Preparation method for realizing micro-encapsulation of core material by acoustic surface wave atomizer

A surface acoustic wave and microencapsulation technology, which is applied in the field of preparation in the field of microencapsulation technology, can solve the problems of complex manufacturing process, expensive equipment, low production efficiency of microcapsules, etc., and achieves the effect of improving efficiency and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

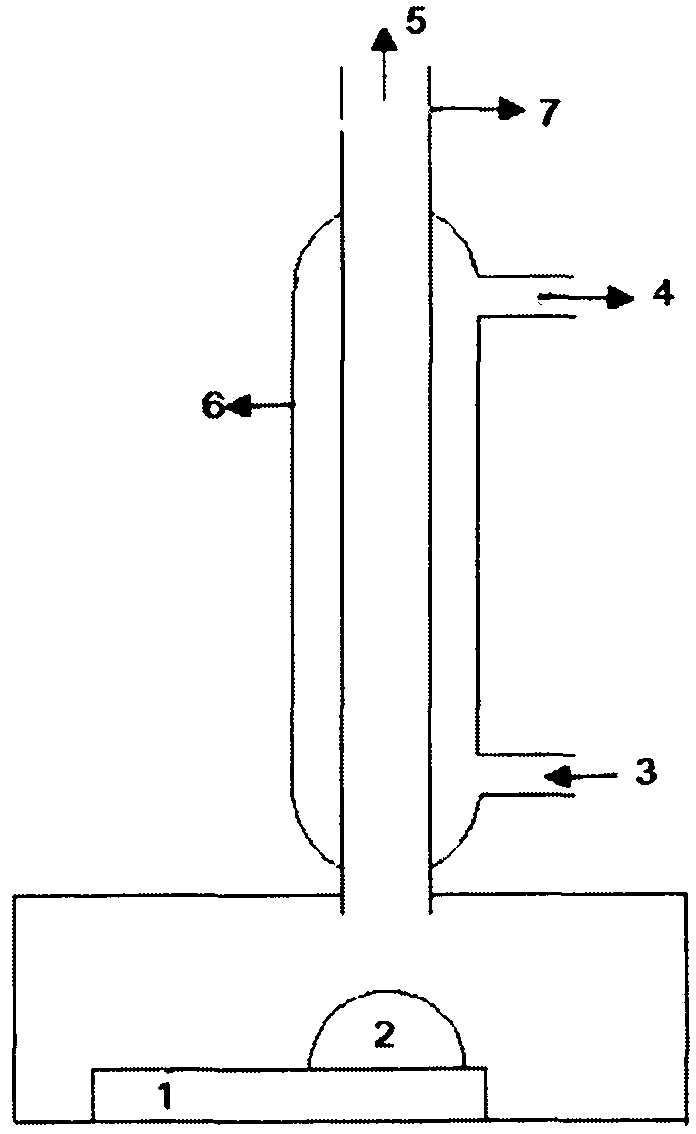

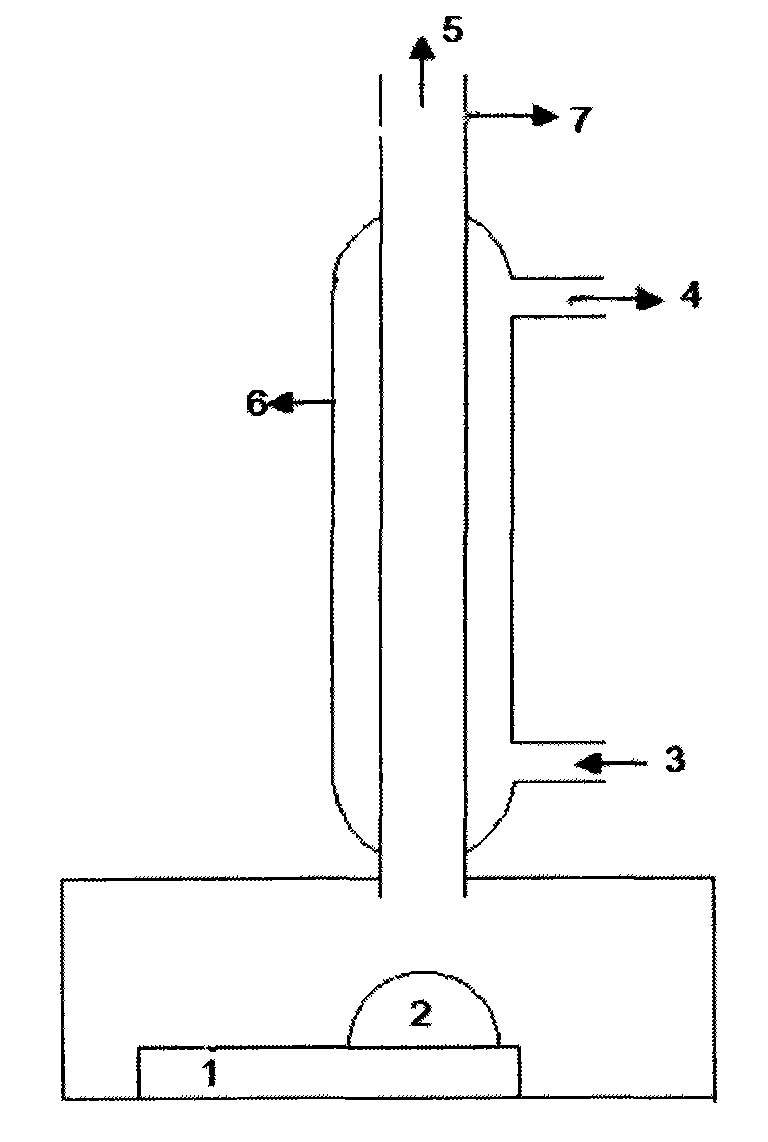

Image

Examples

Embodiment 1

[0019] The preparation process of the specific embodiment is as follows:

[0020] Step 1, configure the core material emulsion and coagulant:

[0021] Configuration of sesame oil emulsion: First, configure 100ml of sodium alginate aqueous solution with a mass fraction of 3%, then configure 100ml of a mixed aqueous solution with a mass fraction of 0.2% monoglyceride and a mass fraction of 0.4% Tween-80, and then mix 100ml of Sodium alginate aqueous solution, 100ml mixed emulsifier solution and 100ml water were poured into a beaker and mixed and stirred. After stirring evenly, put it in a constant temperature water bath at 50℃~60℃. Finally, under constant stirring of the mixed solution, slowly add 20ml of sesame oil core material. After the jet is added, continue to stir until uniform, stop stirring, and the resulting mixed solution is the sesame oil emulsion;

[0022] Configuration of coagulant: calcium chloride aqueous solution with a mass fraction of 2%;

[0023] Step 2, by...

Embodiment 2

[0027] The preparation process is as follows:

[0028] Step 1, configure the core material emulsion and coagulant:

[0029] Configuration of sea buckthorn oil emulsion: first take 100ml of sea buckthorn oil, add 0.2 mg of vitamin E (VE) to sea buckthorn oil, stir well, then add 2.4 g of emulsifier S-170 and stir well to obtain sea buckthorn oil emulsion ;

[0030] Configuration of coagulant: first dissolve 5mg of gum arabic into a viscous solution with 100ml of water, then add 2.4mg of emulsifier S1570, 1mg of citric acid monoglyceride and 1mg of malt lake essence to the viscous solution, and stir until uniform , the condensate is obtained;

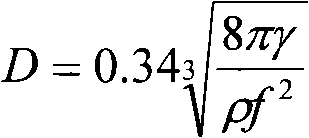

[0031] Step 2, by the formula D = 0.34 8 πγ ρ f 2 3 Obtain the resonant frequency of the SAW atomizer, where γ represents the surface tension of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com