Steam application technological process in the process for preparing the crystal cobalt chloride by cobalt chloride solution

A cobalt chloride and solution technology, applied in solution crystallization, chemical instruments and methods, cobalt halide and other directions, can solve problems such as energy waste and environmental pollution, and achieve the effects of reducing pollution, significant exhaust gas emissions, and obvious energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

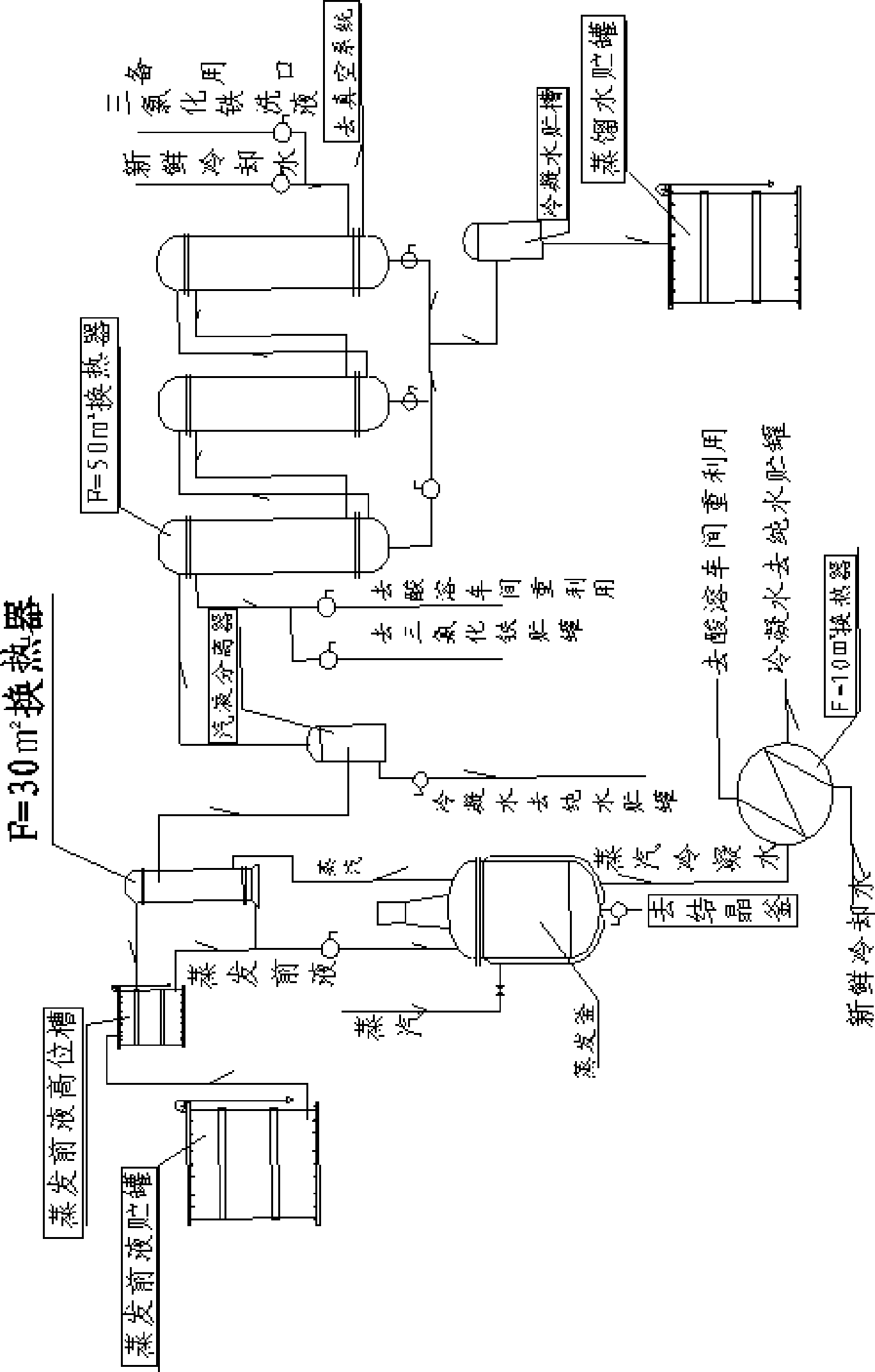

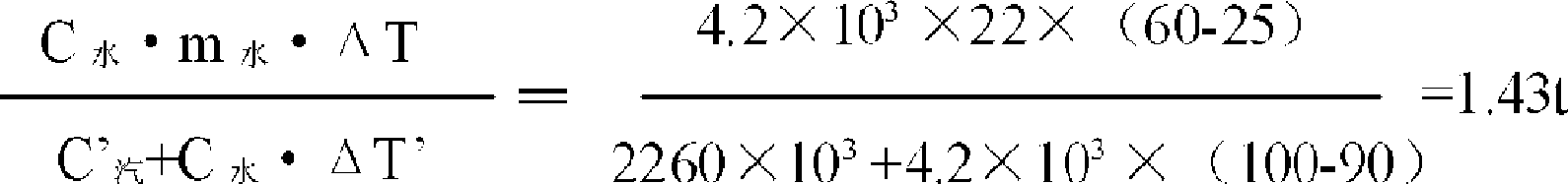

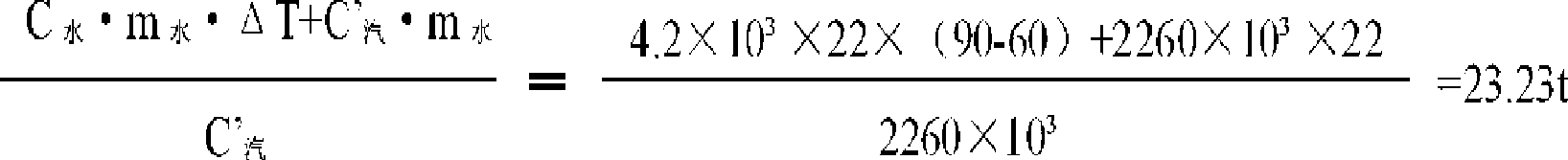

[0030] Such as figure 1 As shown, the present invention uses the cobalt chloride solution to prepare the process method of steam utilization in the crystalline cobalt chloride process, at first the cobalt chloride solution is pumped into the liquid head tank before evaporation from the pre-evaporation liquid storage tank, and uses the first heat exchange The steam in the device preheats the cobalt chloride solution in the liquid head tank before evaporation to 60°C, then puts the preheated cobalt chloride solution into the evaporation kettle, and feeds steam to cool the cobalt chloride solution in the evaporation kettle. The solution is heated, the vacuum degree of the evaporator is -0.07MPa, and the temperature is 85°C. After the evaporation is completed, the remaining cobalt chloride solution is put into the crystallization kettle to carry out the crystallization process; the steam condensate used for heating the cobalt chloride solution is then Enter the second heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com