PDC drilling property determination test device

A technology for testing devices and characteristics, applied in the direction of measuring devices, strength characteristics, mechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

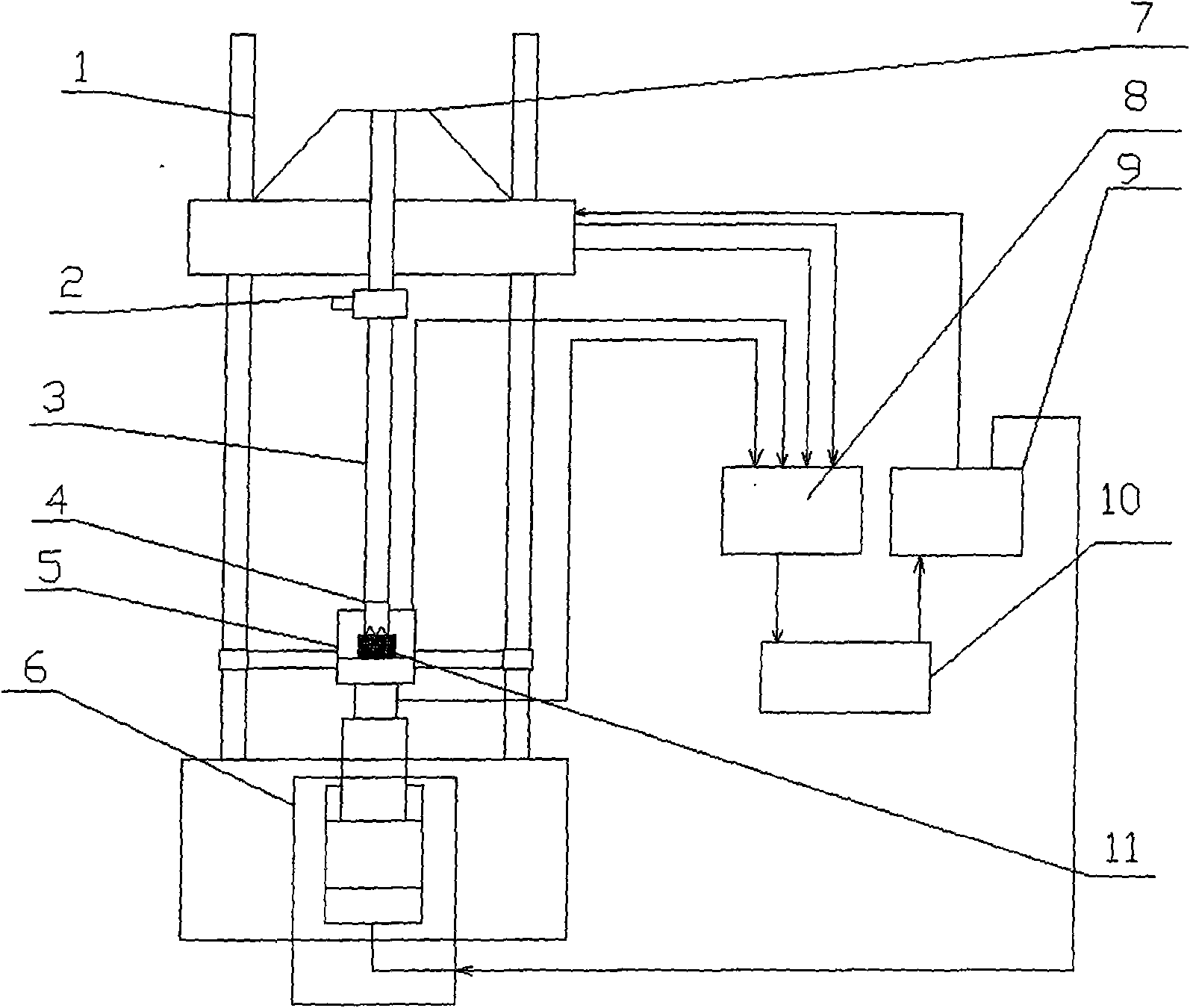

[0007] Refer to attached figure 1 , specific embodiments of the present invention will be described in detail.

[0008] exist figure 1 Among them, the simulated drill string 3, the simulated drill bit 4, the rock sample clamping system 5, the load loading system 6, and the rotating system 7 are installed on the frame 1; the torque sensor and the rotational speed sensor in the rotating system 7 communicate with the data acquisition through the shielded signal line. The displacement sensor in the rock sample clamping system 5 is connected to the data collector 8 through a shielded signal line, and the load sensor in the load loading system 6 is connected to the data collector 8 through a shielded signal line. In addition, the control lines output by the console 9 connected to the computer 10 can respectively control the starting of the motors in the load loading system 6 and the rotating system 7 .

[0009] In the experiment process of the present invention, the front end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com