Method for detecting dynamic specific oxygen utilization rate of activated sludge system

A technology of specific oxygen consumption rate and system dynamics, applied in the field of SBR technology, it can solve the problems of hysteresis and inability to provide online feedback, and achieve the effects of simple operation, high degree of automation and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

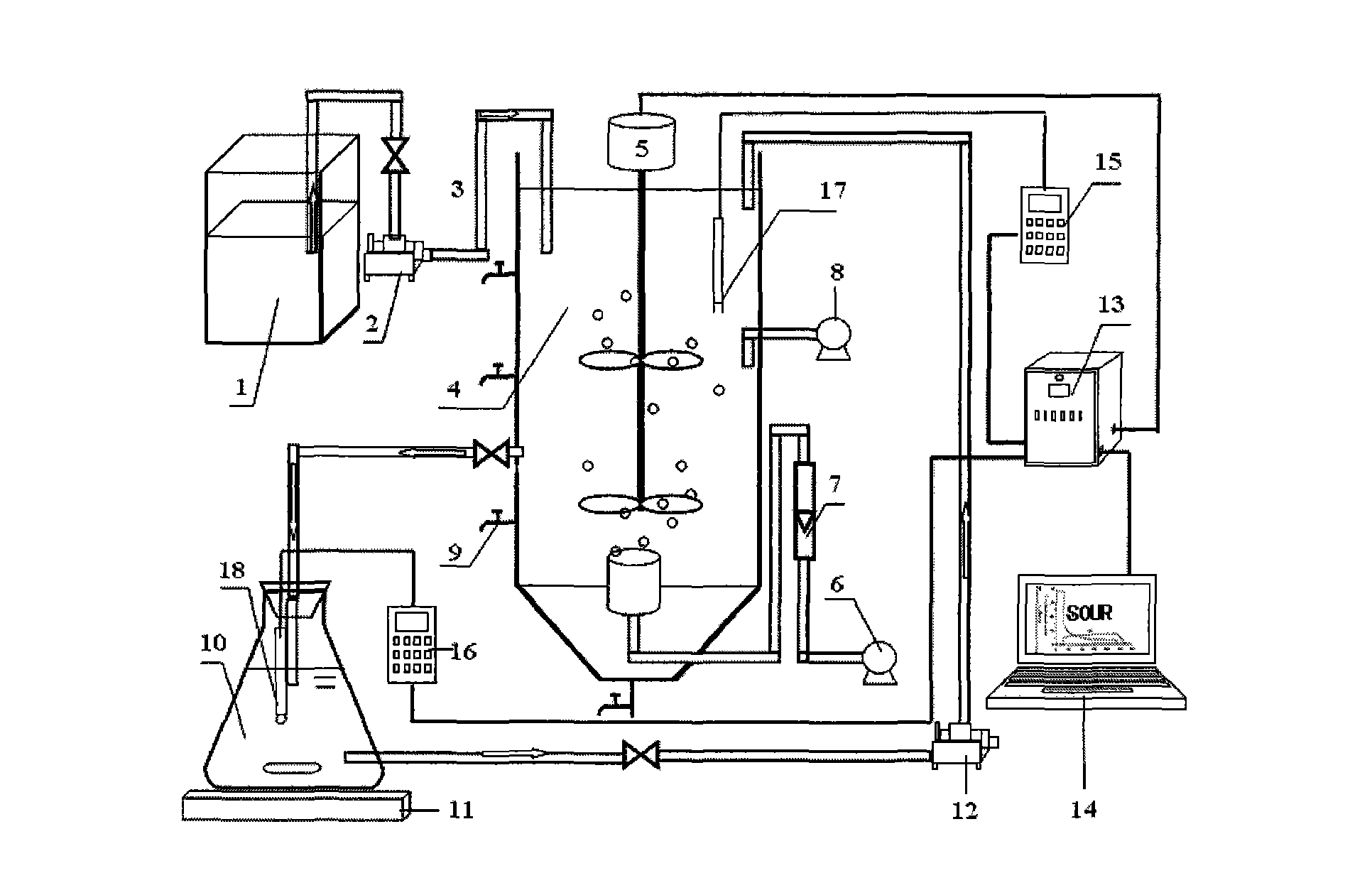

[0031] The reaction device adopted in this embodiment comprises a reactor system, a metering system and an automatic control system (such as figure 1 shown).

[0032] Reactor system: Domestic sewage is led to the water tank 1, lifted by the water pump 2, and enters the SBR reactor 4 through the water inlet pipe 3. The mixing of anoxic and anaerobic is done by stirrer 5. The aerobic oxygenation is completed by the air blower 6 through the microporous aeration head under the flow rate adjusted by the flow meter 7 , the carbon source required for denitrification is added by the dosing pump 8 , and the drainage is completed through the drain valve 9 .

[0033] The metering system includes a closed metering bottle 10, which is placed on a magnetic stirrer 11. When the system is running, the rotor of the magnetic stirrer keeps stirring to keep the sludge in a suspended state. The return pump 12 controls the return flow of the sludge to make the whole sludge The system is in a loop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com