Surface-emitting laser array, optical scanning device, and image forming device

一种激光器阵列、表面发射的技术,应用在激光器、半导体激光器、光学等方向,能够解决激光器输出性能降低、可靠性下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

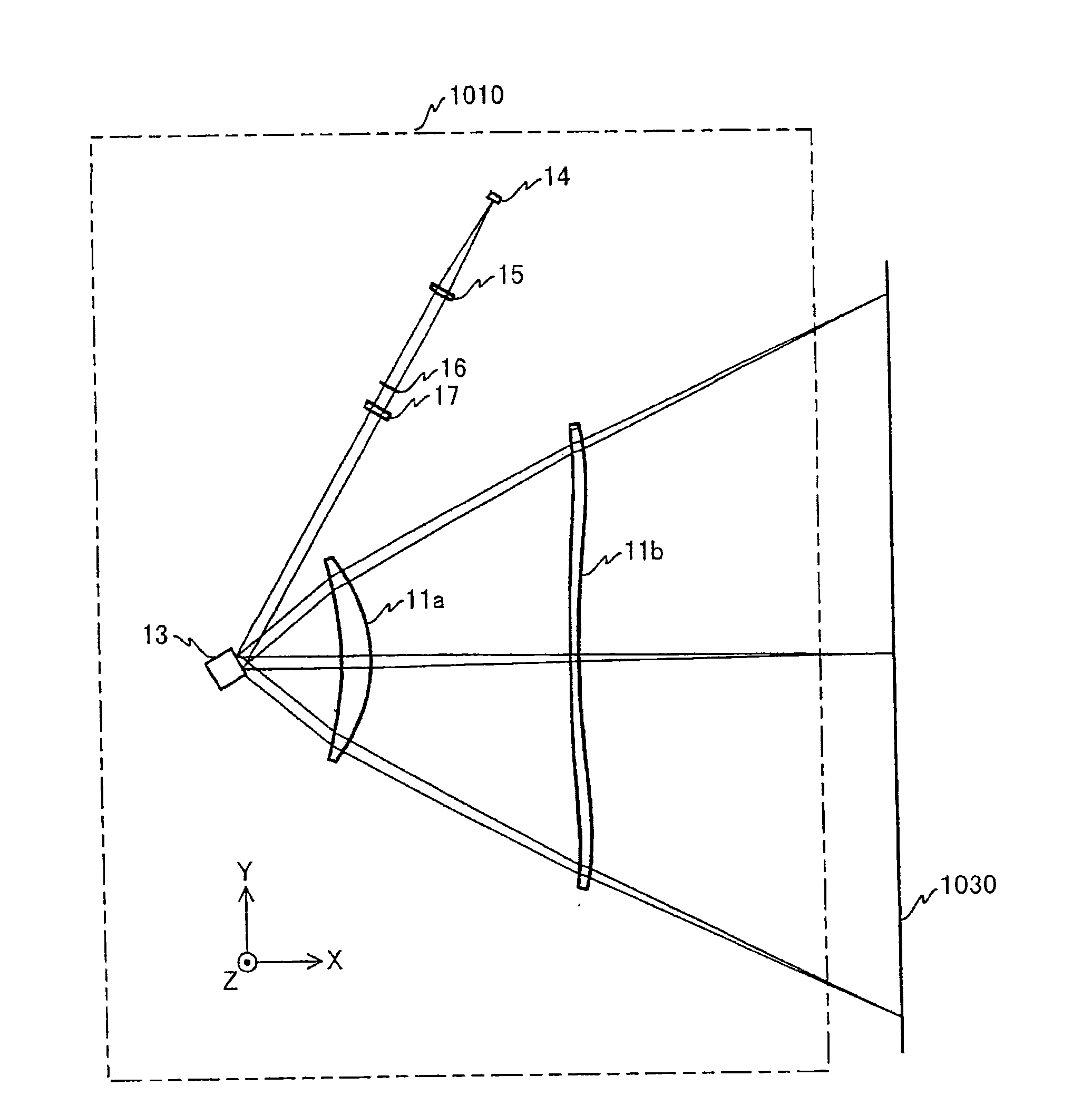

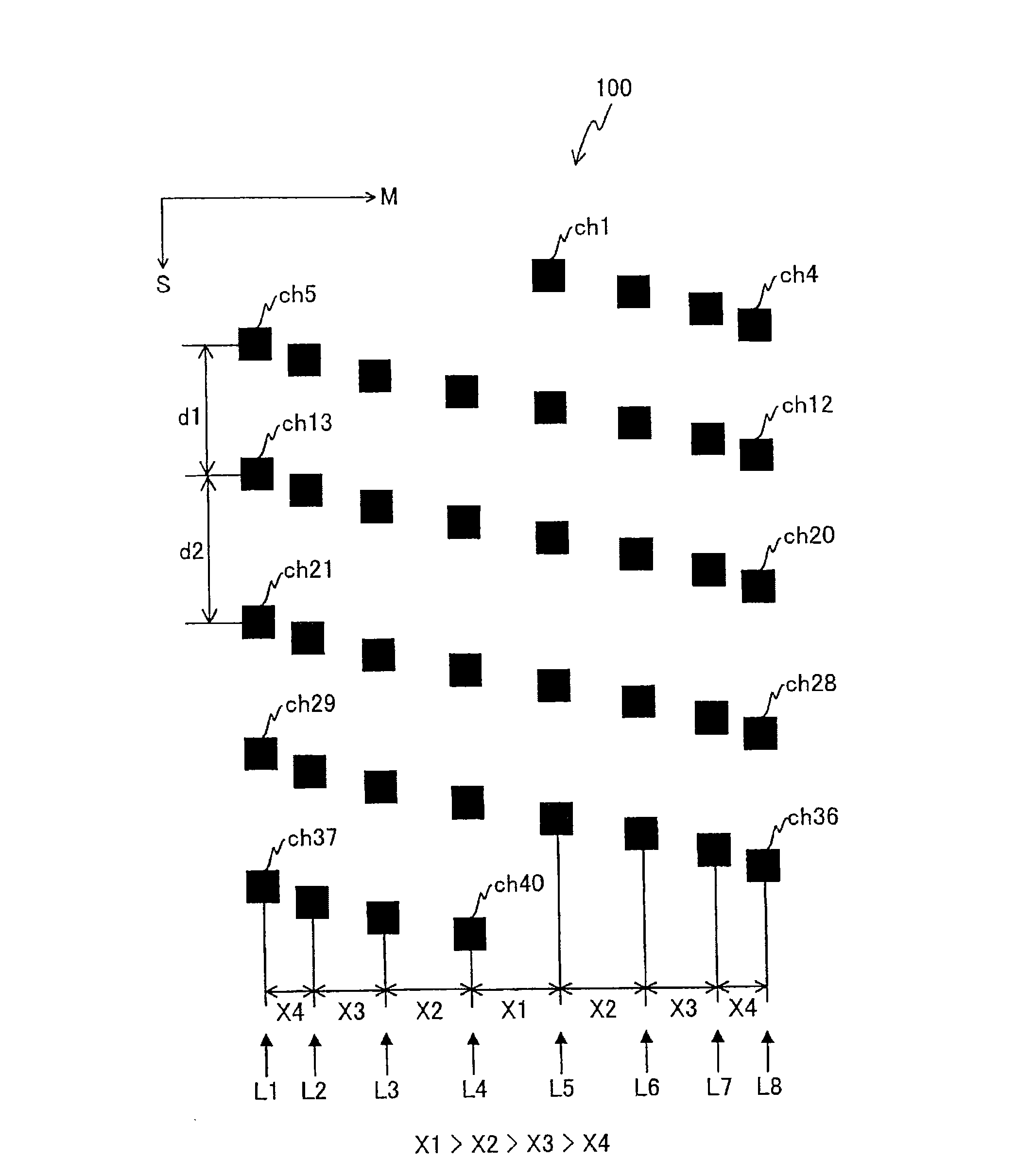

[0041] Various embodiments of the present invention will be described below with reference to these drawings.

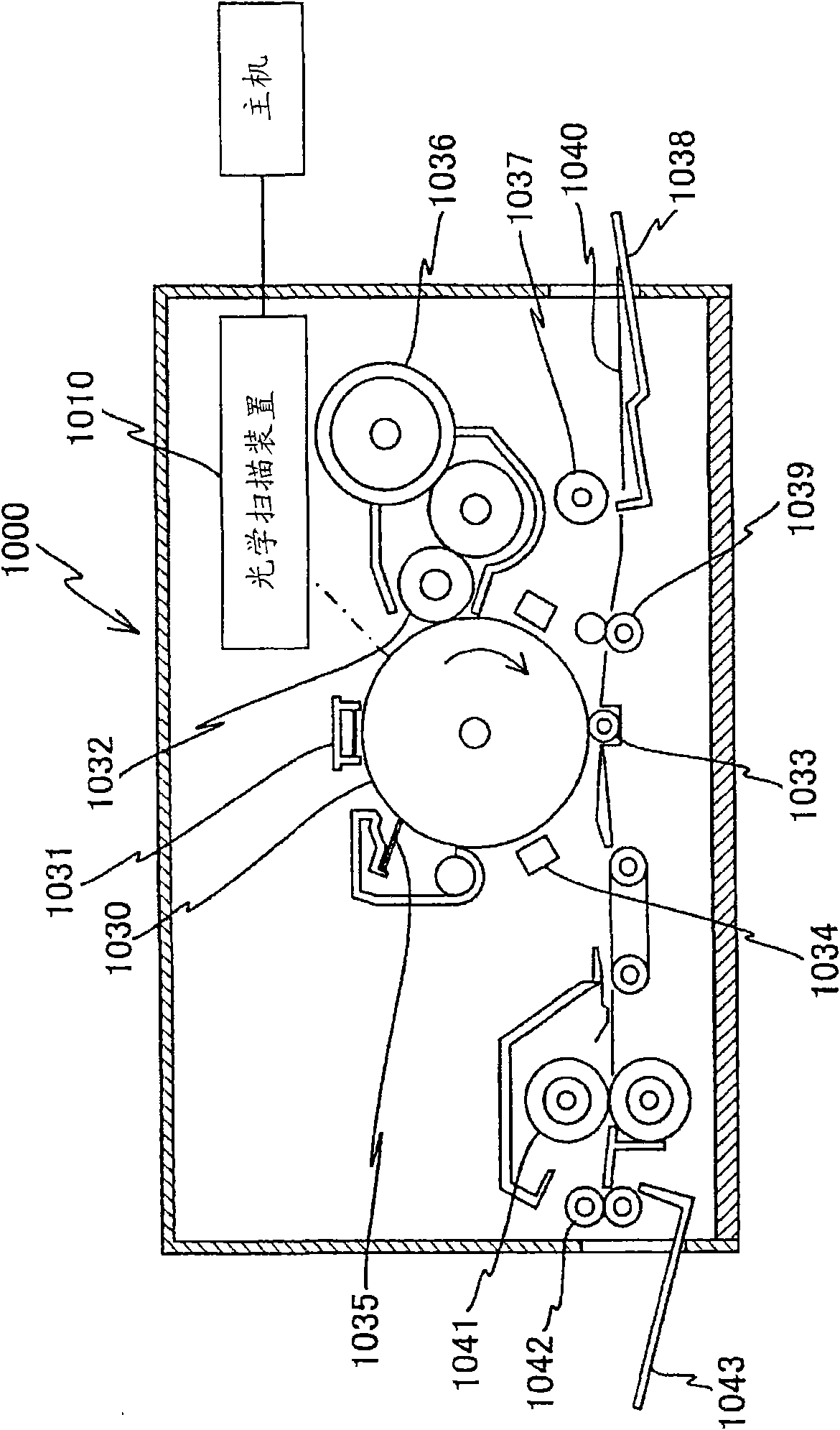

[0042] figure 1 The structure of a laser printer 1000 as an image forming apparatus in the embodiment of the present invention is shown. This laser printer 1000 includes an optical scanning device 1010, a photosensitive drum 1030, a charging device 1031, a developing roller 1032, a transfer charging device 1033, a discharging device 1034, a cleaning blade 1035, a toner cartridge 1036, a paper feeding roller 1037, a paper feeding Tray 1038 , Registration Roller Pair 1039 , Fixing Roller 1041 , Paper Out Roller 1042 , and Paper Out Tray 1043 .

[0043] A photosensitive layer is formed on the surface of the photosensitive drum 1030 . The surface of the photosensitive drum 1030 is the surface to be scanned. In this embodiment, the photosensitive drum 1032 is formed along the figure 1 Turn in the direction indicated by the arrow.

[0044] A charging device 1031 , a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com