Long-short pile composite foundation top-down construction method

A composite foundation and construction method technology, applied in the direction of foundation structure engineering, construction, etc., can solve the problems of short piles and soil stress lag, long piles, short piles and soil deformation uncoordinated, etc., to enhance the bearing capacity, improve the pile and soil The degree of synergy and the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

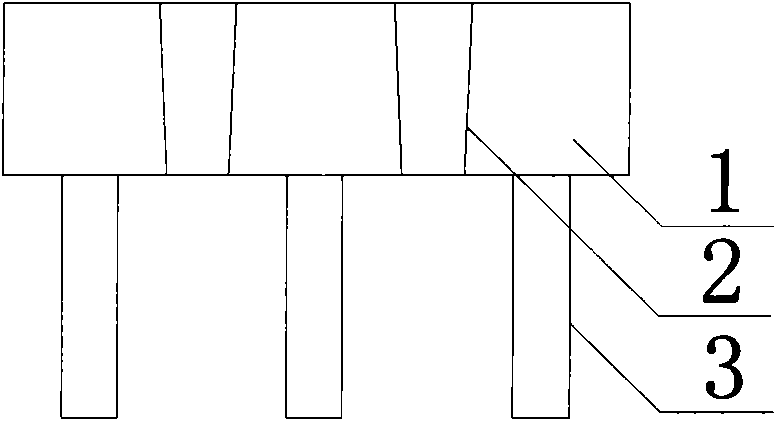

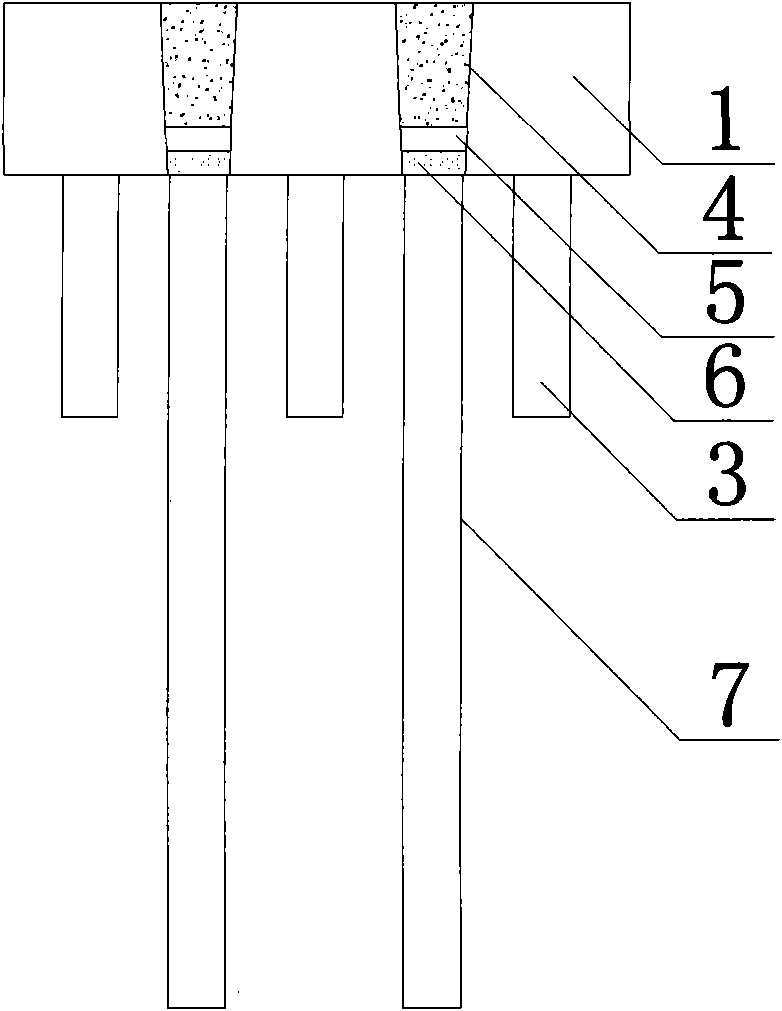

[0017] like figure 1 , figure 2 As shown, the construction steps of the long-short pile composite foundation reverse method construction method provided by the invention include:

[0018] a) The short pile 3 is constructed according to the design requirements, which is consistent with the traditional method;

[0019] b) Pouring and tamping the foundation floor, and reserve 7 holes for long piles during construction;

[0020] c) Construction of local superstructure building structures;

[0021] d) construction long pile 7;

[0022] e) Close the 7 pile holes of the long pile.

[0023] Among them, between the long piles and the foundation, crushed stones with a particle size of less than 2cm and coarse sand are laid for compaction. The sequence of closed pile holes is arranged according to the settlement difference of the upper building and the load distribution of the upper structure. The closed pile holes are made of C35 early-strength micro-expansion concrete 4 .

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com