Suction nozzle of cylindrical vacuum dust collector

A vacuum cleaner, cylindrical technology, applied in the direction of vacuum cleaners, suction nozzles, cleaning equipment, etc., can solve the problems of weakened suction performance of cleaning devices, weakened suction effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

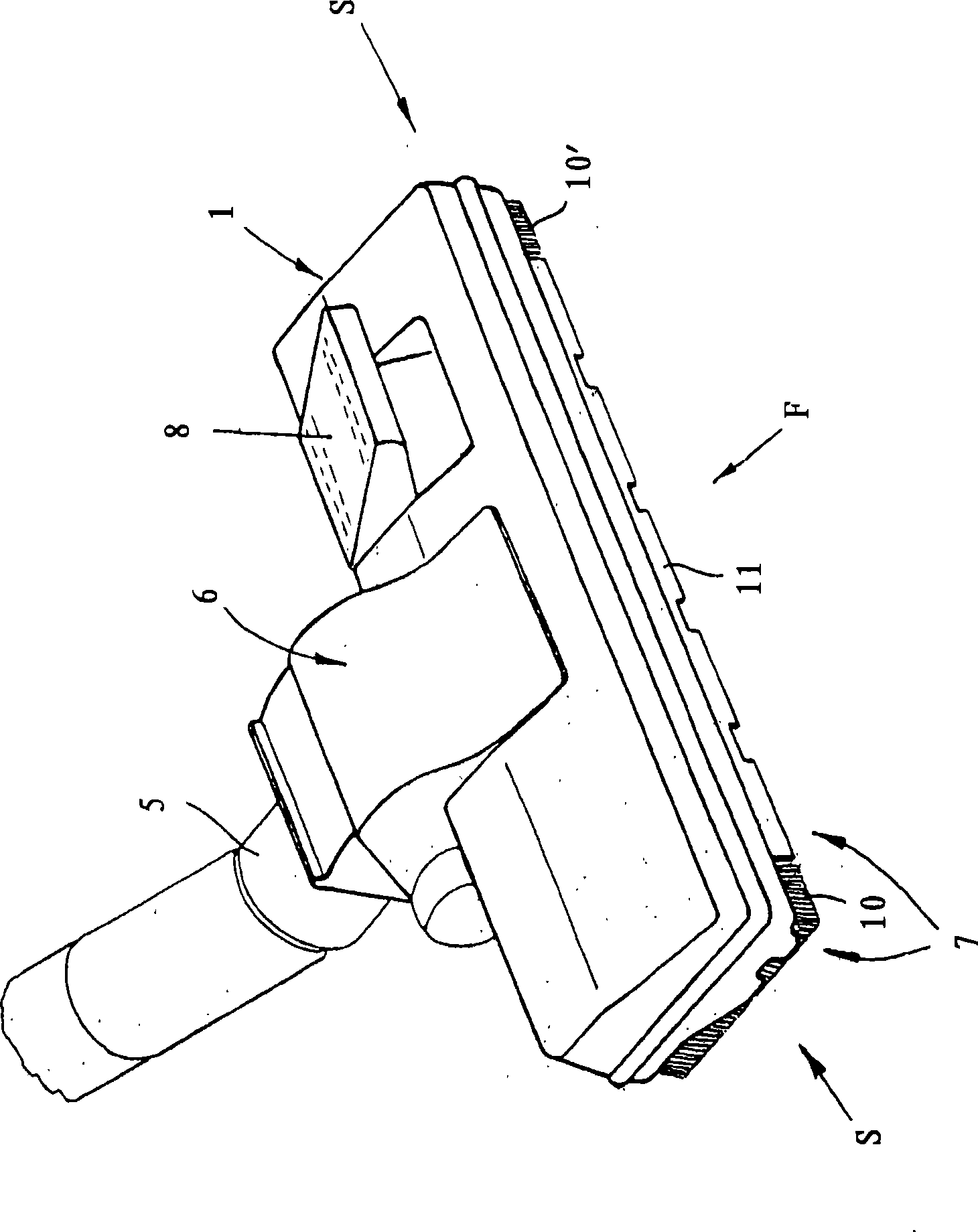

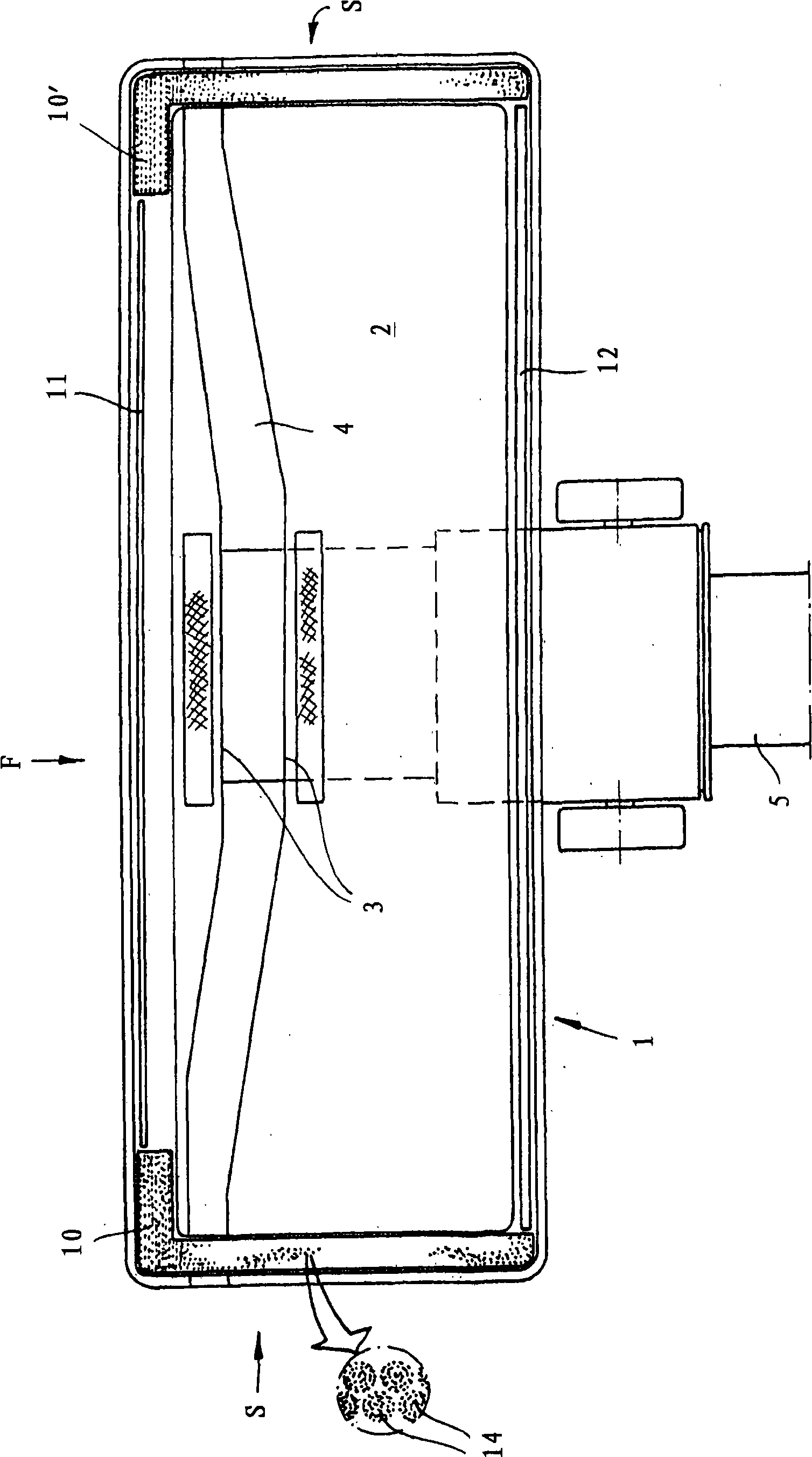

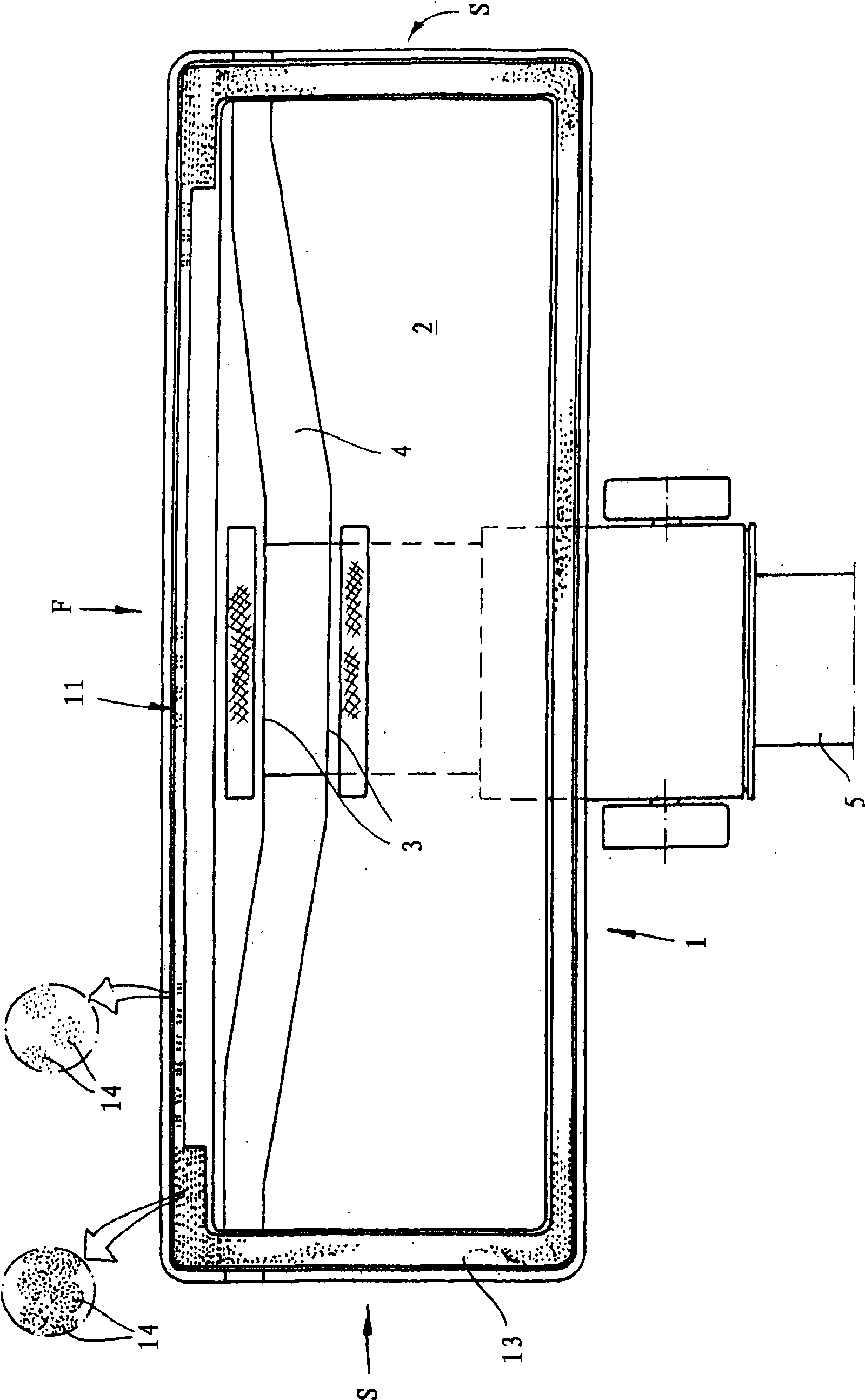

[0013] figure 1 Shows a nozzle that can be fitted to a cylinder vacuum cleaner with suction tube and suction hose. Its basic structure includes: a suction head 1 that is substantially rectangular in plan view; a bottom side sliding base 2 with a suction slot 4; The suction channel is rotatably attached to the suction head; and the extended support and seal 7 for vacuuming the smooth floor on the underside of the suction nozzle by means of a switch operable on the suction head 1 8 and by means of a support movably arranged in the suction head, the support and the seal can be actuated.

[0014] Utilize this support and sealing member 7 that protrudes on the floor side, for example constituted by bristle strips, a satisfactory gap can be formed between the bottom side suction edge 3 and the floor surface, preferably a gap of 5-10 mm, so that even coarse dirt Particles can also be removed from floors with this nozzle. In this case, the support and seal arranged parallel to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com