Thickener control system

A control system and concentrator technology, applied in chemical instruments and methods, separation methods, precipitation separation, etc., can solve problems such as inconvenient maintenance and difficult operation, save time, improve economic benefits, and avoid the method of discharging water and clearing pools. Effect

Inactive Publication Date: 2011-01-05

CITIC HEAVY INDUSTRIES CO LTD +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the application of the PLC control system improves the system stability, there are still problems such as difficult operation and inconvenient maintenance. Therefore, the improvement and improvement of the control system become the key to improving the automation level of the whole machine

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

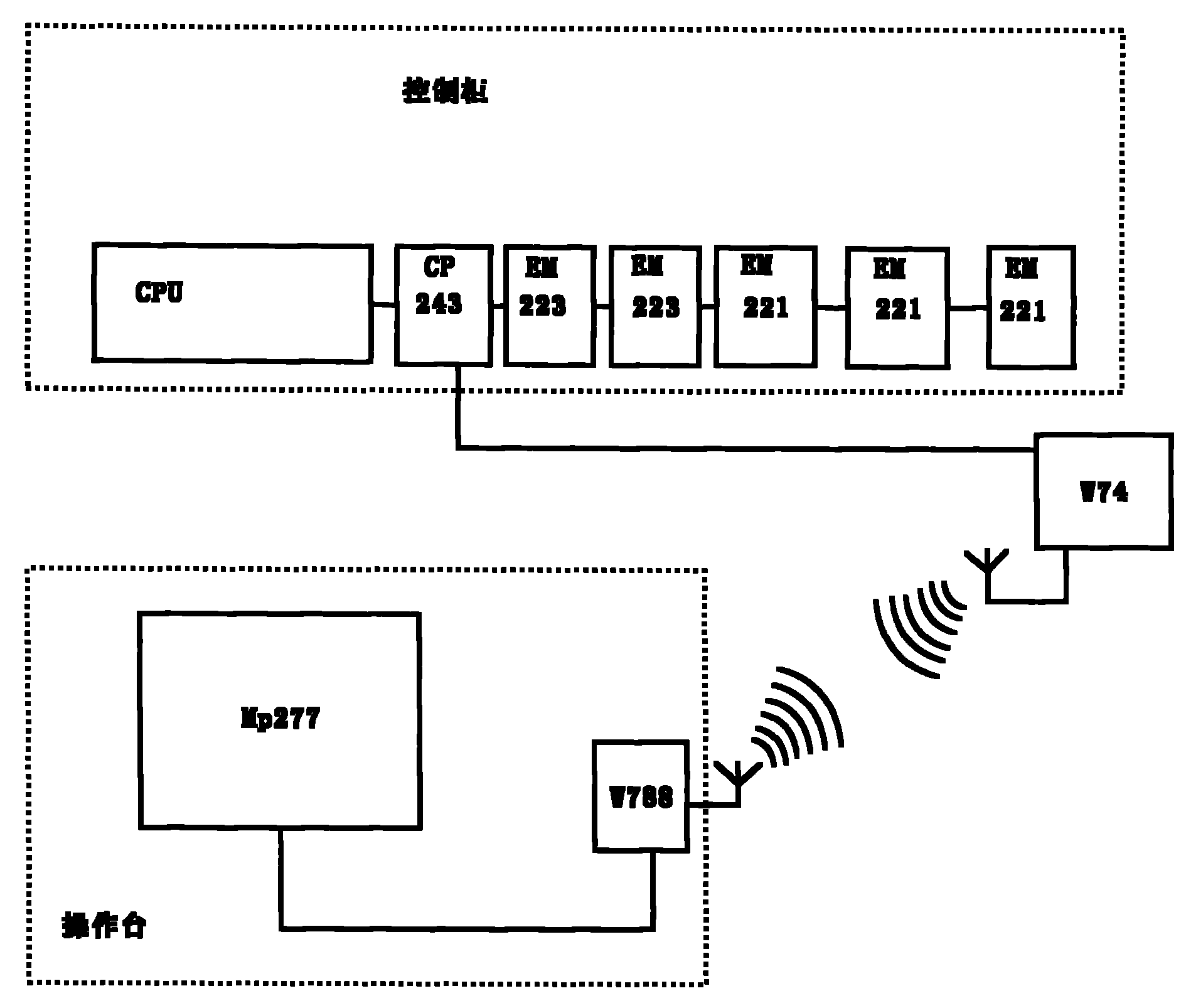

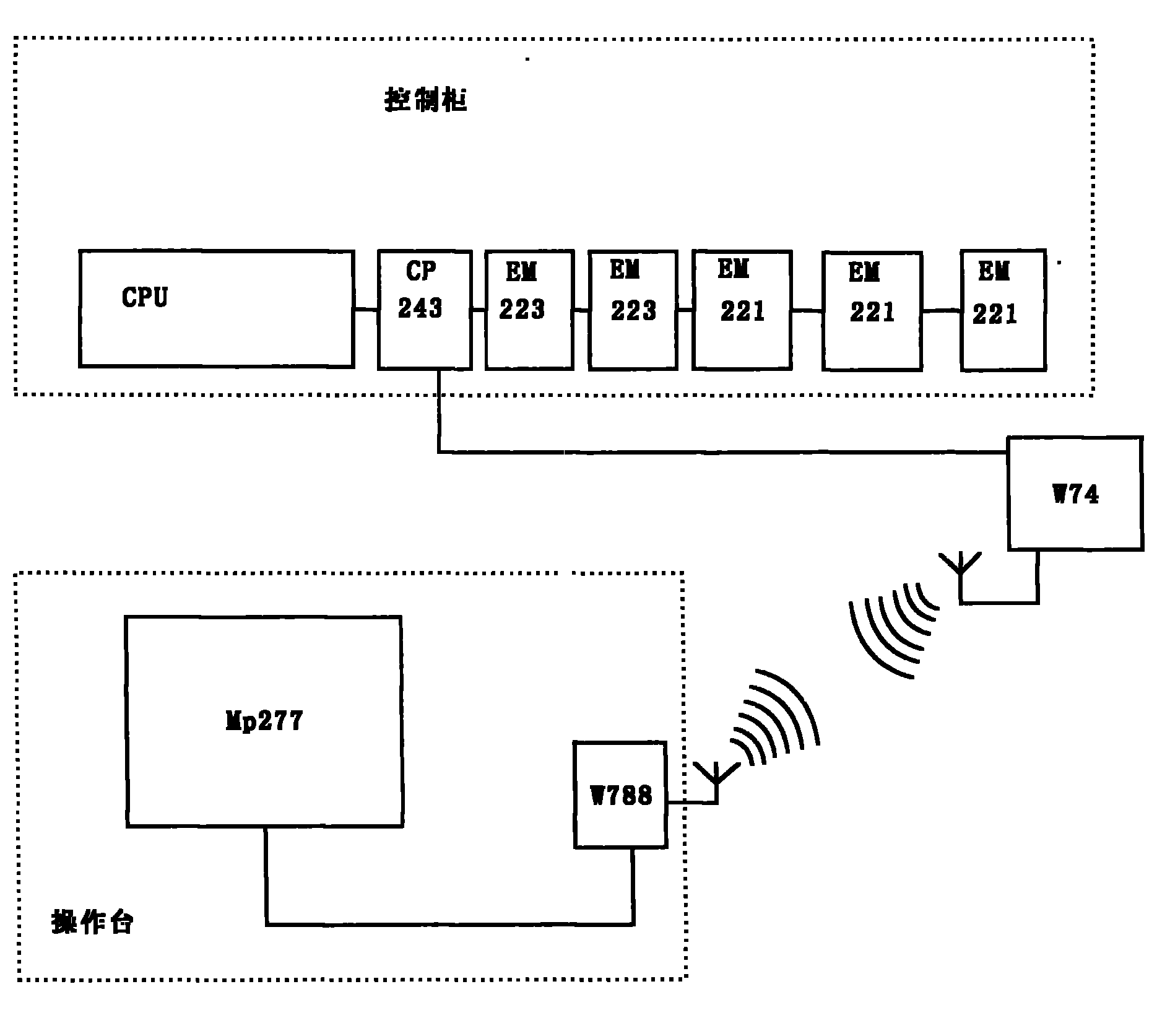

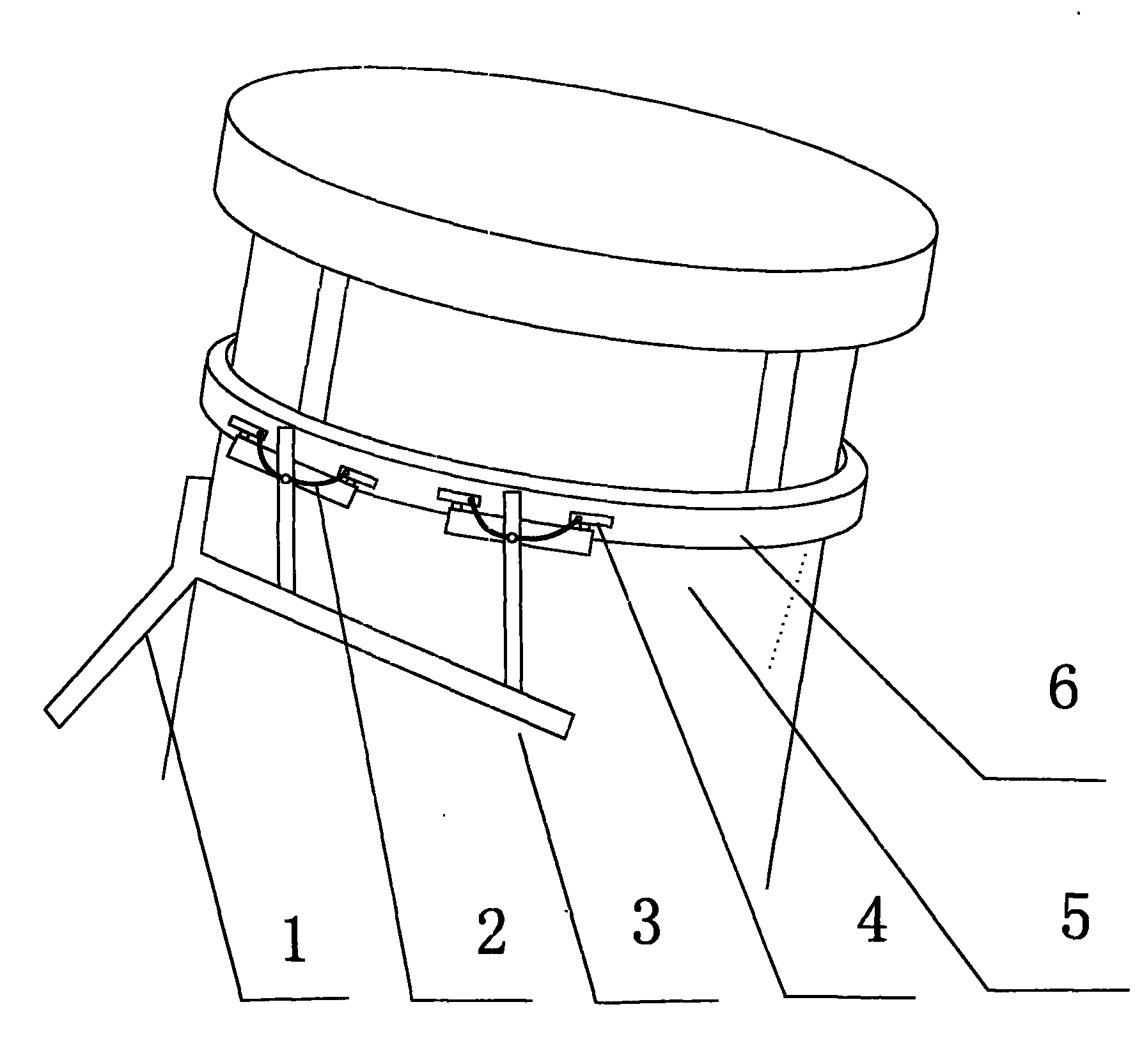

The invention provides a thickener control system. An acquisition system of a field control cabinet sends electrical signals of operating state of the thickener through a control system, a storage system and an executive system so that a rotary bridge, a scrapping and collecting device and a hydraulic system of the thickener can automatically run according to programs; the field control cabinet is connected to a power source by a current collector; the electrical signals of operating state of the thickener are transmitted to a remote console by wireless communication, the remote console controls the field control cabinet by the wireless communication to control operation of the thickener so as to complete the rotary bridge control, the scrapping and collecting device control, the hydraulic system control, fault alarm and interlock control; and remote control, automatic control and manual control are provided. The system can automatically lift rakes one by one, realize mechanical pool cleaning function, avoid water discharge for cleaning, reduce waste, and greatly increase economic benefit of users. The remote operation realizes wireless communication between the rotary PLC controlcabinet and a ground touch screen by Ethernet.

Description

Concentrator control system technical field The invention belongs to the technical field of electric automatic control, and is especially suitable for a concentrator control system for concentrating and purifying suspensions in coal, chemical, building materials and sewage treatment industries. Background technique Thickeners are widely used in coal, chemical, building materials and sewage treatment industries to concentrate and purify suspensions. Especially in today's shortage of energy and resources, the demand for concentrators in industries such as sewage treatment and concentrate extraction will increase. The solid particles in the suspension in the concentration tank settle under the action of gravity, so that the solid and liquid can be separated, and the upper part is clarified water. The sediment deposited at the bottom of the concentration tank is continuously scraped and collected by the scraping device to the ore discharge port at the center of the bottom of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01D21/30

Inventor 朱建峰张涛赵爱东

Owner CITIC HEAVY INDUSTRIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com