5.

[0042] The addition ratio of yeast organic raw material is 50%, the addition ratio of bacterial agent is 10%, the addition ratio of urea is 25%, the addition ratio of potassium sulfate is 7%, zinc sulfate is 2%, borax is 1%, ferrous sulfate 2% for magnesium sulfate and 3% for magnesium sulfate. Others are the same as embodiment 1.

Embodiment 3

[0044] In the preparation of the composite microbial agent, the mixing ratio of Bacillus subtilis and Bacillus mucilaginosus after fermentation is 1:1.5, and they are pulverized to 120 mesh after mixing. The fineness of the rice husk powder is 120 mesh, and the adsorption ratio of the bacterial agent to the rice husk powder is 1:4.

[0045] The addition ratio of yeast organic raw material is 31%, the addition ratio of bacterial agent is 5%, the addition ratio of urea is 40%, the addition ratio of potassium sulfate is 20%, zinc sulfate is 1.5%, borax is 1%, ferrous sulfate 1% for magnesium sulfate and 0.5% for magnesium sulfate. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com