Die adjusting mechanism

A technology for adjusting mechanisms and molds, applied to presses, manufacturing tools, etc., can solve problems such as high prices, simple, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

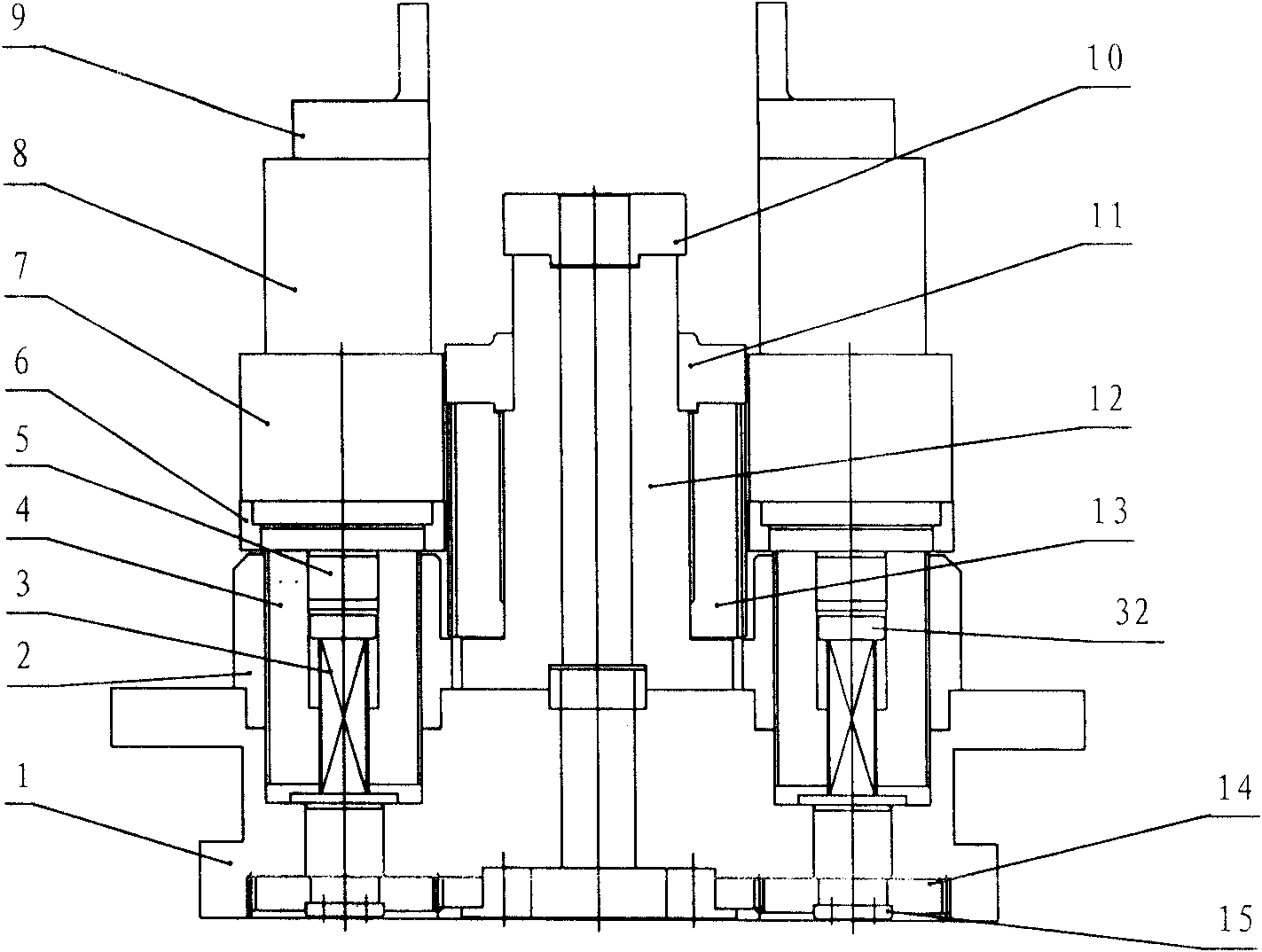

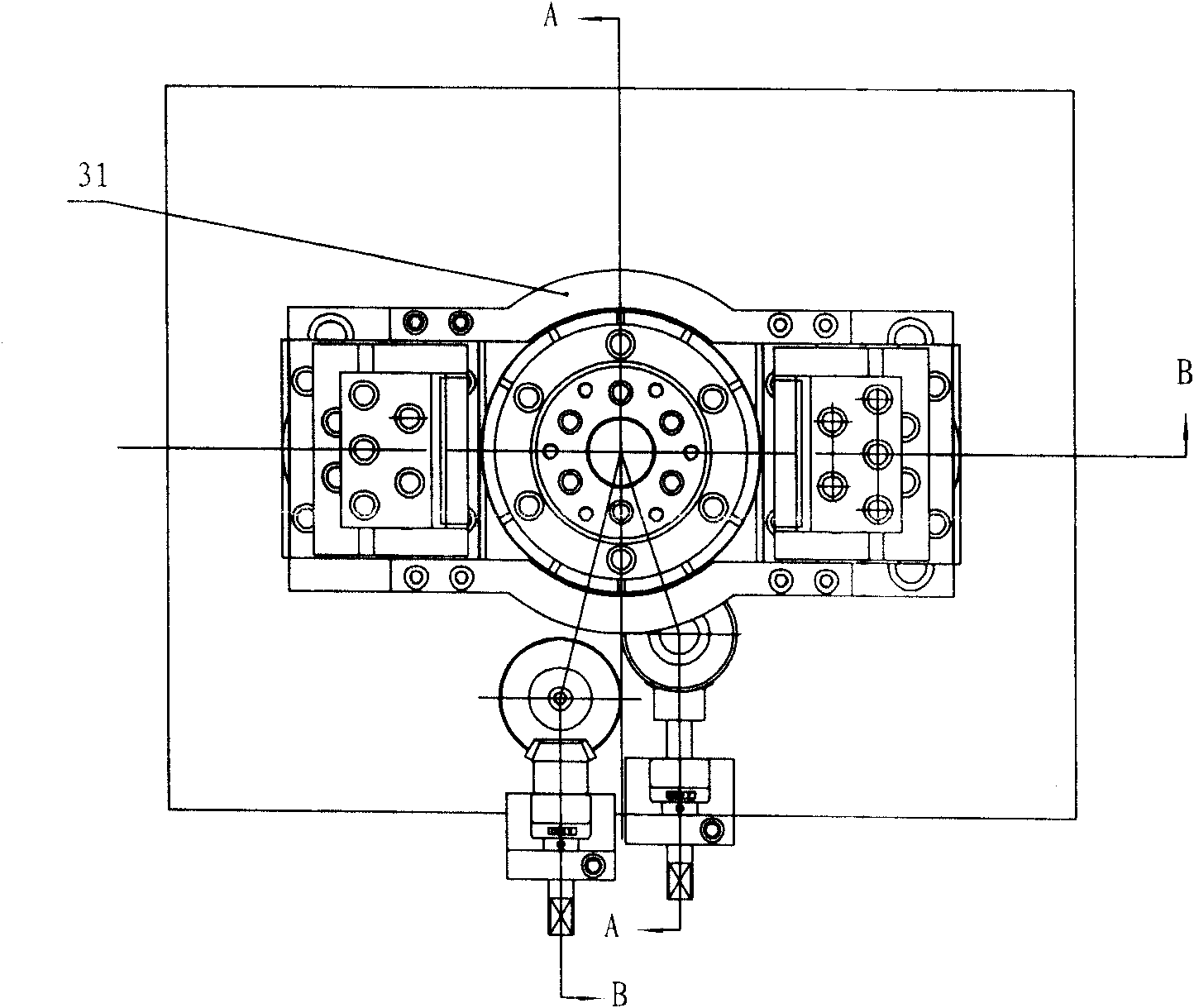

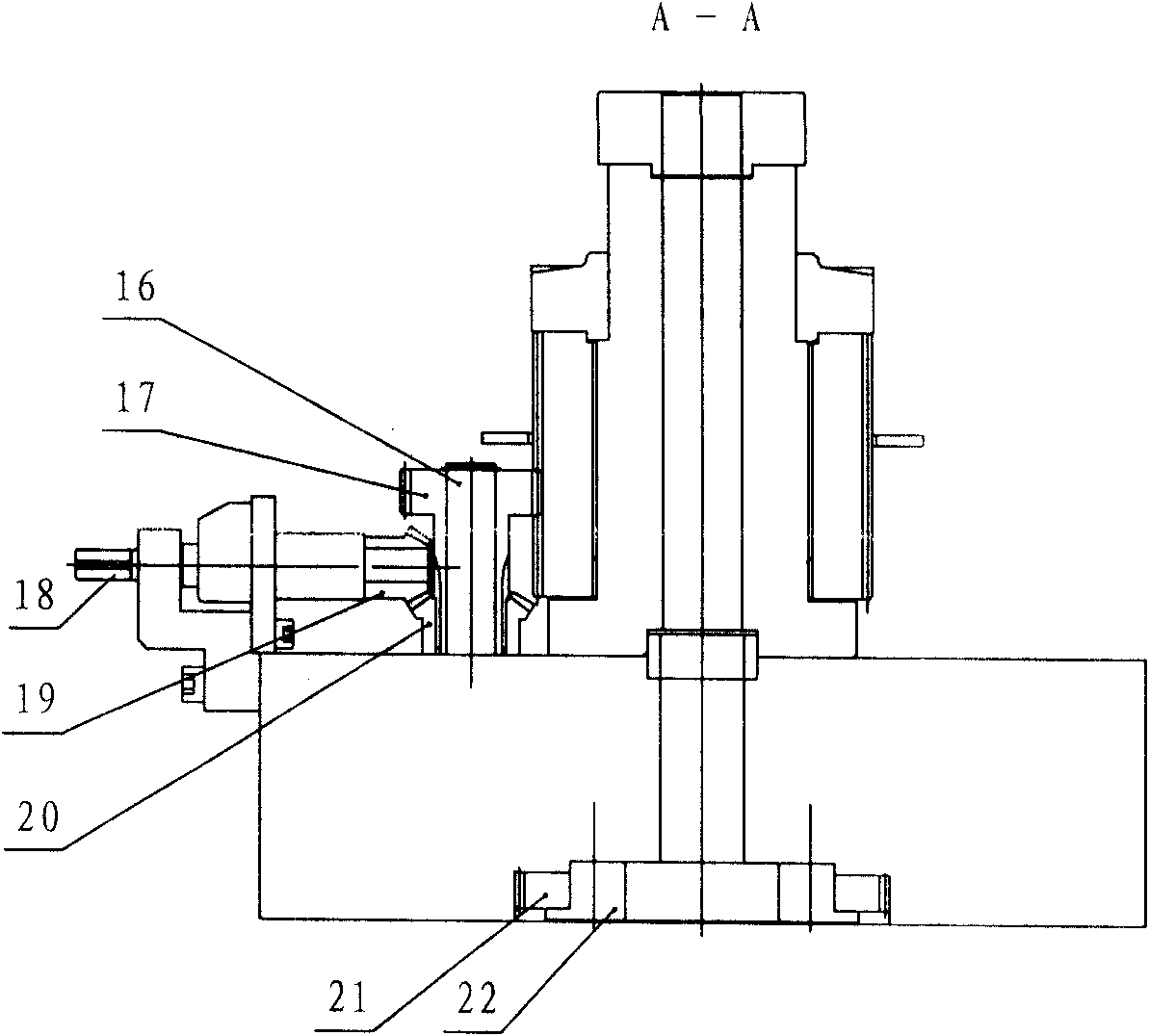

[0013] Among the figure, 1, there are two grooves and a plurality of shaft holes in the base (1), and the fixed screw sleeve (2) is inserted in the groove, with an interference fit between them, and the inner hole of the fixed screw sleeve (2) has threads.

[0014] 2. The head and tail of the adjustment shaft (3) have screw holes, and the upper part is rectangular. The adjustment shaft (3) is inserted into the shaft hole of the base (1), and one end of the center hole of the adjustment stud (4) is a circle. hole, the other end is a rectangular hole matching the adjustment shaft (3), and the outer circle is provided with threads. The rectangular hole of the adjustment stud (4) is inserted into the adjustment shaft (3) and then screwed into the fixed screw sleeve (2). Upper gear (14), shaft cover (15), limit block (32).

[0015] 3. The block adjustment stud (12) and the positioning sleeve (29) are placed on the base (1) and fixed with screws, the gear (13) is screwed on the bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com